By Gina Roos, editor-in-chief

Startup Rohinni teamed up with Beijing-based display giant BOE to develop LCD displays and video walls. The new joint venture, BOE Pixey, in the works since 2017, leverages Rohinni’s miniLED and microLED technology and BOE’s leadership in the display market to bring micron-scale LEDs to mass market. This is the Coeur d’Alene, Idaho-based company’s third joint venture in three years.

BOE Pixey will focus on designing and building LCD display backlights, direct-emission displays, and display-related sensors for high-performance televisions, video walls, and other large-format end products. The joint venture will integrate Rohinni’s high-speed and high-accuracy miniLED and microLED manufacturing process with BOE’s design, development, and manufacturing capabilities to create ultra-thin, high-performance displays.

MiniLED-based LCD designs can deliver 1,500 nits peak brightness, 10,000+ local dimming zones, a contrast ratio of >1,000,000:1, and 8K HDR. (Image: Rohinni)

The joint venture has operations in Beijing and Hefei, China. It already has a high-speed line in operation today in Beijing that is building samples. Plans are underway to add several lines in Hefei throughout 2020.

Direct-emission displays, including video walls, are made by precisely placing hundreds of thousands of miniLEDs or microLEDs directly on a substrate using BOE Pixey’s approach, and offer a significantly better viewing experience than currently available video walls built from packaged LEDs, said Rohinni’s CEO Matthew Gerber.

MiniLEDs and microLEDs haven’t been commercialized for these kinds of products because making them in high volumes wasn’t possible,” he added.

But this changed with the development of Rohinni’s miniLED and microLED manufacturing process that enables high-speed and high-accuracy die placement. The company has more than 90 patents either granted or in progress for its direct-transfer placement process and related production processes as well as products such as displays, keyboards, logos, and diffusers.

A key differentiator of the process, besides the speed and accuracy, is the ability to bin wafers in real time and place the LEDs directly on the substrate. Rohinni’s process could be a game changer in the LED manufacturing supply chain by changing the way LEDs are currently supplied. Typically, LED manufacturers supply packaged LEDs that are “binned” or sorted by color and brightness. Then the individual bins are sold to customers based on their application requirements.

With Rohinni’s placement process, LED manufacturers can supply the wafer with a map that shows where the different bins can be pulled from the wafer. Rohinni can then program its machines to take die from, as an example, five bins for a particular substrate.

It obviously eliminates a step in the supply chain, said Gerber. But from a design standpoint it gives designers the ability to select how tightly they want to manage a bin range for more consistency in the light output, he added.

Gerber believes the company has been successful because it took a holistic approach to the process. It looked upstream from its placement process, and downstream at how it manages the supply chain and post-processing processes. This includes how it handles defects, testing, and rework.

The road to commercialization

The kernel of an idea that started Rohinni’s journey nine years ago began when the company’s founders first saw microLEDs. If they could find a way to commercialize a high speed and highly accurate way of placing those devices then they could invent or facilitate the invention of a new generation of products. The company, launched in 2013, has spent the last six years “figuring out ways to develop the processes to take these small packaged devices and place them on circuits,” said Rohinni’s CEO Matthew Gerber.

The result was a placement process that can be applied to any unpackaged semiconductor, including LEDs, sensors, and controllers. Initially focusing on LEDs, centered around miniLEDs and microLEDs, the company’s vision is “to make impossible products possible” thanks to its ability to execute micro-scale electronics.

“Usually 80 percent to 90 percent of LEDs are packaged, so we give the designer the ability to remove the package and place the device directly,” said Gerber. “In doing so, it lets a designer create products that are actually brighter, significantly thinner, and in a lot of cases and applications, because you can put a lot more LEDs in a small space and drive them much more efficiently, the entire device is much more power efficient.”

An additional benefit that designers like, thanks to packing a lot more LEDs together, is the ability to create products that look like they are animated. The animation and motion capabilities enable designers to build differentiated product designs.

“A big difference [compared to current technology] is we can place a lot more LEDs because they’re unpackaged, and we place them a lot closer together, so you don’t need anywhere near the thickness to diffuse the light and the diffusion layers are completely different so you get a much thinner product,” Gerber said.

“From a brightness standpoint because we have so many more LEDs in the backlight layer, we can achieve four to five times brighter displays than existing high-end TVs,” he continued. “And depending on how many LEDs are in the backlight, we can get significantly better or similar orders of magnitude improvements in contrast ratios.

