Output voltage ripple plagues various types of portable electronics products. Voltage ripple is an unwanted artifact generated by switching regulators, the dc/dc converters which supply power to board-level devices. A typical dc/dc converter in a well-designed circuit will generate a ripple voltage of around 1% of its nominal output, so a regulator producing a 2.5-V output can be expected to generate around 25-mV of output ripple. For some end products, this amount of ripple has no noticeable effect. But for others, it causes a marked degradation in performance.

Engineers designing small, portable end products have therefore looked for ways to stop ripple voltages from affecting sensitive circuits.

The favored method today is the LC filter, which can be made effective at the higher frequencies used by small buck regulators. The problem with these is that the frequency at which the filter becomes effective has to set low (typically up to 50 kHz) in order to achieve sufficient attenuation at the switching frequency; this results in large values for the capacitor and inductor.

A simple LC output filter can generally be expected to reduce this noise by a factor of 10 (20 dB), and sometimes by as much as a factor of 100 (40 dB). High-frequency spikes are attenuated even more.

Unfortunately, the space required for an effective double-pole LC filter of this type is considerable because of the size of the inductor and capacitor. When the common requirement for a semiconductor switch (to cut off power to the circuit when not needed, a power-saving tactic) is also taken into consideration, it is clear that the designer of a noise-sensitive circuit appears to be faced with an unappealing trade-off between either a clean power supply or a compact circuit design.

Since LC filters can also present problems of ringing and EMI, especially if lower-cost, lower-quality inductors and capacitors are specified, it is clear that designers will be ready for a new, less problematic solution to the problem of voltage ripple. This is the dilemma that Micrel has addressed with a new, patented noise attenuation technology: Ripple Blocker.

Compact size, enhanced performance

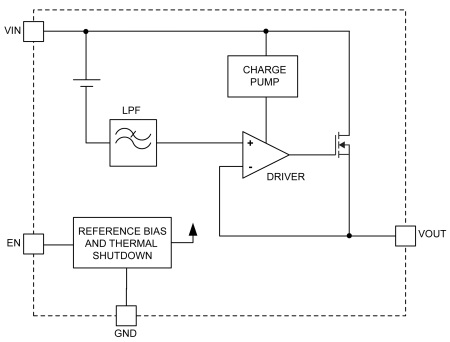

Ripple Blocker enables active filtering to be implemented in compact silicon integrated circuits, producing superior noise attenuation in a smaller board area than an equivalent LC filter. Its operation can be illustrated through a description of a Ripple Blocker voltage follower’ device, the MIC94300 (see Fig. 1 ).

Fig. 1: Functional block diagram of MIC94300 integrated load switch

The output of this device follows the input, but with a small, fixed 170-mV drop. This voltage drop is sufficient to ensure that the integrated power NMOS FET at the output can operate in its saturation region for high performance while maintaining high efficiency.

LDO regulators more commonly use an internal PMOS FET: the use of an NMOS FET is unusual, as circuitry required to drive them is more complex.

An NMOS FET, however, has the advantage of inherently better power supply ripple rejection (PSRR) across the targeted frequency range – and ripple rejection is the primary function of the MIC94300 device. PMOS FETs, by contrast, lose ripple rejection capability at frequencies above 10 kHz. Micrel has developed a patent-pending architecture for controlling the NMOS FET’s gate very efficiently, so that power losses here are unusually low.

The Ripple Blocker’s fixed voltage drop of 170 mV is independent of load current – the drop is set by an internal 170-mV voltage referenced to the input voltage. A low-pass filter passes the dc- and blocks the ac-component of the input voltage. The filtered signal is provided as a reference to the LDO so the output will follow the dc of the input but reject any ac-signal.

