By Maurizio Di Paolo Emilio, contributing writer

The requirement for ultra-low-power has been the most important electronic design criterion in recent years. Levels have dropped dramatically in many cases from mW to µW or nW. As a direct consequence, new techniques have also been developed to address the energy problem. The combination of ultra-low-power microcontrollers (MCUs) and energy harvesting has given rise to a wide range of applications that previously were not possible, thus increasing the level of autonomy of electronic devices. Energy harvesting is the conversion of ambient energy present in the environment into electrical energy using different methods such as thermoelectric and vibrational.

Energy consumption and the need to replace or recharge the battery remain a key challenge for the adoption of the internet of things (IoT), particularly for commercial and industrial applications. Many low-power portable IoT devices can work forever, powered by energy harvesting, without the need to replace the battery or recharge it.

Atmosic Technologies and Matrix Industries have announced a collaboration to improve the energy efficiency of industrial IoT (IIoT) solutions. The combination of Atmosic's ultra-low-power technology and Matrix's thermoelectric technology will reduce environmental impact and battery maintenance costs.

The holy grail of energy harvesting is allowing devices to operate without batteries in remote locations. The combination of low-power design and energy harvesting techniques can create IoT applications with connectivity, processing, and tracking functions.

Thermoelectric energy harvesting

Matrix is working to increase the efficiency of harvesting technology based on the thermoelectric effect. The thermoelectric effect converts the temperature change of material into electrical voltage and vice versa. The best thermoelectric material conducts electricity well and offers good thermal insulation.

The heat supplied is converted into electricity by a thermoelectric converter that uses the Seebeck effect. The current thermodynamic efficiency of the materials available today is around 15% of the Carnot limit. This is due to the difficulty of decoupling the electrical conduction from the thermal conduction. The progress of nanomaterial synthesis techniques and the development of new polymers offer opportunities for the development of a generation of thermoelectric materials that are more efficient, low-cost, and mechanically flexible, for various applications such as biomedical devices.

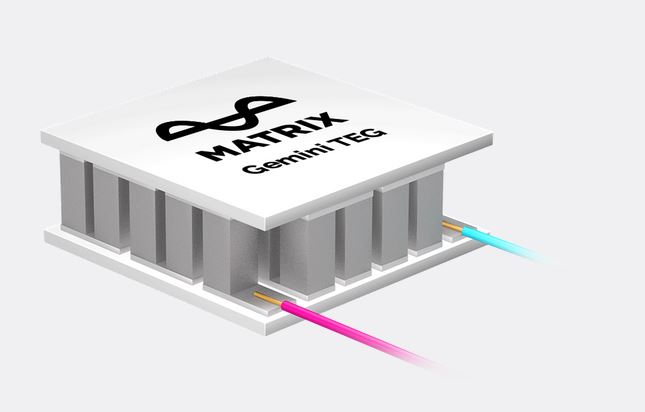

The basic component of a thermoelectric device comprises a single structure of type-P and type-N semiconductor thermoelectric material, each electrically connected in series. The Matrix Gemini Thermoelectric Generator (TEG) is a high-performance energy harvesting device, specifically designed to maximize the conversion from low-temperature heat sources into electricity. It features a stable, high-performing thermoelectric material with 30% more efficiency than conventional thermoelectric materials (Figs. 1 and 2 ).

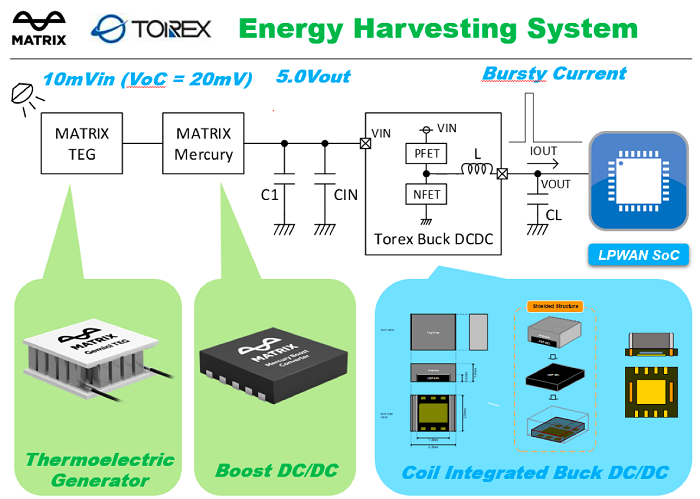

Fig. 1: A circuit diagram with thermoelectric energy harvesting. Matrix’s Mercury IC is a Nanopower energy harvesting synchronous boost converter with a microwatt cold-start, input impedance matching, and regulated out.

