By Gina Roos, editor-in-chief

Subassemblies, modules, and components developed for various military applications, such as avionics, ground vehicles, and portable electronics, all need to operate in a variety of harsh environments, which range from extreme temperatures to high shock and vibration. At the same time, lighter and smaller designs are critical for space- and weight-constrained systems, and durability and reliability are at the top of the list of big concerns. These stringent demands translate into big challenges for connector makers to ensure that the interconnects provide highly reliable and fast connections over extended use and in harsh conditions.

Connector makers also need to consider a multitude of design requirements such as mating cycles for long life, ingress protection, and ease of use. High-speed data transmission capability is also becoming a bigger factor in new communication designs. While component manufacturers need to meet specific military standards and specs, many connector manufacturers are developing their own advanced technologies and processes to provide a higher level of reliability and usability.

Addressing the need for watertight products in harsh environments, Cinch Connectivity Solutions, a Bel Group company, recently released its Cinch Mil/Aero Circulars’ DMS-TP series . These connectors are waterproof when temporarily immersed up to 300 meters, and they are resistant to corrosion. They are also designed for ease of use with scoop-proof shells. The nickel-plated brass shells allow the connectors to withstand prolonged use in the presence of oil, gas, sand, mud, hydrocarbons, and salt.

The Cinch circular connector series offers a full range of frequencies, insulation resistance, dielectric withstanding voltage, operating voltage, or capacitance. They are also available in hermetic sealing in any circular connector configuration. These glass, ceramic, or epoxy-sealed packages can be used in components or assemblies in harsh-environment applications that demand no leakage even under extreme changes in temperature, pressure, humidity, and intense vibration, said the company.

A new circular connector from ITT Cannon also addresses ingress protection. Cannon’s Nemesis II CBA 20+ meters is a high-speed, high-mating and quick-termination interconnect that has been tested for water submersion to 20+ meters (65.6 feet). The miniature circular interconnects, designed for soldier-worn applications, operates in extreme and harsh environments so that it can be used in battlefield communication devices and applications. It provides power, signal, and data in a smaller integrated design to deliver reliable communications in a reduced weight solution. In addition, the breakaway functionality allows soldiers to quickly disconnect/reconnect their cables and equipment if they become caught, and the connector easily terminates to wire, PCB, and flex circuits.

“Soldiers operate in a wide range of terrains and harsh environments, so their equipment is constantly exposed to the elements like dust, dirt, mud, and water,” said Wayde King, product manager, ITT Cannon. “Cannon Breakaway functionality, which is featured on our Nemesis II CBA and MKJ4 Nett Warrior-Style interconnects, allows warfighters to quickly mate and de-mate the connector from devices in a matter of seconds — minimizing equipment damage and helping them stay better-connected and better-protected in the field.

“The demand for interconnect solutions that can withstand water ingress or water submersion is also becoming increasingly important,” he added. “Our Nemesis II CBA is designed and tested for water submersion to 20+ meters (65.6 feet) — among the highest in the industry.”

Along with challenges in harsh environments, military connector designs face size/weight/speed and demand for high-speed data, signal, and power, said King. “The trend toward miniaturization will continue to drive the development of lighter, smaller interconnects that push data transfer rates, reduce overall weight, and relieve cognitive burden. Soldier-worn equipment and devices will evolve, driving the need for further changes in electronic connectivity.

“Augmented and virtual reality devices, smaller and more advanced military-grade radios and tablets, and helmets embedded with smart goggles, eye movement monitors, and advanced imaging technology are a few examples of what the future — or near future — may hold,” he said.

Cannon also introduced a lightweight connector for mobility applications. The Rock-in-Lock (RIL) latching connector is a flash-drive−sized, low-profile quick connect that attaches to a helmet or tablet without any tools. It can be worn on a soldier’s helmet or attached to field-use computers, tablets, and communication units.

Low-profile, lightweight, and capable of transferring a lot of power and data to operate various devices from augmented reality (AR) goggles to tactical combat radios, the Rock-in-Lock interconnect offers a quick-connect mechanism and is designed for single-handed use that allows the user to blindly install the mating interface without any tools.

“When the difference in mission success or failure is split-seconds, we are continuously challenged by how to transmit data, power, and signal faster so that soldiers have the information they need to make snap decisions,” said King. “The use of high-speed copper in soldier-worn connectors and cabling solutions offers potential because of its security, durability, and shielding properties. However, using copper in cabling and contacts creates another set of engineering challenges because it often means a significant redesign of the connectors.”

Small and reliable

Another small connector comes from Omnetics. The company’s Nano 360 circular connectors are designed for a variety of high-reliability applications that must withstand shock, vibration, and temperature requirements. Designed to replace MIL-DTL-38999 and D-sub-miniature connectors that are often too large and too heavy, said Omnetics, the Nano 360 connectors are designed to significantly reduce size and weight while maintaining high reliability.

The connectors are extremely lightweight at 0.6−2.3 grams, including wire. In addition, the size and weight has been reduced by as much as 3× compared to standard .050-inch−spaced circular connectors. They also feature gold-plated pins and sockets for higher insertion and withdrawal forces to ensure retention in rugged environments and are rated for over 2,000 mates/de-mates.

Omnetics said that the Nano 360 connectors use the same key elements of Nano-D connectors that have passed military specifications for shock, vibration, durability, temperature, and mating/de-mating force and passed specifications for MIL-DTL-32139. They are available in four shell types — plastic, threaded, breakaway, and twist-lock — with key advantages around weight, sealing, and ease of use.

