By Maurizio Di Paolo Emilio, editor-in-chief, Power Electronics News

Editor’s note: My AspenCore colleague Maurizio Di Paolo Emilio shares how he and other engineers are working and collaborating remotely with other team members.

Enabling telecommuting means digitizing all business processes so that information is immediately available to all those involved in a given task. Easier said than done, though, for employees working in engineering. It takes a lot of creativity to set up an experimental laboratory.

Telecommuting is common enough in some countries but a relatively new concept in many others. Employers who allow it tend to merely tolerate it, but given today’s circumstances, more and more organizations are actively encouraging employees to work and collaborate remotely. Some companies — most of them in Europe — have taken to calling this “smart working.”

Engineers who are private contractors (or who are otherwise freelancing) are experts in working remotely. They’ve had to reinvent their working approach and meet the needs of as many customers as possible. They’ve had to figure out remote network configurations for development tools for MCUs and FPGAs, simulation, debugging tools, main prototyping, and testing equipment.

Maurizio’s laboratory in Italy with the main laboratory instruments, except laptops and a whole series of monitors (Image: Maurizio Di Paolo Emilio)

In this article, I’ll offer the telecommuting experiences of many technicians from some of the most significant international companies. I will also illustrate how we, the engineers, adapt and manage to work in the era of the COVID-19 pandemic. Everyone is welcome to comment with pointers of their own. As we are planning on another photo essay on this topic (“This Is Where We Work”), please send me via email () pictures of your workbench at home, sharing highlights of your arrangements.

Organization

For those who never experienced remote working, it can be challenging. One of the keys to working successfully from home is to have a quiet, dedicated place, free from distractions, which is perhaps a little complicated when we have a lot of things happening around us at home. Of course, you might end up with the opposite problem: sitting in front of the computer for hours and forgetting to get up for a break.

“The key to working from home is to find the right balance between these two extremes: working 24/7 and taking much-needed sanity breaks,” said Thomas Fowler, vice president of engineering, Silicon Labs.

The most important tool is the computer, but you’ll also need programming tools and spreadsheets. You need a monitor (or two), an extra power cord, a mouse, a docking station, and an excellent set of earphones or headphones with an efficient microphone. Having an excellent videoconferencing system is essential for large-scale collaboration.

“Choosing the right messaging platform also provides significant benefits, including the ability to share timely one-way broadcasts and to engage in general chats on active topics,” said Fowler. “Finally, one must have a high-quality, high-speed internet connection. Without it, the rest falls apart.”

![]()

The home office of an unidentified Silicon Labs engineer. The silver box with the blue cable is a portable GT tester. Devised for internal use, company engineers can take it home and use it to test the company’s ICs. (Image: Silicon Labs)

He continued, “The biggest challenge to leaving the engineers at home is the reduction of collaboration. There are certainly ways to improve collaboration through the right virtual communication platforms, but sometimes, being able to engage directly with another nearby designer and ask, ‘What do you think about this?’ can make the difference between spending an hour or a day to resolve a challenging issue.”

“Not only technicians but also project managers have to change their mindset in order to improve communication and tasks assigned,” said Davide Di Gesualdo, embedded software engineer and technical writer at EEWeb. “PMs must know their collaborators’ skills and personality very well to be able to use them for the proper task and approach them in the best way.”

“As a smaller company, we are able to be responsive and nimble in these difficult times,” said Chris Dries, CEO of UnitedSiC. “When it comes to our engineering teams, we are fortunate to already have strong home-working practices in place. Many of our engineers are set up with home labs, meaning they can work remotely alongside a number of the senior team. This means that telecommuting is central to our working practices with teams communicating and collaborating using connecting tools like Microsoft Teams, Basecamp, and GoToMeeting. We’ve had this set up from the beginning, as we consider it vital to have the best talent on board. In 2020, we simply don’t believe that geography should be a barrier to innovation. It just so happens that this means we are well-placed to weather this particular storm and maintain our current level of development.”

