Exxelia, a manufacturer of high-reliability capacitors and subsystems, has developed what it calls a breakthrough technology for film capacitors. The new Miniature Micro-Layer (MML) capacitors offers ultra-high energy density, claiming the highest capacitance per volume for film capacitors. As a result, the film capacitor family also saves board space and weight, while lowering component count.

The new film dielectric, rather than being wound in a cylindrical configuration, is constructed from stacked layers of polymer film, similar to MLCCs, said Exxcelia, in an email response. “This new dielectric material allows for much higher capacitance per volume that allows for significant weight and space savings.”

Key specifications include a wide capacitance range of 1 μF to 1000 μF and voltages from 50 V to 1000 V. The operating temperature range is -55°C to 140°C. There is no voltage derating up to 125°C.

Capacitance/voltage and size comparison between MML and polypropylene film capacitors. Click for a larger image. (Source: Exxelia)

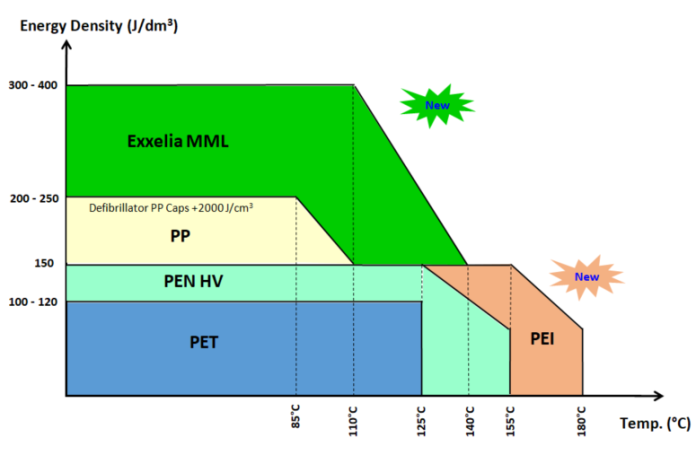

The company calls the MML capacitors a game changer with an energy density of 400 J/dm3. This allows for a tremendous reduction in size and weight compared to traditional polypropylene or polyester dielectrics, said Exxelia. The technology also offers an increased operating temperature up to 140°C and transient voltage protection.

Energy density comparison between MML and other film capacitors. Click for a larger image. (Source: Exxelia)

In addition, the MML capacitors allow for low-profile configurations. The company also noted several studies using control and DC-link functions for aircraft applications that show about a 50% reduction in size and weight compared to other film technologies. Compared with MLCC capacitors, one study shows a 70% to 90% reduction in weight with no capacitance derating with voltage applied and a low drift of <5% through the temperature range. Download the whitepaper for more information.

A single MML capacitor can replace clusters of stacked MLCCs, which also delivers the increased reliability of film dielectrics, said Exxelia. Also, compared to stacked MLCCs, the MML capacitors offer inherent self-healing properties together with low drift in capacitance over the temperature range (±5% max), low dielectric losses, and they are not prone to cracking due to thermomechanical stress.

Applications for the new capacitor include power supplies, DC-links, AC/DC/AC power converters, charge/discharge or power generation functions in commercial/military aircraft, satellite platforms and payloads, launchers, defibrillators, and downhole tools.

The MML capacitors are available in four different series with through-hole, SMD, or copper terminals. Samples in the DIL configuration are available now with the following ratings: 10 µF, +/-10%, 600 VDC; 13.5 µF, +/-10%, 600 VDC; and 36 µF, +/-10%, 600 VDC.

Advertisement