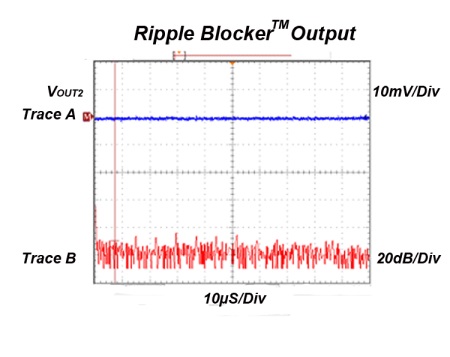

This technology has enabled the creation in the MIC94300 of a device offering both a low drop-out and high attenuation of voltage ripple across a wide frequency range. The attenuation performance can be seen in Fig. 2 — this is the output from the MIC23153, now filtered through the MIC94300 noise attenuator.

Fig. 2: Output from MIC23153 switching regulator after passing through a MIC94300 Ripple Blocker load switch.

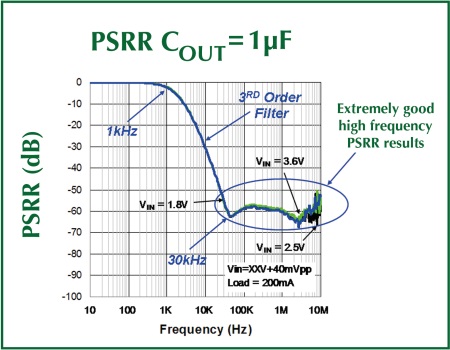

The MIC94300’s attenuation factor is around 1,000 (60 dB) from 30 kHz to 10 MHz (see Fig. 3 ). This is a 10 to 100 times improvement over the LC filter across the frequency range. These characteristics are ideal for noise-sensitive circuits using today’s buck switching regulators, which typically operate at fundamental frequencies of 500 kHz to 3 MHz.

Fig. 3: PSRR performance of the MIC94300 noise attenuating load switch.

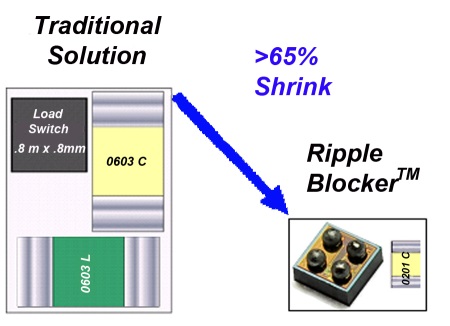

Noise attenuation performance, then, is superior to the conventional LC filter: at the same time, the MIC94300 offers a dramatic savings in board space (see Fig. 4 ). The MIC94300 has dimensions of 0.88 x 0.88 mm (in its chip-scale package version), integrates the filter circuitry, and a load switch in a single device. Externally, it only requires a small output and input capacitor (each of 1 µF). When compared to an LC filter and discrete load switch, a Ripple Blocker device can reduce the board space requirement by as much as 65%.

Fig. 4: An MIC94300 load switch with Ripple Blocker technology provides superior attenuation in a much smaller area

Ripple Blocker technology is implemented in a variety of devices, all of which, like the MIC94300, offer outstanding noise attenuation performance. The MIC94310 offers a choice of 18 fixed-output voltages ranging from 1.2 to 3.3 V. Both the MIC94300 and MIC94310 are rated for loads up to 200 mA. Versions rated for 500-mA loads are also available.

Clean power supply, no complications

Noise-sensitive designs in which board space is limited are the prime candidates to use the Ripple Blocker technology. Where noise sensitivity is at its most extreme, the extra 20 to 40 dB of noise attenuation provided by the device compared to an LC filter is also a powerful benefit.

For many designers, however, a highly integrated noise-attenuation device with documented performance offers the advantages of ease of use and convenience. Implementing a clean power supply with a Ripple Blocker device eliminates the need to design an LC filter, and also eliminates the complications involved in using an LC filter, such as the risk of ringing and EMI. A Ripple Blocker device, by contrast, is simple to design in, delivers guaranteed noise attenuation across a known frequency range and generates no unwanted EMI or other effects.

The Ripple Blocker can not only improve system performance, but it also reduces design time, complexity, and risk. For systems using today’s generation of high-frequency switching power regulators, in fact, there is no simpler or more compact way to produce a clean power supply.

Advertisement

Learn more about Micrel