Hardware and software

Electronic engineers should have the maximum amount of tools available to continue with firmware and hardware development. Firmware developers must have access to software platforms to continue with programming; hardware developers will need to organize themselves, as far as possible, with laboratory equipment in order to be able to conduct significant verification tests where required. Organize remotely with the company where possible.

“It is important to remember that much of engineering is a collaborative creative process,” said Shelley Gretlein, vice president of global marketing at National Instruments. “Troubleshooting, talking through bugs or problems, and regular brainstorming are all vital parts of every engineer’s work. Fortunately, this can now be easily accomplished online.” Of course, software test systems are incredibly valuable for engineers working remotely. Unlike the instrument lab, these systems remove any physical barriers to collaboration throughout the team and the testing process.

“In these unprecedented times, we are working to support our customers by allowing access to NI work licenses from home, so engineers can carry everything they need to work effectively from their laptops,” said Gretlein.

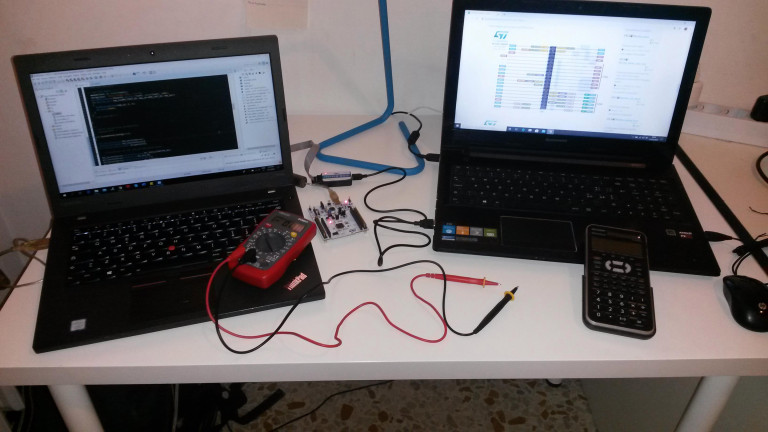

Nicolas Fillon’s laboratory table (Image: Nicolas Fillon)

The design and prototyping processes are characterized by a complex sequence of PCBs, assemblies, firmware development, and testing. The distribution of people can slow the process down, making it more complicated. The important thing is to be able to organize yourself to cope with any situation.

Every engineer, maker, or “geek” with electronics must necessarily have a small laboratory at home to have fun. During my career, I have had the opportunity to work with different companies in the electronics field. All this allowed me, in time, to build a small test and measurement laboratory. You can never miss a development kit like Arduino and similar, a whole series of shields for experimenting and testing. But very important will be the software tools for software and hardware design.

Many of my electronics friends have all the fundamental components, resistors, capacitors, LEDs, small power supplies, and DC-to-DC converters available in their small laboratories — all fundamental to experiment with electronics.

Nicolas Fillon, field application engineer at ST Microelectronics, said, “Please see what my setup looks like these days. I covered all the bases so far and I can do everything I was able to do in the lab — so no issues so far — but this is only the beginning; let’s see how it goes. Here, you can see laptop, internet access, second screen if possible, eval boards, USB cables, jumpers, soldering station, scope, multimeter, bus analyzer, tools like screwdrivers, a few docs. For software, instead, IDEs such as IAR, Keil, STM32CubeIDE, compilers such as C Cosmic, STM32CubeProgrammer, and Github.”

An electronics engineering project usually consists of three parts: schematic and simulation, prototype debugging and firmware development; construction; and testing. The simulation of the circuit can be performed, with excellent results, all while operating remotely. “For the testing and construction phase, I don’t think there’s anything we can do but go to the factory,” said Fillon.

“The first (schematic) one is easily remote-able when you have a couple of big monitors and a big spare table to fit them,” said Fabio Violante, CEO of Arduino. “The second one is the most difficult when working from home, as you usually need a good soldering station and oscilloscopes (and spare parts). For firmware development, since the board is usually more or less working, you can replace the oscilloscope with a portable USB logic analyzer. Most tools, like debuggers, are already very portable and cheap. Working with connectivity, particularly Ethernet, can be troublesome in a home environment, but some long cables can help.”

