TDK Corp. has unveiled several new sensor, laser, and microphone products at CES 2021. Three of the most advanced products announced include the TCE-11101 MEMS-based carbon dioxide (CO2) gas sensor platform, the InWheelSense energy harvesting and sensing module, and an ultra-small, full-color laser module.

TDK highlighted these upcoming new products during a CES briefing. Presenters included Sreeni Rao, Ph.D., senior director, emerging business, InvenSense, a TDK Group Company; Rakesh Sethi, Ph.D., general manager at the U.S. R&D Center for Sensors and Actuators, TDK, and Michael Chinn, senior vice president for information & communication technology at TDK Corporation of Americas.

TCE-11101 MEMS gas sensor platform

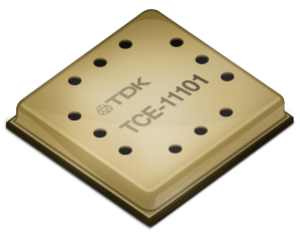

Driven by the need to monitor harmful gases in the environment, TDK has developed the InvenSense TCE-11101, a miniaturized, ultra-low-power MEMS gas sensor platform for direct detection of CO2 in the home, automotive, IoT, health-care, as well as in other applications. As part of the new SmartEnviro family, the platform’s small size (5 x 5 x 1 mm, 28-pin LGA package) and low power consumption enable consumer and commercial devices in all form factors that do not need to be wall-powered. TDK also noted that the platform requires minimal external components to complete the design.

The SmartEnviro platform is based on TDK’s unique sensing principle that is implemented in MEMS and proprietary materials that are developed by the company.

Air quality – indoors and outdoors – has become a number one public health issue with more than four million deaths a year attributed to pollution today, and some studies show the number is closer to six million per year, said Rao, during the presentation.

Studies have shown that the higher level of CO2 in a space directly correlates with lower cognitive abilities, which impacts a person’s ability to make decisions, have the proper attention space, and to be judgmental, he added.

“It turns out the CO2 levels in outdoor spaces or in indoor spaces is a big concern and it also turns out that carbon dioxide is a very difficult gas to monitor because it’s inert and it doesn’t react with chemicals, so while there is a need for monitoring carbon dioxide in an environment that we all work and live in, it is also a very difficult gas to measure.”

(Image: TDK)

TDK believes the TCE-11101 solves this challenge. By leveraging the company’s novel materials development, MEMS process technologies, and AI and machine learning capabilities, the TCE-11101 is orders of magnitude smaller than traditional sensors, consumes less than 1 mW of power, and provides accurate measurement of CO2 gas concentration, compared to existing solutions, including “bulky, power-intensive and expensive optical techniques” or “intrinsically inaccurate eCO2 approach.”

In addition to the extremely miniaturized form factor and ultra-low power, the TCE-11101 offers an extremely wide sensing range from 400 to 50,000 ppm, compared to most of the devices available in the market today, said Rao, which opens up applications that other devices may not be able to offer.

TDK also developed an integrated solution for an easy system design with a digital interface and algorithmic support that contributes to increased levels of accuracy, said Rao, providing a value proposition over the two existing options currently available at this point.

Those options are optical-based sensors that are bulky, power intensive, and expensive for most applications, but are effective in terms of performance, and at the other end of the spectrum is an eCO2 approach or devices based on the technique, which are inherently inaccurate because they don’t directly sense carbon dioxide, Rao explained.

The TDK solution offers a baseline accuracy of +/- 75 ppm +/-3% of measured value with better accuracy of CO2 concentrations under 2000 ppm. Minimum lifetime is estimated at 8.7 years. It also includes an ASIC that provides automatic calibration, reporting, and a serial interface for data output and configuration.

Based on the advantages of the TCE-11101 gas sensor, such as small size, ultra-low power, wide sensing range, and low cost, Rao believes it will open up new use cases for CO2 detection in a variety of new and existing applications.

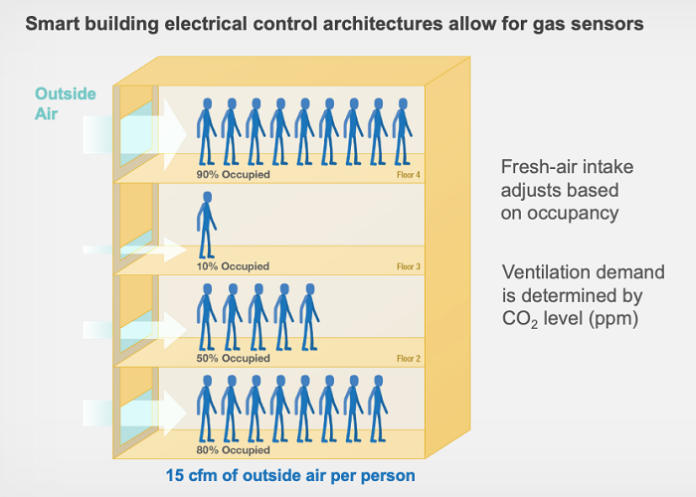

(Image: TDK)

One example cited is in demand controlled ventilation (DCV), where the TCE-11101 allows granular control of a HVAC system by accurately measuring CO2 levels that precisely indicate occupancy in a room or given space, which can be used to optimize energy consumption for HVAC in smart buildings or smart homes.

