By Maurizio Di Paolo Emilio, contributing writer

Portable devices such as mobile phones and tablets require power management techniques to meet the increasingly challenging performance requirements. Consumers are using their smartphones in new ways: They want to display high-definition GPS videos and maps; make two-way video calls; play more engaging games; and stream music. System-on-chip (SoC) projects for this type of application must also comply with stringent heat dissipation targets while meeting the long battery life requirements.

Third-generation “smart” mobile phones combine the traditional mobile phone with functions like personal data assistants (PDAs), digital cameras (DSCs), and music players (MP3s). The rechargeable lithium-ion (Li-ion) battery is the power source for mobile electronics. Its high energy density guarantees greater power in size and weight than other types of batteries. Furthermore, its operating voltage makes it possible to obtain a long life and high conversion efficiency for DC/DC solutions.

Estimating the energy consumption of a mobile device is a fundamental element of the design. The aim is to design the device to minimize its energy consumption. Individual components such as the oscillator, CPU, I/O ports, and analog peripherals must be considered as part of the calculation. Effective energy management presents an increasingly complex range of design challenges. Low battery life contributes to customer dissatisfaction.

The battery

To meet these design goals, the design of the power management subsystem starts with the battery. Factors such as recharge cycles, aging, and temperature can degrade the performance of the lithium-ion battery over time. Proper management and control of a rechargeable battery are essential to optimize battery life.

Battery management consists of three parts: charge monitoring, protection, and control. Battery monitoring and protection ICs are usually supplied with the battery itself. However, charge control is part of the portable device. The charge control devices have evolved significantly over time, implementing lower minimum gate lengths for high-density, high-speed digital circuits but also higher-voltage–capable devices for more analog and power applications.

The linear control topology works well in applications with low-power battery packs that are charged to less than 1 A. However, the switch-mode topology is more suitable for large battery packs that require charging speeds of 1 A or higher. Switching-mode topology is more efficient and minimizes heat generation during charging but can produce electromagnetic interference (EMI) if it is not packaged correctly.