VPN connection

In the case of a hardware designer or firmware developer, telecommuting is considerably simplified. “Those who play such a role are usually provided with a portable PC, supplied by the company, with sufficient performance to run the software applications required for the design activity in a fluid way,” said Stefano Lovati, technical writer at EEWeb. “For security reasons, most companies make a secure VPN connection available to the smart worker, which can be used to access centralized project files or to run applications installed on corporate servers. Many development tools, however, only require a fast internet connection (the costs of which, depending on the type of contract, may be covered by the company) and possibly a license, provided by the same organization.”

Stefano Lovati’s home lab (Image: Stefano Lovati)

“The vast majority of our developers are working from home,” said an Infineon spokesperson. “They have access to the company network through VPN and can, for instance, connect remotely to the company’s centralized UNIX compute farms. This way, they have access to all the necessary tools and resources. For those developers/ designers that have to work on the Infineon premises — be it for security reasons or for hardware testing — specific health security measures are applied. These mainly aim at distancing people from each other.

“For instance, people work in time shifts in order to avoid face-to-face contact,” they continued. “With the situation being highly dynamic, adjustments are made as necessary. Employees certainly have to adjust to the virtual forms of collaboration instead of personal exchange. Skype works well on a verbal level. Designers who were, for instance, used to discussing a concept idea on the physical whiteboard now need to do this virtually. Moving to the virtual plane dimension is not so trivial for most of us. Teams are getting creative, for instance, with going for a virtual coffee-talk every morning.”

Simulation

“Another thing concerning schematics is the simulation,” said Dave Wilson, NI’s Business and Technology Fellow for Portfolio Business. “This is another huge point in software; a lot of things can be simulated. We make a product called Multisim. Simulation tools to support schematic capture and algorithm runs are a vital piece of the puzzle. Multisim is a good example of this and is available online for free. But what about their power supplies? Do they have access to a multimeter? And how likely is it that they will have their own oscilloscope? All-in-one instrumentation suites such as the VirtualBench can be a cost-effective solution to fully equip the home lab.”

Jonathan Dodge from UnitedSiC in his home office (Image: UnitedSiC)

Software developers tend to transition to working at home more efficiently because they don’t need extra equipment to perform their tasks — just a good workstation/monitor and proper audio-video equipment for videoconferencing.

Some difficulties may arise at the FPGA firmware development level, however. Even if you have a high-performance machine, the synthesis of an FPGA can take several hours of processing. “However, the greatest difficulties are encountered during hardware and firmware integration,” noted Stefano Lovati. “Which necessarily requires the availability of advanced test equipment (multi-channel wideband oscilloscopes, spectrum analyzers, logic state analyzers, etc.) and the simultaneous availability of multiple designers to investigate potential issues. It follows that integration and validation are normally carried out in full-equipped labs, compliant with the applicable safety standards.”

Wilson said, “Historically, we’ve also been shrinking systems to make them more portable. The CompactRIO device, for example, offers a huge variety of high performance I/O, real-time, FPGA — meaning you can take this home and run a full engine simulation (combustion, EV, or otherwise).”

Hardware development

The hardware developer, on the other hand, sees his tasks as slightly complicated. Here comes into play the flexibility of the company to provide the best resources for the worker or to move them where necessary to their own home. “As far as HW development, the situation has been slightly more complicated to handle because working on physical hardware often requires lab instruments,” said Violante. “Fortunately, we were able to reach a compromise situation by moving some of our portable office equipment to the engineers’ houses.”

Fabio Violante’s home office (Image: Fabio Violante)

He added, “We already have a quite distributed workforce, but we took extraordinary measures to ensure the safety of our workers. Basically, everyone is working from home, from administration to engineering. We are gradually upgrading the equipment, too.”

