By Gina Roos, editor-in-chief

Electrical engineers at Duke University announced that they have developed a fully print-in-place technique for electronics that can work on sensitive surfaces such as human skin and paper. The new technique could advance medical devices printed on materials such as skin or bandages that include biosensors and embedded electronic tattoos.

“For direct or additive printing to ever really be useful, you’re going to need to be able to print the entirety of whatever you’re printing in one step,” said Aaron Franklin , the James L. and Elizabeth M. Vincent Associate Professor of Electrical and Computer Engineering at Duke, in a press release. “Some of the more exotic applications include intimately connected electronic tattoos that could be used for biological tagging or unique detection mechanisms, rapid prototyping for on-the-fly custom electronics, and paper-based diagnostics that could be integrated readily into customized bandages.”

Researchers described the processes in two recent papers. The Nanoscale article highlights how the room-temperature printing of conductive traces advance the direct writing of electronic tattoos and other devices onto biological tissues, such as human skin. The primary challenge, say researchers, has been the use of conductive inks that require biologically harmful post-processing techniques to attain the required electrical performance, along with the degradation of printed conductive traces during bending stresses.

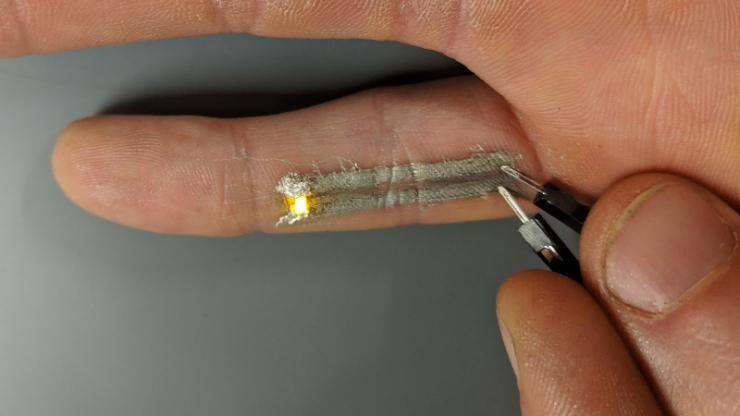

The work conducted by Franklin’s lab and the laboratory of Benjamin Wiley, professor of chemistry at Duke, shows that the use of water-based inks that consist of silver nanowires enable the printing of conductive traces at low temps, and eliminate the harmful post-processing techniques. In addition, the traces retained their high electrical performance, even under up to 50% bending strain and cyclic bending strain over a thousand bending cycles. The researchers used an aerosol printer to print the ink onto substrates such as an apple and human finger, which dried in less than two minutes, a key requirement for direct writing of electronics on sensitive surfaces.

“Nobody thought the aerosolized ink, especially for boron nitride, would deliver the properties needed to make functional electronics without being baked for at least an hour and a half,” stated Franklin. “But not only did we get it to work, we showed that baking it for two hours after printing doesn’t improve its performance. It was as good as it could get just using our fully print-in-place process.”

(Image: Duke University)

A video accompanying the paper shows the printing of two electronically active leads along the underside of a finger.

The ACS NANO article details how the researchers solved the challenges of implementing low-temperature printed devices using semiconducting carbon nanotubes (CNTs) printed into thin films that offer high electrical performance, mechanical stability, and low-temperature processing. In this paper, Franklin and graduate student Shiheng Lu combine the conductive ink with two other printable components to create functional transistors.

The researchers said they were able to demonstrate 1D–2D thin-film transistors (1D–2D TFTs) in a low-temperature (maximum exposure ≤80 °C) full print-in-place process (This means no substrate removal from the printer throughout the entire process.) using an aerosol jet printer. The key takeaways are that Franklin’s print-in-place technique doesn’t require the substrate to be removed for additional processing, and can be completed at the lowest overall processing temperature.

“Over the years there have been a slew of research papers promising these kinds of ‘fully printed electronics,’ but the reality is that the process actually involves taking the sample out multiple times to bake it, wash it or spin-coat materials onto it,” Franklin stated. “Ours is the first where the reality matches the public perception.”

However, Franklin noted that his printing method won’t likely replace large-scale manufacturing processes for wearable electronics. Instead, he sees potential in rapid prototyping or applications where “one size doesn’t fit all.”

Advertisement

Learn more about Electronic Products Magazine