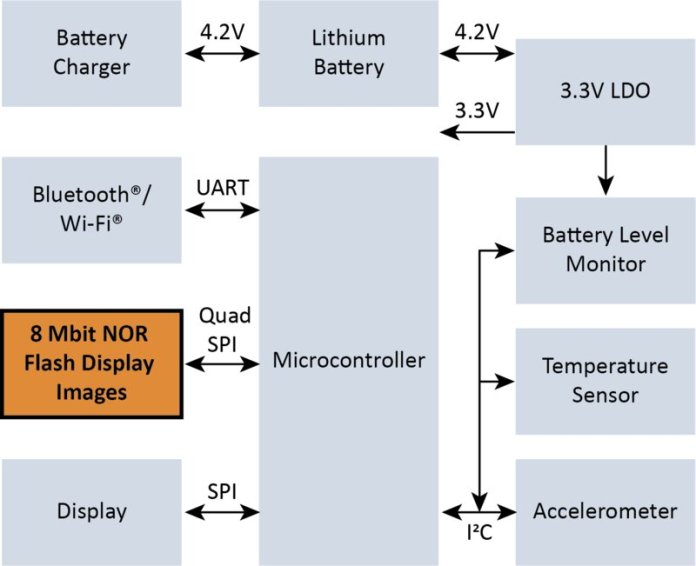

Small standalone and embedded systems — think garage door openers, electric drills, manufacturing line equipment, and medical analysis systems — typically contain an 8-bit or 16-bit microcontroller (MCU) surrounded by a collection of analog and sensor integrated circuits (ICs), display and communication interface ICs, and, on some occasions, SRAM, EEPROM, and NOR flash ICs that aren’t included in the selected microcontroller (see Fig. 1). End-equipment makers are happiest when these industrial or medical products continue shipping into the market for 20 years or even longer.

When an IC supplier announces an end of life (EOL) caused by a move to a new process node, it typically becomes a requalification scramble for these systems makers, diverting engineering resources and adding unexpected spend to existing programs. NOR flash ICs (typically 1 Mbit to 8 Mbits is all that is needed in these products) are a particularly burdensome longevity part. This occurs because the larger-density NOR flash family members (256 Mbit to 1+ Gbit) drive the memory vendors’ business decisions, so there is a constant push for smaller geometry processes and shorter product life cycles.

This article discusses the NOR flash longevity problem and Microchip Technology’s solution.

The outlook for low-density memory

Leading NOR flash suppliers correctly focus on their high-margin, high-volume, high-density memory parts. Every company has a responsibility to focus on its strengths so it can maximize profit while bringing the most value and lowest cost points to its customers. In the four decades of NOR flash, this has meant that the surviving memory suppliers have needed to leave behind their lower-density products of years past.

As the top-end density offering moves up, a few years later, the very bottom-density offering is EOL’d, and so goes the cycle on and on. For 20-year-product-life embedded system suppliers, these IC disruptions can mean not just a new version of the current supplier’s part but a new supplier as well.

One solution to this painful problem is to “future-proof” the system design by using a 128-Mbit NOR flash IC to hold 4 Mbits of user programming code. This approach can clearly create inefficiencies in power consumption and overall system cost. Another solution is to use a nontraditional NOR flash memory supplier that has other business reasons to supply the same memory product for 20+ years. That supplier may not have the economies of scale in memory volume to offer the lowest current cost point at the time of the first price bid, but over time, when considering likely requalification costs and the lost engineering resources to conduct those requalifications, it is most likely a much lower-cost answer to this supply problem.

Microchip identified this challenge years ago because it impacts a broad embedded customer base. The negative impact of this density trend on business plans and business objectives required a strategic course correction. The result is a nontraditional NOR flash memory IC supplier that offers serial SRAM IC, serial EEPROM IC, analog, and sensor IC products as well. These “other business reasons” provide the motivation to keep supplying low-density NOR flash ICs for as long as customers need them. Also, these memory product offerings currently stop above-64-Mbit densities where focused memory suppliers will continue to supply products for the next 20 or more years.

Recommended

NOR flash device features pre-programmed MAC addresses

Fig. 1 is a representation of the types of systems under discussion: an MCU surrounded by other ICs to give the embedded application life and purpose. In this example, the 8-Mbit device (highlighted) contains a few different display images that are shared via the touchscreen display output IC whenever the program code (embedded in the MCU, in this case) calls for it. The key characteristics of this external NOR flash memory IC are 8 Mbits, standard SPI interface, low standby current, low write current, small area, and production availability for 20 years.

Fig. 1: With the microcontroller at the heart of an embedded system, several other IC technologies, including NOR flash, are required for specific applications. (Image: Microchip)

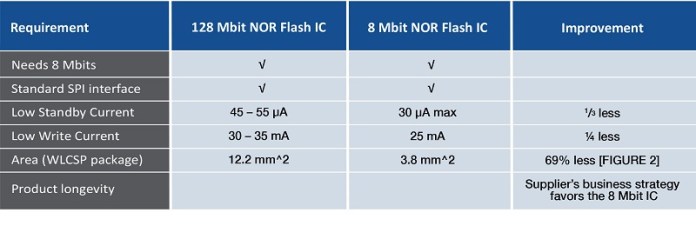

Table 1 is a comparison of two proposed solutions to deal with EOL low-density NOR flash: a 128-Mbit NOR flash IC for future-proofing and an 8-Mbit NOR flash with long-term availability from a nontraditional memory supplier. Clearly, the 8-Mbit NOR flash IC meets the embedded application’s requirements best.