In 2016, Rohinni made one of its first key strategic decisions about how to go to market and commercialize its miniLED and microLED technology. It could have chosen a traditional strategy of licensing its technology to pick-and-place equipment manufacturers or build the products itself, which would have required the company to raise several hundred million dollars of capital. Instead, the startup decided to take the joint venture route where it would collaborate with partners with a lot of industry muscle.

The company formed its first joint venture, Luumii, in 2016 with Taiwanese-based KoJa, a leading manufacturer of computer keyboard membrane switches. The joint venture is focused on keyboard backlighting and logos for notebooks. Headquartered in Taipei, Taiwan, Luumii’s manufacturing facility is in Suzhou, China.

The second joint venture, Magna Rohinni Automotive, was formed in 2018 with automotive leader Magma to bring Rohinni’s microLED lighting solutions to automakers and the mobility market. Magna also made a minority equity investment in Rohinni. Magna’s electronics manufacturing facility in Grand Blanc Township, Michigan, also serves as the home to the joint venture.

The third joint venture, BOE Pixey, in partnership with China-based BOE, was announced in December 2019. Based in China, this joint venture focuses on building LCD display backlights, direct-emission displays, and high-performance televisions, video walls, and other large-format end products.

So, the question is does the company have the bandwidth to form more joint ventures?

“You hit on the core strategic decision that’s in front of us in about six to nine months after we get this BOE joint venture up and running. We probably have room to do another two or three over the next few years,” said Gerber.

The next logical areas are general lighting or semiconductor packaging, he said.

Technology benefits

For LCD TV displays and video walls, benefits fall into three categories – manufacturing production, picture quality, and functionality. Benefits range from reducing production time and improving yields to achieving a better picture quality, enabling larger size modules, and opening up new features and functionality such as embedded sensors.

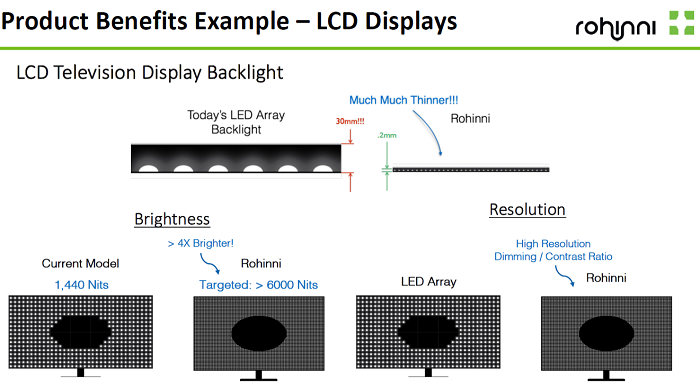

Gerber said LCDs using miniLED backlights outperform other LCD technologies in a range of parameters, including thickness, contrast ratio, brightness, and consistency.

As an example, a high-end 75-inch TV with an array backlight, consisting of 600 or 800 LEDs with projector beam diffusers that have a super-thick assembly up to 30 millimeters, said Gerber. In comparison, a Rohinni-based backlight could be as thin as 200 microns, he added.

LCD TV display backlights using Rohinni’s technology can achieve a much thinner, brighter, and higher resolution and contrast ratio. (Image: Rohinni)

Greater functionality is another added benefit. The Rohinni process allows companies to use unpackaged semiconductors, beyond just LEDs, which means a lot more functionality can be built into the video wall.

“I think the coolest aspect of the benefits is the ability to distribute things like sensors, transmitters, and receivers in the video wall,” Gerber said. “Imagine a video wall that has enough sensor capability where you don’t need an augmented reality or virtual reality headset to interact with that wall. Instead you can interact with that wall directly by standing right in front of it.”

The new company expects consumer devices using the BOE Pixey miniLED and microLED-based displays to be available in the second half of 2020. Rohinni will demo its high-performance display products at the Consumer Electronics Show (CES) in January 2020.

Next steps

As BOE Pixey ramps up its production capabilities, Rohinni will continue to develop faster miniLED placement processes, new substrate materials, and new form factors.

“As a company, we are not going to stand still. Our end of the partnership with this joint venture [BOE Pixey] is to continue to deliver improvements to our existing process,” said Gerber. “We want to get speeds faster and move to larger form factors.”

“Because BOE Pixey will be a standalone company we also want to make sure that we enable the joint venture to create and protect its own IP,” he added.

The company also is developing smaller sized microLEDs in its labs, which will allow the company to build smaller direct emissions displays. “ The goal is to move out of the lab and into commercial operation in 2020,” said Gerber.

This article was originally published at sister publication EE Times.

Advertisement

Learn more about Electronic Products Magazine