The complexity of electronic tools has grown over time. For most devices such as MCUs and FPGAs, almost exclusively the development environments and compilers provided by the respective manufacturers are used. However, there are some great open-source projects suitable for hardware and firmware design.

“For PCB layout and schematics design, we can mention KiCAD, EasyEDA, and Autodesk Eagle (some of these have restrictions in the free version),” Lovati said. “For circuit simulation, both analogical and digital, there are numerous open-source tools, including: SPICE and related variants (such as LTspice), Oregano, Electric VLSI Design System, Gnucap, Micro-Cap, Logisim and more. Regarding software and firmware toolchains, the primacy certainly belongs to the GNU Compiler Collection (GCC), integrated in numerous compilers provided by third parties.”

Application engineers often require access to the various hardware configurations that users have problems with, and this is very difficult to achieve generally because our users create all sorts of very different combinations of hardware components, Violante explained.

“We usually try to have at least one unit of each product available to replicate issues, but often, we need to perform complex measurements or even rework the boards a bit to access signals or to test edge cases, and of course, this becomes particularly difficult to do remotely unless you have some sort of home laboratory with all the required spare parts that may be needed,” he said.

“We’ve got something called Virtual bench, which consolidates all that instrumentation into a slightly bigger box, which is smaller than a shoebox,” said Wilson.

An initial hardware design can, however, be performed remotely. If the requirements of the application have been defined in detail, as well as the electrical characteristics of the signals that define the communication interfaces with the outside world, the electronic designer can proceed with the definition of the PCB scheme and layout. When the first prototypes of the board are available, a hardware debugging phase is required. It is preferable to carry out this step in laboratories, where, in addition to test equipment, electronic microscopes and professional soldering stations are also available. In exceptional cases, you can prepare your own home laboratory to cope with any possible situation.

“For production customers, in particular, there are some instances where hardware needs to be physically rebooted,” said Wilson. “However, by stripping back the number of staff physically on-site through remote access to code and with monitoring systems including SystemLink, RF, or STS, the factory floor is made markedly safer for critical staff.”

Integration

Integration, however, must take many factors into account. “Integration must necessarily be carried out in the lab,” said Lovati. “It should also be kept in mind that several issues, especially those related to timing, can only be encountered at this stage. Although many development tools are able to estimate the executing times of the algorithms running on an FPGA, only the hardware/firmware integration will be able to tell us how long it takes to boot the device or perform certain operations.”

Moreover, “complex systems using actuators (such as heavy electric motors or pumps or electrovalves) and expansive sensors have to be integrated with the electronic board, so this task has to be often carried out in the laboratory, too,” said Di Gesualdo.

Davide Di Gesualdo was still in the process of setting up a remote work station for a project. (Image: Davide Di Gesualdo)

Some engineers may have some basic test equipment at home. Or they may have a debugging kit or an evaluation kit that can be used for some analysis, but the reality is that the capacity is very limited.

“In an attempt to address this challenge, we are trying to use a collaborative method,” said Fowler. “We may have only one or two people at a time in a lab to adhere to social distancing, and they become the eyes, ears, and hands of other engineers who are working remotely. Those in the lab can perform the test setups, changeovers, maintenance, and more. When the correct parts and systems are ready, an apps engineer or test engineer can typically run a remote session where they can actuate the tests and see results. Without this collaborative mode of operation, it would be difficult to accomplish serious engineering work. It’s essential to have at least a skeleton crew available in the lab to move the design and test process forward.”

Conclusion

Telecommuting can easily lead to isolation without a team to phyisically collaborate with. But there are many ways to improve collaboration and always be active with the right online communication platforms, like Skype or other videoconferencing platforms. In addition to creating your own work environment, for an engineer, it means: oscilloscope, spectrum analyzer, computer, development kit, and — for an even more practical engineer — wires, cables, and connectors. It’s essential to have the right team (online) that can make a difference and keep a healthy and positive mentality in particular moments like the one we are experiencing.