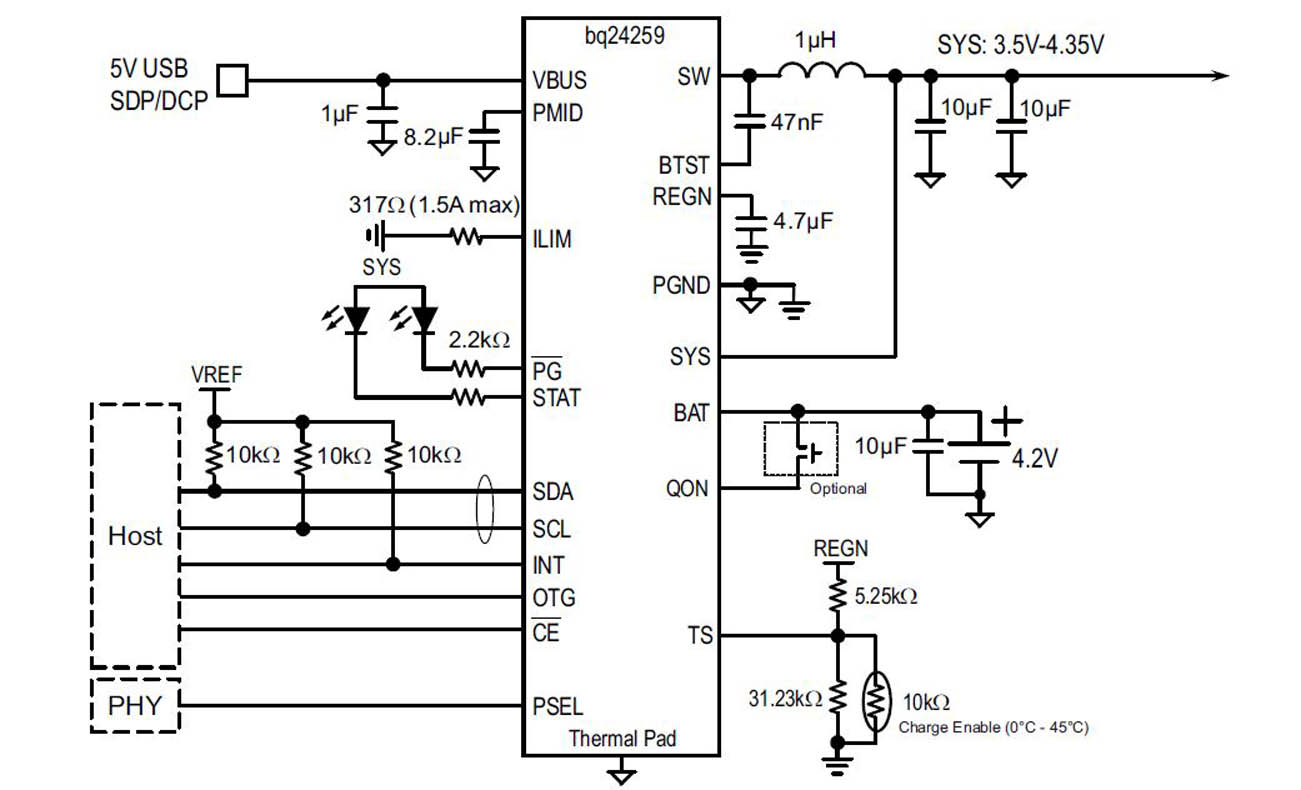

Fig. 1: Texas Instruments’ bq24259 for battery charge management. (Image: Texas Instruments)

The bq24259 from Texas Instruments is a switch-mode battery-charge management and system-power-path management device for a one-cell Li-ion and Li-polymer battery (Fig. 1 ). The IC automatically charges the battery in three phases: pre-conditioning, constant current, and constant voltage.

