By Carolyn Mathas, contributing writer

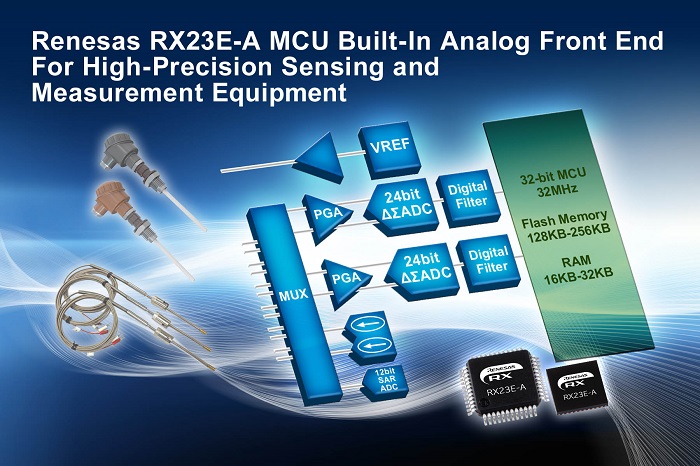

Combining a high-precision analog front end (AFE) and a microcontroller (MCU) on a single chip, Renesas unveiled the RX23E-A Group MCUs, its first solution that measures signals with better than 0.1% precision without calibration. The RX23E-A Group targets applications such as manufacturing and test and measurement, in which the measurement of high-precision analog signals for temperature, pressure, weight, and flow are critical. The RX23E-A Group enables sensor data to be measured accurately and reliably by reducing noise characteristics and temperature drift characteristics to low levels.

The Renesas RX23E-A Group of MCUs enables sensor measurement with a precision of 0.1% without calibration.

RX23E-A MCUs are based on the RXv2 core with operating speeds of 32 MHz, a digital signal processor (DSP), and superlative floating-point unit (FPU) calculations. This enables implementation of adaptive control using temperature data and inverse matrix calculations using six-axis distortion data.

Features of the MCUs also include AFE precision, including offset drift of 10 nV/°C, gain drift of 1 ppm/°C, and 30-nV rms noise, previously achievable only with dedicated A/D converter circuits with high-precision operational amplifier ICs. The solution enables implementation of high-precision sensor measurement, computation, control, and communications, all in a single chip. This allows system manufacturers to reduce component count, save space, and simplify system design. It also enables distributed processing with MCUs, accelerating end-point intelligence.

Samples of the RX23E-A Group of MCUs are currently available, with mass production planned for December 2019. They are available in 48-pin QFP (7-mm square) and 40-pin QFP (6-mm square) packages.

Advertisement

Learn more about Electronic Products MagazineRenesas Electronics America