Also designed for military applications that require twist-lock or threaded mating systems, ODU offers its Advanced Threaded Technology connectors for harsh-environment applications. These connectors provide a highly reliable connection for military applications that need more security or operate in tough environmental conditions, including temperature, pressure, or vibration.

These threaded connectors offer a wide operating temperature range, high vibration resistance, up to 2,000 mating cycles, and an IP68 rating. The family is available in different individual contact configurations (signal, low/high voltage, coax/triax), along with a variety of inserts. Touting reliable high-speed data transmission and a lightweight and easy-to-use design, the threaded connectors can be used in soldier communication applications, unmanned systems, and military vehicles.

Speed matters

High-speed data communication is a critical concern for many military systems, and connector makers are delivering new rugged and high-speed designs that can handle harsh environments.

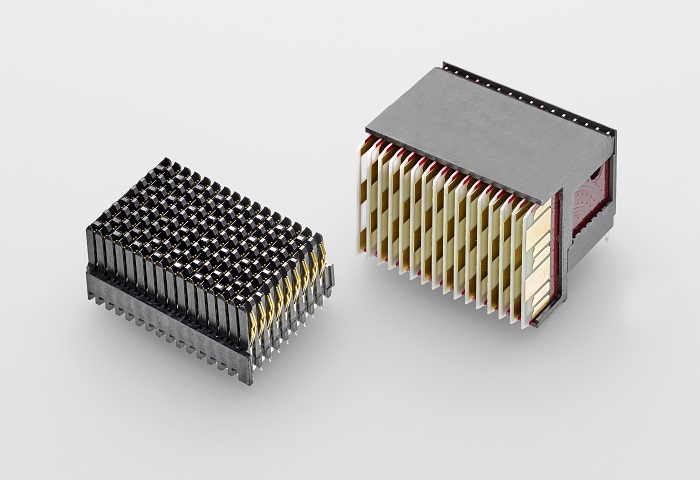

One example from TE Connectivity is its MULTIGIG RT 3 and 2-S rugged backplane connectors built for speed and ruggedness. The MULTIGIG RT 3 is TE’s fastest rugged backplane connector, clocking speeds of 25-plus-Gbits/s for embedded computing or VPX systems. Because they are ruggedized, they can meet both military and space environments.

Key features of the MULTIGIG RT 3 connector include quad-redundant contacts to meet VITA standards and high-vibration environments and its lightweight thermoplastic body that makes it one of the lightest backplane connectors in the market. The modular design makes them interchangeable with legacy MULTIGIG RT 2 and RT 2-R connectors. Military electronics applications include Command, Control, Communications, Computers, and Intelligence (C4); Information, Surveillance, and Recon (ISR) electronic warfare systems, avionics, ground defense, missile defense, and systems designed for outer space.

Another new high-speed Ethernet connector comes from Amphenol Socapex. This Cat. 6A, 10-Gbits/s Ethernet connector is housed in a MIL-DTL-38999 Series III shell. The TVµCom-10Gb+, a member of the new range of Amphenol Socapex µCom Ethernet connectors, is designed to meet military standards for miniaturization, speed, and robustness in harsh environments.

The µCom connector combines 10-Gbits/s Ethernet speed of the classic µCom-10Gb+ with the ruggedness of the 38999 Series III shell. The connector exceeds 10 Gbits/s according to the IEEE 802.3an-2006, 10GBase-T standard, while the 38999 series III size 11 shell provides environmental resistance similar to MIL-DTL-38999 Series III, said Amphenol. Target applications include battlefield communication, ground vehicles, and military avionics.

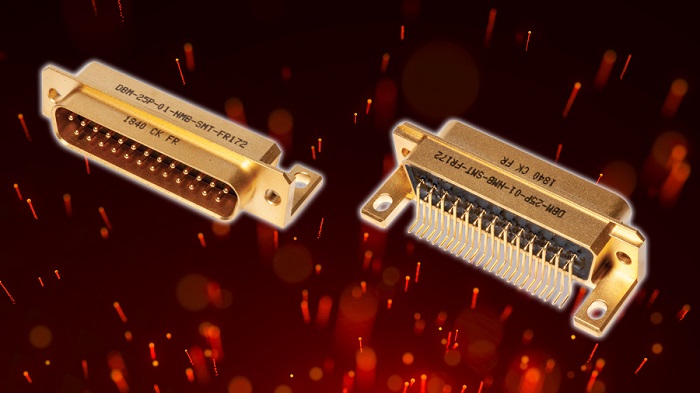

Even tried-and-true D-sub-miniature connectors continue to get upgraded for higher reliability, weight savings, and smaller size. A good example is C&K’s space-grade D-sub surface-mount connectors that can also be used in military avionics applications. A key feature of these D-subs is the design — it doesn’t require plated holes to be drilled into the PCB, which frees up one side for use by other components, thus delivering a simpler, lighter, and smaller connector.

In addition, C&K leverages its in-house expertise to design a smaller form factor than the traditional six-part copper-alloy stamped shell method. C&K said that this delivers up to 50% less weight compared to standard through-hole technology connectors and better dimensional capability.

Designers and buyers of military interconnect products can expect continued development in the areas of speed, reliability, and miniaturization as new technologies, ranging from AR devices and helmets with smart goggles to advanced radios and imaging, are designed for military applications.

This article was originally published at EET’s Military & Aerospace Designline .

Advertisement

Learn more about Electronic Products Magazine