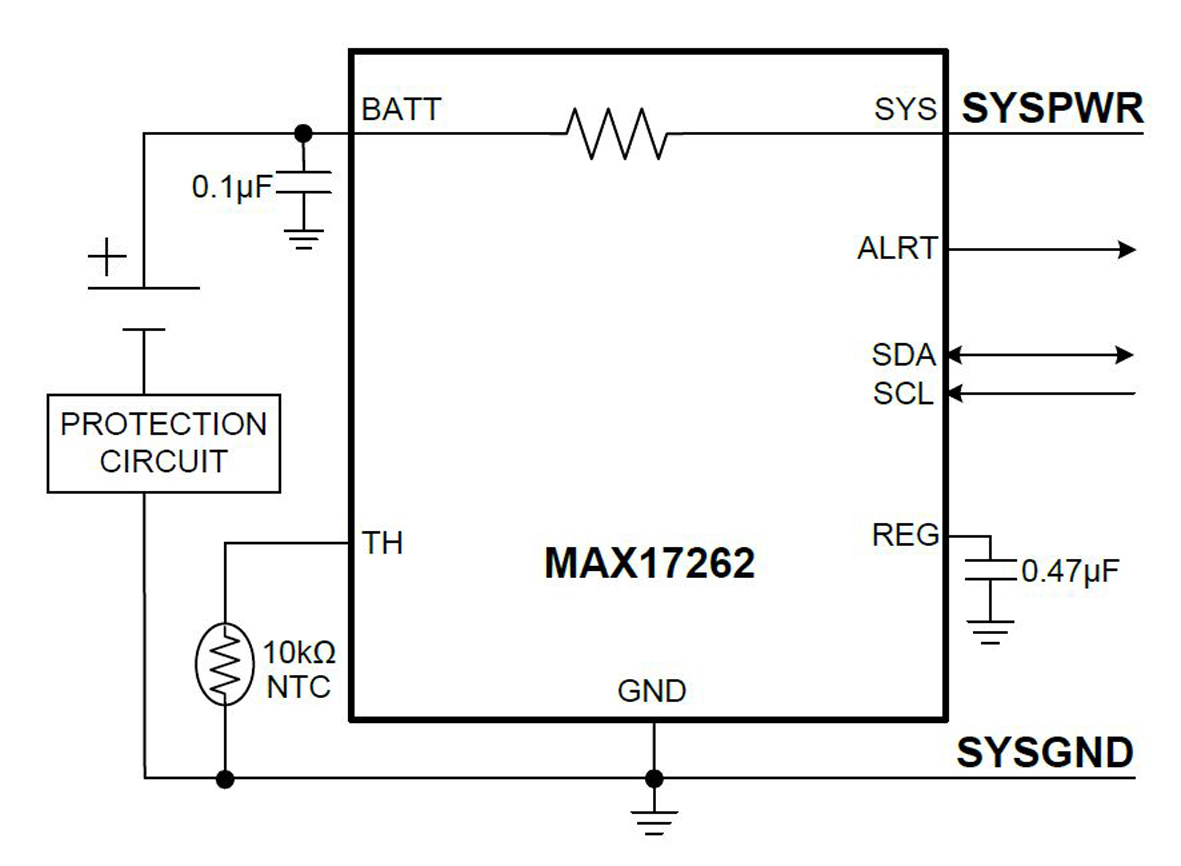

Designers of mobile and portable Li-ion devices can improve performance by extending battery life and providing information on the state of charge (SOC) of the battery using charge level indicators with the MAX17262 single-cell and MAX17263 single-/multiple-cell integrated circuits from Maxim Integrated. The MAX17262 and MAX17263 devices combine the traditional coulomb counting with the new ModelGauge m5 EZ algorithm for the high-precision SOC of the battery without requiring the characterization of the battery itself (Fig. 2 ).

Fig. 2: Simple fuel-gauge circuit diagram. (Image: Maxim Integrated)

Power management for multicore chips

The amount of computation continues to increase in SoC projects to add more functionality via hardware accelerators that perform machine-vision and other deep-learning algorithms. At the same time, however, these powerful multicore chips require solutions that further improve energy efficiency and create more flexible power supply sequences.

The need for lower energy consumption and the ever-increasing advent of mobile devices have directed microelectronics toward increasingly ultra-low-power solutions exploiting environmental energy sources such as kinetics, solar, thermal, and radio frequency (RF). Getting the most out of these sources is not easy. Detection, control, and conditioning are critical factors in the design and can determine the overall efficiency of the energy-harvesting system.

The challenge of a power management system is to provide constant voltage output with maximum efficiency. With the recent advances in microelectronics, low-power systems can manage energy harvesting to meet the low power consumption of the microwatts and nanowatts that involve today’s integrated circuits in different operating situations.

The importance of optimizing energy performance becomes more critical and technically more difficult. Power management integrated circuits (PMICs) are highly programmable, allowing them to support voltage sizing and power supply sequencing required by single- or multicore application processors, as well as all smartphone subsystems, such as the network and stack connectivity (3G, 4G LTE, Wi-Fi, Bluetooth, and NFC), displays, megapixel cameras, and more.

The PMIC must manage up to 30 bus-rails, in addition to the baseband processor with the right combination of voltage and current. SoC designers can improve power management costs by using individual low-voltage and low-current power bars provided by the dedicated PMIC.

Today’s digital modulation techniques compress more bits of data in each RF channel, resulting in a more complex circuit layout with higher “crest factors,” expressed as a peak-to-average power ratio (PAPR). The PMICs give OEM engineers greater design flexibility in the development of smartphone platforms and enable them to launch more models and projects for different markets and for the “life cycle” of that product.

PMIC examples

Solutions offered by NXP, Renesas Electronics, and Texas Instruments (TI) provide scalable, secure, and flexible solutions for various power management applications. These PMICs can support a wide range of devices to extend battery life and reduce power dissipation. All solutions offer programmability, efficiency, and high levels of integration.