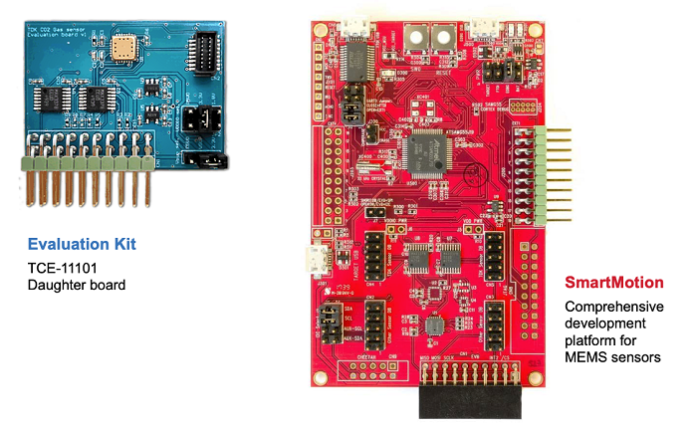

Samples are available now, followed by early production in mid-2021. An evaluation kit with supporting software is available for select early partners and customers.

(Image: TDK)

InWheelSense energy harvesting and sensing module

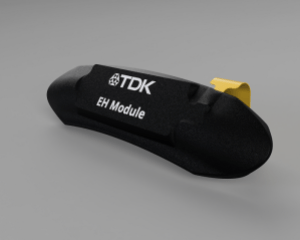

The InWheelSense piezo-based energy harvesting and sensing module with power, sensing, and connectivity is designed to mount on automotive tires in ADAS applications. The double-duty module converts the force of tire rotation into piezoelectric power and generates battery-less sensing and data collection and transmission from the wheel. The module can sense road surface conditions, wheel alignment, tire pressure, and other conditions in real-time, and can connect to roadside infrastructure for smart mobility applications.

(Image: TDK)

So why did TDK develop an energy harvesting + sensing module for automotive tires? There’s a massive digital transformation and electrification wave that is going on with the industry headed towards non-perception sensors from perception sensors, explained Sethi.

So TDK asked itself – ‘how can we do digital transformation across smart mobility applications, how do we do it sustainably, and how do we participate in the electrification of smart mobility and autonomous driving,’ he explained.

These three challenges are addressed by TDK’s existing portfolio of autonomous driving sensors and actuators; however, the wheel is the last part of the car that has not been digitized or electrified substantially, he added.

This is where the InWheelSense product comes into play.

Until now, environmental sensing for ADAS features has been performed by perception sensors like LiDAR, radar, image and infrared cameras, but there are challenging adverse conditions that many perception-based sensors are not able to see through, said Sethi.

Improved sensing performance during adverse weather and all terrain conditions can be provided by non-perception sensors (such as piezo, inertial measurement unit (IMU), ultrasound, and strain gauges) embedded in the tire or wheel, which can more accurately digitalize and classify driving and road conditions, according to TDK.

(Image: TDK)

The InWheelSense energy-harvesting (EH) module uses piezoelectric elements to generate electric power from mechanical motion or force, and by placing the device at the boundary between the tire and wheel, the module generates electricity using the force received from the road surface as the tire rotates. It achieves an average continuous power output of 1 mW when driving at 65 mph/105km/h. The operating temperature range is -40°C to 105°C.

“This module is placed in the bead area, which happens to be the maximum power generation area,” said Sethi. “This is untapped real estate in the wheel that is going to bring about a massive emergence of new applications and participation by various sensor makers.”

Not only does this EH module act as a power generation module, it also is a sensor for smart mobility, he added. “So this is the yin and the yang methodology of creating harmony between energy harvesting and energy sensing.”

The EH module can be used across all wheel sizes to generate as much power as needed. “There is no fundamental limitation in the power generated because both sides of the rim can accommodate up to 30 units of the module, which means as much power as you want can be generated at a cost that is scalable. “

Sethi noted that the solution has the capability to wire multiple modules in totem pole mode “for customers who are very hungry for larger power” and “are planning to run extremely high compute cycles in the wheel.”

(Image: TDK)

The EH module can sense various driving conditions using power changes as a result of speed, turning, and other changes in operating conditions, through analysis of the waveforms that are continuously generated. Because one waveform is outputted for each wheel revolution, the module can detect both speed during driving and road-surface conditions based on the shape of the output waveform.

The InWheelSense platform provides real-time data collection from additional wheel sensors (including accelerometers, barometric pressure and temperature) to the onboard computation unit. This control module platform includes power management, digital compute capacity, and low power data transmission using BLE. Data can be stored and/or processed through an inference engine in the control module, powered by an edge application processor. All the power needed is supplied by the energy harvesting power generator.

These non-perception sensors can work with connected transportation infrastructure such as smart bridges, traffic controls, and signage to communicate real-time data and support vehicle-to-pedestrian, vehicle-to-infrastructure and vehicle-to-vehicle networks. They can also be used in other applications besides automotive, such as in windfarms, where the sensors can be integrated into the blades to increase performance and improve maintenance.