“Maybe this particular situation can be the catalyst for smart working, even for the most reluctant companies: a new way of working that’s more convenient for everyone,” said Di Gesualdo.

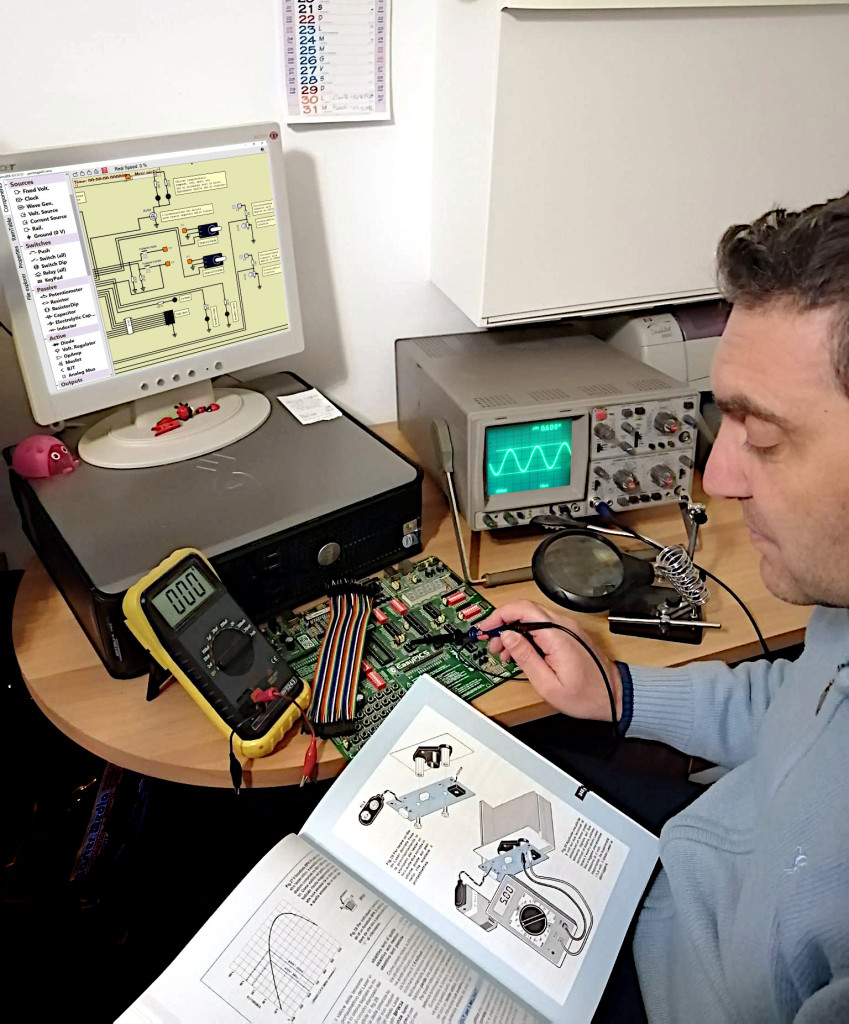

“In this period of social crisis, smart working is a way of salvation for companies that work online,” said Giovanni Di Maria, technical writer at EEWeb and electronic designer. “With this type of activity, personally, my working hours have significantly increased. Teaching-learning has increased. But electronic experimentation continues, probably has increased. The suppliers still deliver electrical material and, in any case, my laboratory is very well-equipped with electronic components. Smart working is undoubtedly a great advantage for everyone. In any case, it is hoped that the COVID-19 problem will soon be over in order to recover the old personal contacts and social relationships.”

Giovanni Di Maria at his lab table (Image: Giovanni Di Maria)

Special thanks go to: Fabio Violante, the Infineon team, Thomas Fowler, Dave Wilson, Shelley Gretlein, Chris Dries and Jonathan Dodge, Nicolas Fillon, Stefano Lovati, Davide Di Gesualdo, and Giovanni Di Maria.

This article was originally published at sister publication EE Times.

Advertisement

Learn more about Electronic Products Magazine