By Bonnie Baker, Maxim Integrated

Portable instruments, handheld consumer electronics, and low-power industrial and medical equipment usually require a battery to operate. Whether the instruments include or do not include an installed battery, the customer must connect or install the battery before operation.

Having to deal with battery installation is annoying for most end customers who expect a quick startup experience (Fig. 1 ). The most convenient configuration is to have the battery pre-installed as the equipment waits on the shelf for sale. However, an extended shelf time compromises an electronics’ battery life, as it slowly leaks battery charge in standby mode.

An additional drain on the battery during regular operation occurs when the equipment is in standby mode while waiting for the next command. The battery drain occurs during operation when the equipment’s integrated circuits (ICs) are in a low-current standby state, with the IC standby currents as high as tens of milliamperes. These ICs will continue to place a drain on the battery over time, causing a dead-battery annoyance.

This article will briefly discuss a simple approach that maximizes battery life for multiple applications by powering down the majority of equipment ICs during operation with an on/off electrical or mechanical switch.

Building the instrument

Each battery-powered equipment has its own set of design requirements. Still, to operate in a powered environment, an IC’s current consumption is at the top of the list.

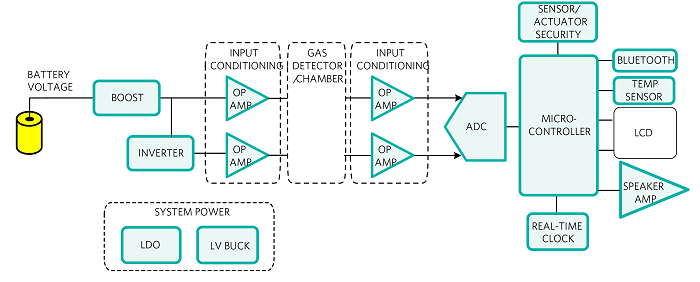

For instance, a battery-powered gas sensor that measures CO2 gas and sends the measurement results to the LCD and/or alarm requires multiple ultra-low-current devices with shutdown capability (Fig. 2 ).

Fig. 2: A block diagram of a battery-powered industrial gas meter

In Fig. 2 , the industrial gas meter’s ICs include power converters, several operational amplifiers, a delta-sigma (ƩΔ) analog-to-digital converter (ADC), a microcontroller (MCU), a real-time clock (RTC), and various output devices that display and transmit the gas detector’s data. The MCU algorithm in Fig. 2 keeps devices in their shutdown mode with occasional data acquisition and transmission activities (Fig. 3 ).

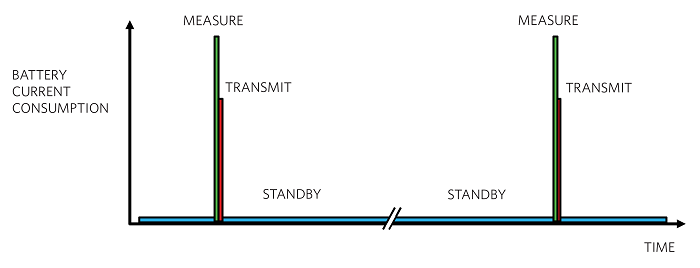

Fig. 3: This timing diagram illustrates the gas sensor’s current consumption relationship between standby mode and the measured and transmitted activities.

Although it appears in Fig. 3 that the current consumption in standby mode sufficiently preserves battery life, the standby current drain significantly impacts the total battery life picture. The ICs in the portable gas equipment (Fig. 2 ) can have a typical standby current of tens of milliamperes.

Further power reduction

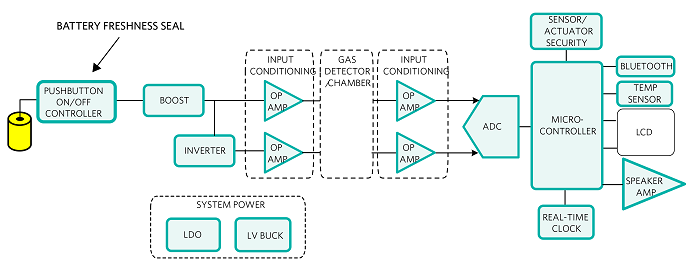

An alternative solution uses a nanoPower pushbutton on/off controller with a battery freshness seal capability (Fig. 4 ).

Fig. 4. The pushbutton on/off controller removes the battery power from the remainder of the circuit.

In Fig. 4 , the addition of a pushbutton on/off controller provides a way to enable the overall off-the-shelf battery freshness goal by a 1,000× reduction of the total shutdown battery drain. The equipment’s delta standby current range changes from tens of milliamperes to tens of nanoamperes.

The pushbutton on/off controller is an integral part of the battery-powered gas sensor’s low-power algorithm by only leaving the pushbutton on/off controller and boost converter in their standby modes. The on/off controller completely disconnects the remainder of the circuit from the battery. In this manner, the on/off controller creates a “freshness seal” for the battery (Fig. 5 ).

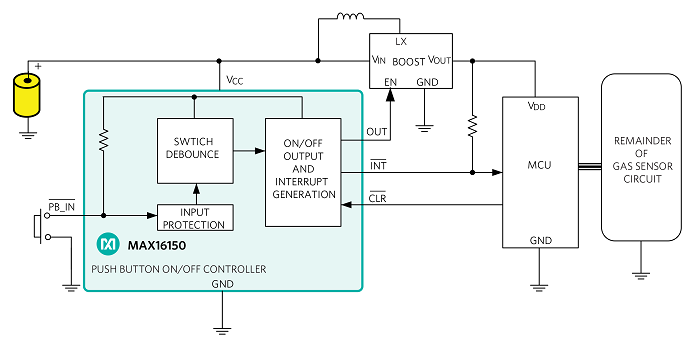

Fig. 5. The nanoPower pushbutton on/off controller disconnects the battery from most of the gas sensor system.

The nanoPower pushbutton on/off controller in Fig. 5 has a switch debouncer and built-in latch. This device accepts a noisy input from a mechanical switch and produces a clean, latched output as well as a one-shot interrupt output in response to a switch closure that exceeds the debounce period at PB_IN.

The nanoPower pushbutton on/off controller extends battery life shelf time and operating standby time with its ultra-low 20-nA standby current.

Conclusion

For a battery-powered, out-of-the-box device to operate immediately, a nanoPower pushbutton on/off controller provides a battery freshness seal and gets rid of the end customer’s initial battery installation. The satisfaction gained from this quick, off-the-shelf startup experience is further enhanced with extended battery life during operation.

Bonnie Baker is a principal writer at Maxim Integrated. She is a seasoned analog, mixed-signal, and signal chain professional and electronics engineer. Baker has published and authored hundreds of technical articles in industry publications. She is also the author of “A Baker’s Dozen: Real Analog Solutions for Digital Designers,” as well as co-author of several other books. In past roles, she worked as a modeling, strategic marketing, IC architect, and designer engineer. Baker has a master’s degree in electrical engineering from University of Arizona (Tucson, Arizona) and a bachelor’s degree in music education from Northern Arizona University (Flagstaff, Arizona). She has also planned, written, and presented hotel and online courses on engineering topics, including ADC, DAC, operational amplifier, instrumentation amplifier, SPICE, and IBIS modeling.

Advertisement

Learn more about Electronic Products MagazineMaxim Integrated