By Dave Sroka, staff marketing engineer, Microchip Technology

Over the last 10 years, automotive infotainment system features have significantly changed. In 2009, leading automotive publications ranked both built-in navigation systems and DVD players in the top five most important features in vehicles. Because of the rise of smartphones, built-in navigation systems have now fallen to the wayside, and driver convenience features — such as smartphone interfaces (i.e., Android Auto, Apple CarPlay) and fast Universal Serial Bus (USB) charging — have climbed to the top.

At the junction of these features lies one key technology — USB. A well-known technology among consumers, USB continues to output new specifications from its industry organization, USB-IF, and system designers continue to find value in the technology. Engineers at top automotive OEMs and Tier One suppliers have been integrating such convenience features into their product designs for a few years. This trend is sure to continue as applications on smartphones continue to evolve, more bandwidth is delivered to vehicles, and consumers desire quicker charging for electronic devices.

In the case of a vehicle’s smartphone interface, USB is used as the transport layer to stream the handset display or data to the head unit. For faster charging, it is the USB Power Delivery (PD) specification that outlines how power contracts are negotiated/finalized and what level of power can be delivered to the consumer device. While the USB specifications, compliance testing, and USB chips are architected to perform most of the heavy lifting, system integration of all components, including head unit hardware, head unit software, and media hubs, must be engineered.

Key considerations for USB 3.1 system designs

Pushing down to the next technology level, many factors must be considered to finalize the system:

- Bandwidth needs (USB 2.0 Hi-Speed or USB 3.1 SuperSpeed)

- Mobile app support required (host-/device-swapping capability needed)

- Number and type of ports needed (one, two, three, or four/Type A or Type C)

- Type of hardware interface (USB Host or USB Host/Device port)

- Power level of USB charging (1.5 A, 2.0 A, 3.0 A, etc.)

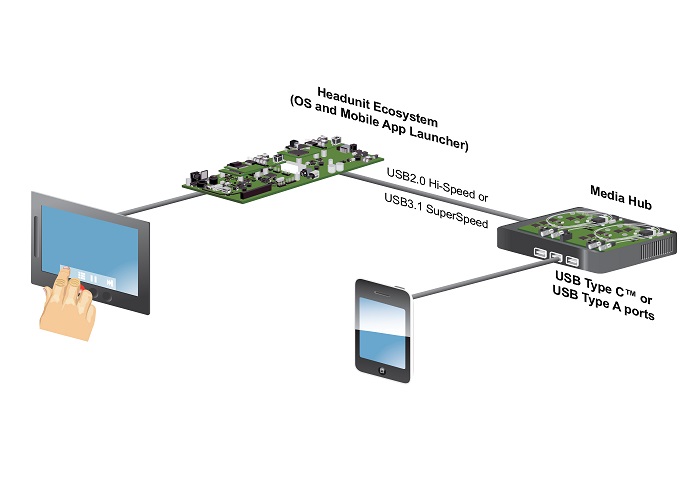

Fig. 1: Factors to consider when designing a USB system.

Because of this, it’s important that OEMs can add capabilities without changing system architectures. Microchip, for example, has developed an extensive automotive USB portfolio that supports consistent system integration themes so that OEMs can migrate systems while maintaining architectures.

For example, if an OEM is using a USB 2.0 solution in which they connect to a USB host-only port in the head unit, they can readily move to a USB 3.1 solution that requires only a USB host port solution (i.e., a host reflector feature). Both of these solutions will use the same native USB class driver (i.e., a Communication Device Class and Network Control Model) to support Apple CarPlay. Therefore, the work that was completed on the USB 2.0 solution, including launching the mobile interface applications, can be the same for both chips. Likewise, Microchip offers support for a USB host/device connection on the head unit with a feature called FlexConnect that can swap functionality of its hub port from device to host and back.

With all of this in mind, the designer has an option to use a FlexConnect methodology for supporting the host/device swapping of an iPhone executing CarPlay or a multi-host reflector methodology. One of the primary differences between the methodologies is the amount of bandwidth that will be available for the CarPlay session.

With FlexConnect, the iPhone — which becomes a USB host during CarPlay — will have all of the USB 2 bandwidth (480 Mbits/s) at its disposal. With the multi-host reflector, the iPhone would share the 480-Mbits/s bandwidth with the USB host in the head unit. The decision is left to the system architects to choose the methodology that best meets their system needs. In both cases, no custom drivers are required. The multi-host reflector feature and FlexConnect feature are offered in both USB 2.0 and USB 3.1 automotive hubs.