Fig. 2: The MATRIX TEG for energy harvesting.

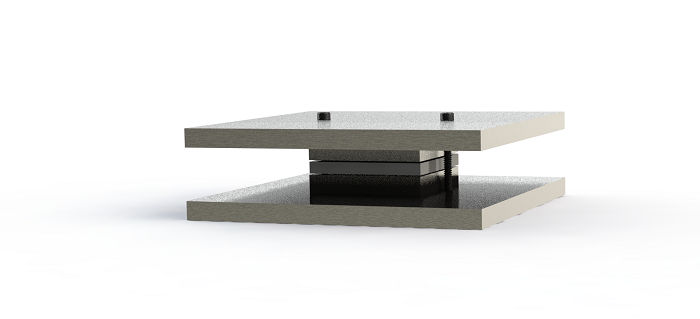

The Matrix PowerTile is an example of a thermoelectric-based power source that harvests electricity from minimal temperature variations of about 2°C. It can be buried underground or embedded into building infrastructures, generating everlasting power for IoT nodes. (Fig. 3 ).

Fig. 3: Layout of the MATRIX TEG.

“Thermoelectric engineering bears the tremendous potential to disrupt the energy source for IoT. It enables power harvesting from thin air through temperature fluctuations. Each thermoelectric system can be customized to various shapes and sizes to accommodate the power needs and design of the end product,” said Meng He, Matrix’s vice president of product. “Ultimately, the evolution of thermoelectric [engineering] allows IoT nodes to be deployed to places that were once impossible to approach, unleashing unlimited possibilities.”

The new frontier without a battery

Atmosic and Matrix will collaborate with key customers of industrial and consumer devices to implement connected solutions powered by thermoelectric techniques, and other energy harvesting techniques for a new level of efficiency and productivity.

“Atmosic and Matrix are committed to reducing the industry’s reliance on batteries to power IoT devices,” said Atmosic’s CEO David Su. “Atmosic’s innovative lowest power connectivity solutions, combined with Matrix’s cutting-edge thermoelectric technology, will enable customers to significantly reduce or even eliminate the use of electrical/wired or battery power in a variety of applications and enjoy cost savings as a result.”

Reducing the use of wired, electric, and battery-powered energy in IoT applications offers a number of economic and environmental benefits. Unlike many devices that require frequent battery replacement, low-consumption IoT solutions with energy collection have a significantly longer battery life or can be completely battery-free, simplifying maintenance operations and reducing maintenance costs.

In a few years, it is estimated that there will be over 35 billion connected devices worldwide. Atmosic and Matrix technologies are well-suited for a wide range of industrial applications for agriculture, along with consumer devices such as wearable devices and home automation products where access is significantly critical. The collaboration allows Atmosic to extend its reach and useful market available in untapped IIoT segments, as well as to expand its presence in the consumer devices segment. In turn, Atmosic's wireless technology enables Matrix to offer full-service solutions with ultra-low-power connectivity to the IoT.

“The key to energy harvesting for connected IoT devices is its baseline power consumption. Atmosic has designed an extremely low power – five to ten times lower than average – Bluetooth solution that is standards compatible. As a result, small amounts of harvested energy enables battery-free or forever battery devices,” explained Srinivas Pattamatta, Atmosic’s vice president of business development. “By designing a comprehensive power management controller inside the Bluetooth SoC, multiple energy harvesting techniques can be used concurrently, assuring constantly powered, long lasting forever connected solutions.”

The photoelectric, thermoelectric, piezoelectric, and electrodynamic techniques are well known and are often used to power the wireless sensor network (WSN) detection nodes, which transmit the data to a central controller. Energy harvesting technologies can be used to improve the reliability and availability of industrial systems.

Powering a wireless sensor node from an environmental or “free” energy source is interesting because it can eliminate the need for batteries or cables, offering an obvious advantage when replacing or maintaining the battery is difficult, expensive, and requires considerable labor.

Advertisement

Learn more about Electronic Products Magazine