By Ravindra, Munvar, systems engineer in the medical systems group, Texas Instruments

Medical imaging, specifically ultrasound, is undergoing a significant transformation. In addition to high-performance cart-based ultrasound systems, it’s now possible to use a handheld device to accomplish high-quality ultrasound imaging. Thanks to advancements in semiconductor technology, ultrasound smart probes are becoming smaller and portable, enabling access to healthcare beyond medical offices and hospitals.

An ultrasound smart probe is essentially a portable ultrasound that has the entire front end and almost all of the back-end hardware integrated into it. With reduced power consumption and size, a smart probe processes data, while maintaining signal quality, and displays images on a mobile device using either a high-speed USB or wireless connection.

The day is fast approaching when most doctors will carry a smart probe unit in their pockets, similar to their stethoscope, by which they can not only hear, but also see inside the body—potentially leading to a market of a few million units worldwide within the next decade, complementing standard ultrasound systems. But shrinking the system down to a handheld device is no easy task, and presents many challenges.

Here are some of the most significant challenges smart probe designers face.

Powering the unit

Powering a smart probe with very low noise and ensuring that the power supply itself does not consume high power are two tricky challenges. Designers of smart probe power supplies must work within a very small area and height, while achieving efficiencies greater than 90% with low power being consumed while idle, and most importantly, with low noise. Most manufacturers need their power supplies to switch below 1 MHz and synchronize to an external clock to minimize harmonics interference in the ultrasound operating frequency range of 2-20 MHz. The size vs. efficiency trade-off is a huge challenge.

Size

Twenty years ago, a 64-channel ultrasound system consisted of multiple A4-sized boards each for transmitting, receiving, analog-to-digital conversion, beamforming, and processing, which were interfaced to a backplane and connected to a standard computer. Today, a complete 64-channel smart probe front-end board needs to be smaller than the size of a credit card (85 × 54 mm). However, even with all the advancements in technology and high levels of integration, it is still no small feat to achieve this level of miniaturization.

Channel count

Processing a higher number of channels simultaneously leads to better image quality. Most cart-based scanners today have 128 channels or more. Initial smart probes had either eight or 16 channels integrated inside the probe head; these channels had to be connected to a larger system for processing.

Currently, manufacturers are trying to integrate as many as 64 or 128 channels into the probe. To achieve such channel densities, they can now leverage new, commercial-off-the-shelf devices, like the highly integrated front-end devices from Texas Instruments (TI).

As examples, the TX7332, a 32-channel transmit analog front end and the AFE5832LP, a 32-channel receive analog front end, enable designers to use only two devices each to accommodate 64 channels. Devices like these energize the transducer to generate ultrasound pulses, process the received echo, and convert to digital signals in order to generate an image.

These front ends still need additional devices, like processors or field programmable gate arrays (FPGAs), to control them and process the data generated. The challenge is to pack as many of these devices as possible to improve image quality by increasing channel count within the same power budget.

Power per channel

A 128-channel cart-based ultrasound scanner consumes about 500 W to 1 kW of total power. A handheld smart probe has a power budget of only 3-5 W, so it’s not too hot for the doctor to hold or the patient to feel, and it potentially can operate from a battery. This low wattage means that there’s no room for cooling mechanisms like fans, which could cause vibration and result in a blurry image. Designers must incorporate mechanisms to ensure that probes stay within their power budget, ranging from putting some devices to sleep while they are idle to completely powering off devices when they are not in use. Quick turn ON/OFF is very important to help achieve this.

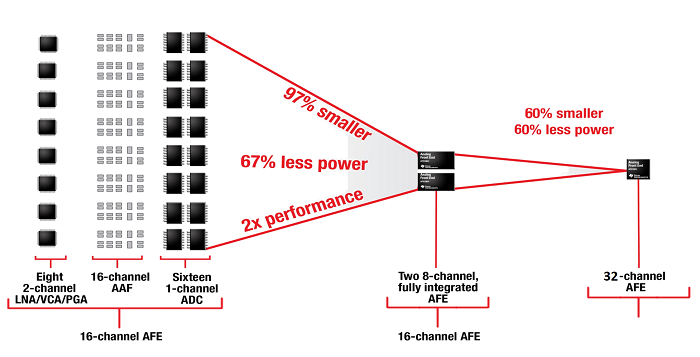

Fig. 1: Advancements in semiconductor technology have dramatically eased ultrasound size and power constraints.

Data processing

Data processing is impacted by multiple factors, including the number of channels, expected power consumption, and data transmission bandwidth. In a 64-channel system sampling at 40 MHz, the front end generates a massive 5.12 GB of data per second, which cannot be transferred directly to a tablet or a mobile device. Even if that data were transferred by some means, the device would not be able to process it in real time. Hence, this data must be pre-processed and converted to a manageable size before sending it to the display unit. The amount of processing is based on trade-offs between the display unit’s power, bandwidth, and processing capability. Most designers use ultra-low-power FPGAs and processors for data processing and controlling the front end.

Data transfer

For wired probes, interfaces like USB 3.1 and higher, using USB Type-C, can be an advantage when providing the necessary power and high data transfer bandwidth to the display unit. But for a truly mobile smart probe, the data has to be transferred wirelessly. There are multiple wireless communication protocols like Wi-Fi (802.11n, 802.11ac, 802.11ad, or 802.11ax standards), which are available commercially; however, these can be limited by interference in their bandwidth when multiple devices use the same band. Other standards like 802.11ah (sub-1 GHz) exist, but have limited bandwidth.

Data interpretation

The biggest smart probe challenge is enabling the analysis of a large amount of data quickly and efficiently. Today, accurate interpretation requires many doctors to analyze the data, and there are significant capacity and time constraints. With high-speed connectivity, data can be sent to servers at remote locations for rapid analysis. With the rise of big data analytics and artificial intelligence, image comparison and interpretation can happen online in real time, resulting in an immediate diagnosis.

Conclusion

The next big wave in medical imaging is coming in a very small size. As designers of ultrasound smart probes resolve challenges and get better devices to market at a lower and more affordable price — and in a smaller size but still with connectivity — the medical world will witness the rapid adoption of smart probes. From a hospital in a developed country to a telemedicine center in a developing country to diagnosing injured soldiers in the field, the rapid evolution of ultrasound smart probes is changing the landscape and helping provide better care.

About the author

Ravindra Munvar is a systems engineer in the medical systems group at Texas Instruments, where he primarily supports customers and reference design development. Ravindra has extensive experience in the design and development of medical imaging devices. He has a bachelor’s degree in engineering from Karnataka University in India.

Advertisement

Learn more about Electronic Products MagazineTexas Instruments