By Gina Roos, editor-in-chief

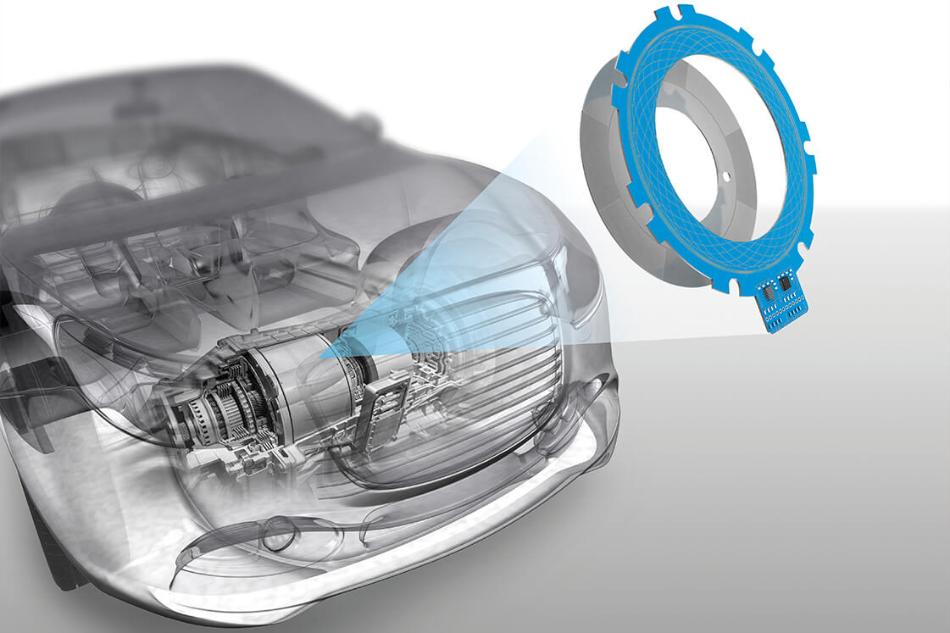

ams claims the industry’s first inductive position sensor, available as a standard product, for high-speed, automotive, and industrial electric motors. The AS5715 sensor offers size, weight, and cost savings compared to resolvers used in vehicles today, said the company.

The AS5715 inductive sensor is highly configurable and can be used in on-axis (end-of-shaft) and off-axis (through-shaft or side-of-shaft) topologies and with many types of multi-pole-pair motors.

New rotor position-sensing solutions based on the AS5715 can match the accuracy and latency of resolvers widely used in high-speed motor applications, said ams, and provide savings in bill-of-materials (BOM) cost, size and weight. The AS5715, based on an ASIL-C implementation, is also ISO 26262 functional safety standard-compliant.

A big target market for the AS5715 is automotive electrification. “The commercialization by ams of inductive position sensor semiconductor technology marks an important advance in the drive to electrify automotive systems such as power steering, as well as the traction systems in electric and hybrid electric vehicles,” said the company.

A couple of automotive trends driving the need for improved position measurements include the transition to permanent magnet synchronous motors (PMSM) from brushless DC motors in many high-speed applications and tighter global government regulations to cut average fuel consumption. “By replacing legacy electromechanical and hydraulic automotive systems with efficient electronically controlled motors, car manufacturers can reach their fuel consumption targets more quickly,” said ams.

Thanks to highly accurate, low-latency position measurements produced by the AS5715, the sensor IC can enable high-speed motors to maximize torque, limit torque ripple, and achieve high efficiency. A position sensor system based on an AS5715 IC and its associated coil printed on a low-cost PCB can achieve accuracy up to ±0.3° at rotation speeds up to 100,000 rpm in various motor types, including four-pole-pair PMSMs, according to the company.

The AS5715 is available for sampling now. An evaluation kit is available on request from ams. The company also offers documentation and application guides for designing Tx and Rx coils in the static sensor PCB and the rotating target assembly affixed to the rotor. A fully redundant measurement system can be implemented by mounting two AS5715 ICs on the sensor board.

Advertisement

Learn more about Electronic Products Magazine