Sethi also believes the data provided by the InWheelSense platform could open up a new “applification” service business model that combines the “sensor fusion data.”

TDK’s InWheelSense platform provides power generation in the wheel and enables non-perception sensing of the of the vehicle and road conditions in real-time with the data streamed as needed, explained Sethi. The potential source of scalable power for this battery-less system can enhance the business of TPMS [tire pressure monitoring system] customers and also embedded tire module customers, as well as open an opportunity for many new market players who want to provide technology-as-a-service or add features to robotaxis and other applications, he added.

An evaluation kit and samples are available for simple evaluations of the energy-harvesting module that can be attached to existing wheels. The kit enables wireless collection of data outputted from the device and power generation without additional equipment. Early production is expected in 2023 followed by volume production in 2025.

Ultra-small, full-color laser module

Aimed at augmented reality (AR) glasses and micro projectors that need ultra-small light sources, TDK has unveiled a full-color laser module prototype, equipped with three lasers (red, green, and blue), that measures less than half the size of a penny. When the colors are combined, they can create multiple colors including, yellow, purple, and even white, which is difficult to produce, according to Chinn.

One of the biggest growth areas for this device is AR glasses, said Chinn. But for widespread adoption it’s important that all of the electronic components that contribute to the AR solution are the smallest possible and optimized for stylish form factors, he said.

“One of the key enablers for market growth will be the superior performance of laser-based solutions for these applications, and also the potential for laser-based solutions to provide focus-free direct retinal projection, which enables some pretty interesting approaches to create AR solutions and potentially has the ability to enhance the visual capability of the approximately 38 million people worldwide who have a severely reduced visual capability,” said Chinn.

Other possible applications include femto projectors and automotive head-up displays, he added. “The brightness requirements for in-cockpit applications are rather more challenging.”

(Image: TDK)

The laser module prototype measures 6.7 x 5.5 x 2.7 mm, which would likely use a flexible printed circuit (FPC) connection, extending the length (including the terminal) to 8 mm. In addition to the small size, it also is lightweight, weighing only 0.35 g.

The wavelengths of the red, green, and blue laser diodes are 636 nm, 520 nm, and 455 nm, respectively, with an output power of less than 5 mW for each color. The module also provides a photodetector and thermistor to monitor internal temperature and prevent overheating.

TDK demoed the full-color laser module in the RETISSA Display 2, AR glasses from QD Laser Inc. In addition to AR and VR glasses, other applications include femto projectors and head-up displays for automobiles.

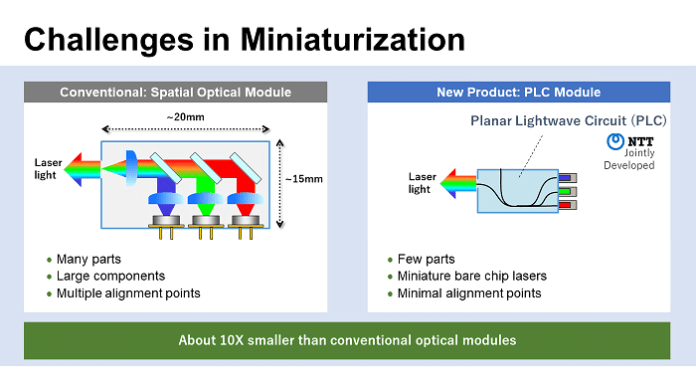

The ultra-small lasers solves two technical challenges: miniaturization and time to production. These challenges are solved by using a planar lightwave circuit (PLC) from NTT to combine each color into one optical path. The PLC and bare laser chips used in the new sub-assembly construction also require fewer points to align the position, resulting in a 10x smaller size compared to a conventional module.

(Image: TDK)

In addition, TDK provides high-precision and high-accuracy alignment through its high-speed, automated technology, which transfers, aligns, and bonds the laser chip to the PLC in five seconds, roughly 150 times faster than conventional modules.

This is a huge reduction in the assembly time, which is very important for driving long-term cost reduction as well, said Chinn.

An existing laser-based solution typically measures around about 20 x 15 mmm in size, which is quite large, and there are multiple alignment points for the different lasers, mirrors, and lenses, so it’s quite a challenge to assemble with high quality and repeatability, he explained.

TDK’s PLC approach using individual very small lasers – diodes, which are then combined with this PLC circuit can drastically reduce the number of parts and also reduce the number of optical alignment points, which is very important to speed up the overall assembly process, he added.

“Manufacturability or producibility is a key challenge for such small solutions, so we have also developed a high performance automated solution to drastically reduce the time it takes to assemble this laser module light solution.”

(Image: TDK)

Samples will be available in early 2021, followed by production in 2023. By 2025, Chinn expects to announce a second generation, optimized version with reduced form factors as well as optimized power consumption, increased spectral flexibility by adding additional laser elements in the module, and higher capability in terms of different colors and light outputs.

TDK will demonstrate these products, along with its portfolio of passive components, sensors, power supplies and batteries during CES 2021.

Advertisement

Learn more about TDKTDK America