Because of this, an infotainment head unit system with a media hub can be readily migrated from USB 2.0 Hi-Speed to USB 3.1 SuperSpeed in terms of the functional chip blocks. Consistent feature sets and USB class driver provide identical user application support while reducing system-validation tasks, design risk, and time to market.

Trade-offs of migrating from USB 2.0 to USB 3.1

While simple migration from USB 2.0 to USB 3.1 is possible, there are some areas that need to be evaluated when considering a migration to a USB 3.1 SuperSpeed solution. Foremost is the fundamental difference of supporting a 5-Gbits/s data stream versus a 480-Mbits/s data stream. Printed-circuit-board design, component placement, connector quality, and cable distance can all impact signal integrity. For initial implementations, higher cable and component cost should be expected until the savings of high volume and economies of scale can be achieved. The overall performance and bandwidth that can be obtained must be measured against these factors.

For Type-C ports implementing USB Power Delivery 3.0, with the capability to charge up to 100 W per port, it is critical to offer a consistent architecture with the proper control functions. Temperature must be controlled to ensure proper operation and long-term reliability, as well as proper shutoff mechanisms if necessary.

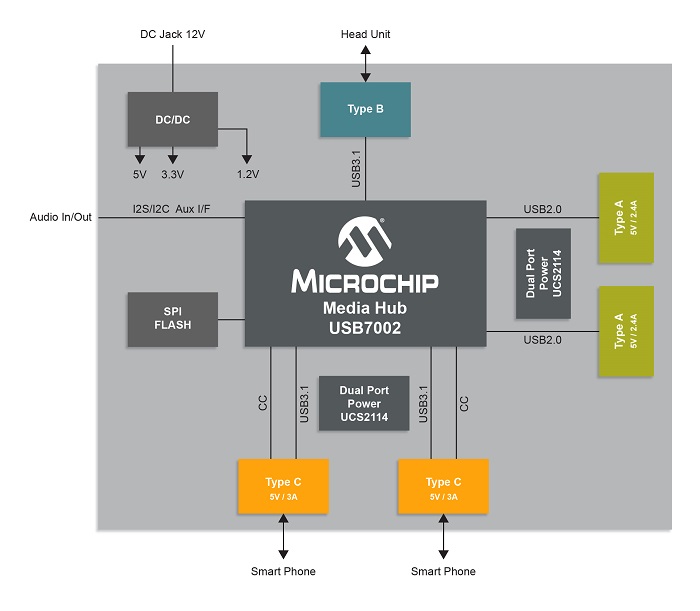

For example, Microchip has developed a consistent functional block diagram for USB 2.0 and USB 3.1 that has maintained the same architecture. Here, the integrated microcontroller in the hub executes the Power Delivery stack, interfaces to the port controller, and manages the power plane of the media hub. This architecture with a centralized microcontroller can perform multiple functions concurrently, including Power Delivery stack, real-time power balancing between the USB ports, and thermal response by power throttling between distinct power banks.

Fig. 2: The block diagram for Microchip’s recently announced USB7002 includes the same architecture as USB 2.0 SmartHubs, making it easy to migrate systems.

By contrast, USB Power Delivery solutions architected per port must incorporate a separate control function, typically in a discrete microcontroller to execute power balancing, power throttling, and temperature control. This is why Microchip’s SmartHub families have always included an integrated microcontroller, as they support these functions with minimal to no additional cost added to the bill of materials (BOM).

Finally, the power-balancing and thermal algorithms can be migrated across platforms or tuned to the specific needs of a vehicle model. For example, a pickup truck could have a different power-balancing model than a passenger sedan.

As mobile interface applications continue to gain in popularity, driving more and more bandwidth and the need for faster charging, it is critical to think of all of the system trade-offs. These include the overall speed of the USB technology needed, USB ports available for the head unit, the bandwidth needed for mobile interface applications, the power delivery experience that is to be provided, and the software/driver structure that needs to be maintained, as well as overall system cost and time to market.

Keeping all of these factors in mind, engineers can tailor their systems to their needs while offering migration paths that minimize design risk and time to market for evolving infotainment ecosystems.

Advertisement

Learn more about Electronic Products Magazine