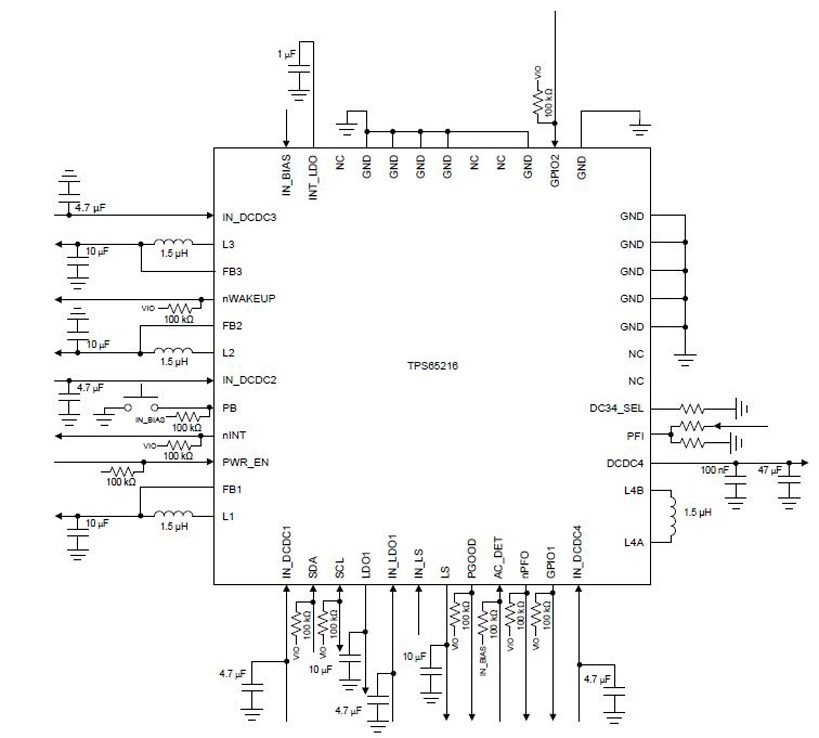

For example, TI’s TPS65216 PMIC is specifically designed to provide power management for the AMIC110 and AMIC120 processors. (Fig. 3 ).

Fig. 3: A typical application circuit of TI’s TPS65216. (Image: Texas Instruments)

NXP offers a series of ICs for various families of i.MX application processors to optimize energy efficiency and software/hardware integration. They integrate both switching and linear regulators with battery management functions.

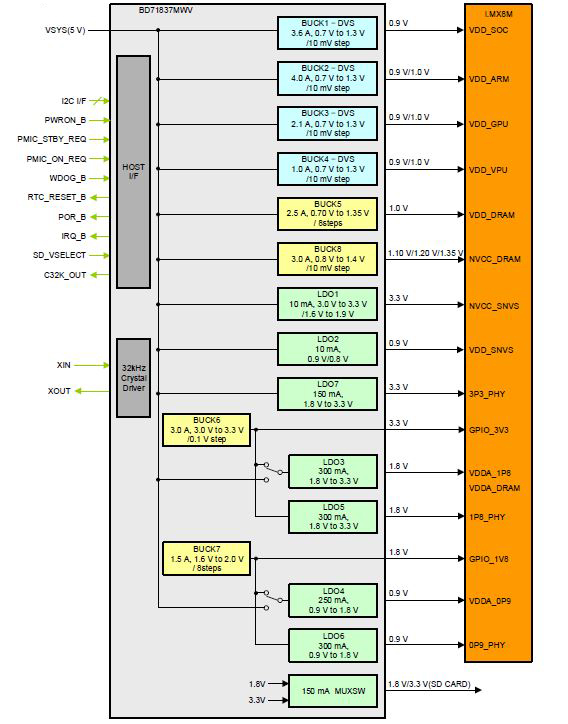

ROHM Semiconductor also continues to support NXP processors through its BD71837MWV. This device integrates all of the power rails required by i.MX 8M processors and system peripherals. I.MX 8M Mini processors allow customers to integrate the voice interface on audio- and video-streaming devices at a minimal cost. Together with the BD71837MWV, ROHM also introduced the BD71847AMWV, which integrates the power supplies for DDR and the IO system. (Fig. 4 ).

Fig. 4: Typical application circuit for ROHM’s BD71837MWV. (Image: ROHM Semiconductor)

The ISL95852A from Renesas integrates power MOSFETs, fault protection, and monitoring functions for three highly efficient synchronous buck regulators. The ISL95852A is offered in a WLCSP package. The PMIC controllers convert the system voltage from a battery or adapter into the three necessary processor voltages required by Intel’s IMVP8 specifications.

Dialog Semiconductor’s DA9070 PMIC integrates a linear charger with a current up to 500 mA and offers several power-saving modes to increase battery life. The integrated PMIC reduces power management footprint by 25% compared to other discrete solutions.

Conclusion

Mobile phones continue their expansion, becoming personal information devices for our daily needs. Energy performance will increasingly represent a design challenge. The internet of things (IoT) demonstrates the need for a wireless world, putting further pressure on the battery life of portable devices, requiring unceasing attention to energy management innovation.

Advertisement

Learn more about Electronic Products MagazineMaxim IntegratedNXP SemiconductorsRenesas Electronics AmericaTexas Instruments