Developed in Lab 22 at Australia’s CSIRO and designed by a Melbourne-based medical device company called Anatomics, a 3D-printed titanium sternum and rib cage have been planted into a 54-year old Spanish man’s body after he lost them to a chest wall sarcoma, a type of cancerous tumor that grows, in this case, around the rib cage.

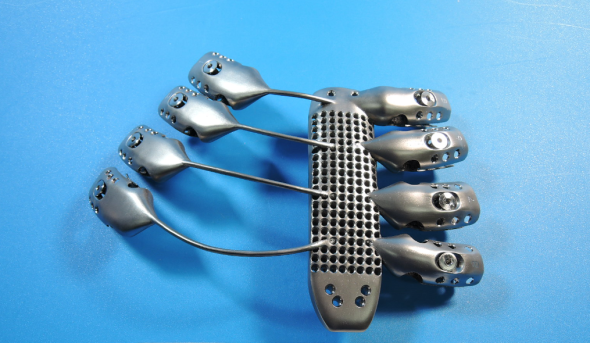

Due to the abnormal shape of the missing bone, doctors determined that a fully customizable 3D printed sternum and rib cage was the best option in recreating the complex geometry of the sternum and rib cage.

While this isn’t the first time surgeons have used titanium implants, it is the first they have used them for the chest, as they typically use flat and plate implants. The problem with these, however, is that they can come loose over time and increase the risk of complications. The surgical team believed the customized 3D printed implant could replicate the intricate structures of the sternum and ribs, providing a safer option for the patient.

Using high-resolution 3D CT scans of the patient’s chest, the surgeons determined which areas needed to be replaced, and turned to Anatomics, who used a $1.3 million electron beam Arcam 3D printer in Lab 22 to produce the prosthetic, the first in the world, which was then flown to Spain and surgically implanted in the patient.

Just 12 days after the surgery, the patient was discharged and recovered well.

The implant was designed with pieces that went over the remaining bone, allowing them to be attached securely with screws. The advantage of 3D printing is its rapid prototyping, which is essential while you’re waiting for life-saving surgery.

Source: CSIRO

Advertisement

Learn more about Electronic Products Magazine