Table 1: A 128-Mbit NOR flash IC compared with an 8-Mbit NOR flash IC reveals advantages. (Image: Microchip)

Using low-density NOR flash

As explained, while low-density NOR flash may not fit into the plans or strategy of large NOR flash suppliers, it is an excellent fit into an embedded company’s product offerings and strategy for a systems approach. For example, a typical home will easily have several dozens of embedded systems with 8-bit, 16-bit, or even 32-bit MCUs. Most of these systems do not require a large amount of code, whereby the NOR flash often provides program code, calibration data, calibration parameters, event logs, and more.

Even though many MCUs come with built-in flash to cover these jobs, there are situations, as in Fig. 1, when external NOR flash makes more sense for some of these applications. Common reasons given are the total system bill of materials (BOM) cost tradeoff versus offered MCU flash sizes, MCU function mismatch versus embedded flash sizes, quicker reflash time for test sets during line manufacturing, in-system reflash events for field upgrades, and more.

In addition, lower-gate-count application-specific integrated circuits such as field-programmable gate arrays and complex programmable logic devices use small NOR flash for in-application programming, boot code, and execute-in-place (XIP) operation. NOR flash memory ICs are perfect for XIP applications offering low standby power consumption and are directly accessible using a standard serial interface such as SPI.

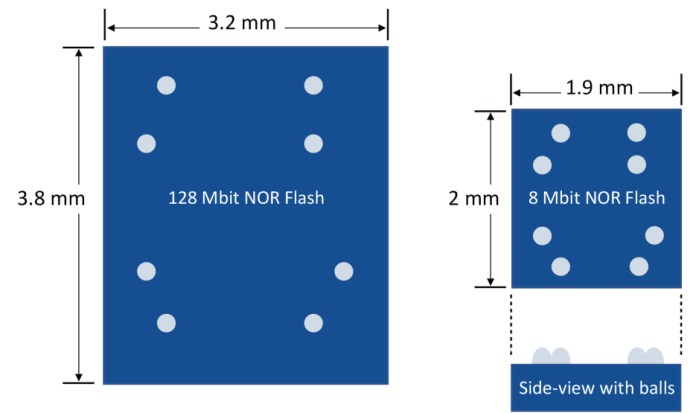

Available in eight-pin packages, such as an eight-lead SOIC and eight-contact WDFN (6 × 5 mm), low-density NOR flash memory devices are very board-efficient as well. For applications with limited board space, such as an electric toothbrush, a wafer-level chip-scale package (WLCSP) provides considerable package space savings (almost 69%), as shown in Fig. 2.

Fig. 2: The difference in packaging size for an 8-Mbit versus a 128-Mbit WLCSP can be quite significant, especially if space is critical. (Image: Microchip)

1000× faster reflash times

Even though Microchip is a nontraditional memory supplier, it makes a lot of flash memory. Billions of MCUs are shipped each year that include flash. Also, a significant technical and strategic advantage exists in a flash memory dubbed SuperFlash technology, acquired through Microchip’s acquisition of Silicon Storage Technologies (SST). These flash memory cells are structured to provide the industry’s fastest erase times, with 20× faster block erase times and 1,000× faster full-chip erase times compared with typical flash devices.

While reflashing a NOR flash is not common in the world of large NOR flash memory suppliers, it can become a huge advantage in small embedded systems by lowering manufacturing costs (such as reflashing the memory image on the manufacturing line to improve system test coverage) and offering a low-power and fast way to upgrade a field system.

Returning to the 128-Mbit comparison above, a 128-Mbit NOR flash (without SuperFlash technology) has a typical max block erase time of 0.7 seconds to 1 second. In contrast, an 8-Mbit NOR flash (with the SuperFlash enhancement) has a block max erase time of only 25 ms (30× faster). In addition to the time savings, the erase/rewrite power difference is ~800 ms × 33 mA on every block erase for a rewrite cycle.

NOR flash in new designs

Microchip Technology has a unique perspective on many segments of embedded systems, and NOR flash is an integral part of this insight. To provide confidence in designs that can have a useful life of dozens of years, it has an established practice to ensure availability for as long as customers need replacement products. While some suppliers may be exiting NOR flash memory products and even declaring EOL, this commitment can ensure availability for small, mid-sized, and even large-volume applications. This longevity ensures that customers can get the parts they need for their embedded systems — for as long as it is needed.

About the author

Grant Hulse is manager, product marketing, for Microchip’s Memory Product Division, leading strategic marketing initiatives in the area of nonvolatile memory. This includes the company’s EEPROM, EERAM, flash, SRAM, and other products used in data center and computing applications. Prior to Microchip, Mr. Hulse managed memory marketing for Atmel Corporation, which was acquired by Microchip in 2016. Earlier, he worked for several years as senior marketing director at Cypress Semiconductor. Mr. Hulse held successive prior leadership roles in engineering, business development, and marketing at startup and mature semiconductor companies that include Simtek Corporation, RF Magic, New Logic Technologies, AMI Semiconductor, and NEC Electronics in roles based in the U.S. and Japan. He holds a Bachelor of Science degree in electrical engineering from Brigham Young University and a Master of Science degree in electrical engineering from Stanford University. He completed the NEC Electronics Executive MBA program and has published industry articles and white papers on a broad range of topics throughout his career.

Advertisement

Learn more about Microchip Technology