By Maurizio Di Paolo Emilio, editor-in-chief, Power Electronics News

The demand for greater energy savings is constantly increasing. For product designers, this means paying attention to the key parameters of power devices, including high efficiency and low standby power consumption. In the case of AC/DC converters, energy transfer and conversion require careful design as well as optimization through test and measurement.

The AC/DC converter aims to convert the input AC signal into a variable DC voltage and then optimize it through a filter to obtain an unregulated DC voltage. AC/DC converters are mainly used in consumer devices, medical devices, industrial and process control systems, measurement equipment, semiconductor manufacturing equipment, and defense applications.

In a smart home, for example, power devices implement efficient hardware for AC/DC conversion with the aim of mitigating energy losses and achieving significant cost savings. Smart homes and smart offices need mesh control systems with many nodes, actuators, and low-power “always on” sensors.

The development and choice of an AC/DC converter can become a real challenge. However, the industry offers an increasing number of integrated circuits that incorporate innovative features and cut development time.

Choosing an AC/DC device

The selection of an AC/DC controller is related to several factors. Topology, control algorithm, and performance are just some of the critical aspects.

Protection functions are also an essential safety and reliability aspect in a power system. There are several types of protection, including those related to input (overvoltage and input voltage drops), output (overload, short-circuit, reverse voltage, and overvoltage), and temperature (overheating and ambient temperature rise). Very often, to meet specific requirements, a highly integrated solution usually delivers higher performance and lower power consumption than discrete components.

An AC/DC converter usually requires good switching for high energy efficiency. This can be achieved through innovative processes and technologies such as silicon carbide (SiC).

Each device is always subject to variability, but a well-designed system must provide robustness to these margins. The use of highly integrated AC/DC converters reduces the variability of design error and permits robustness and parametric tolerance.

The solutions

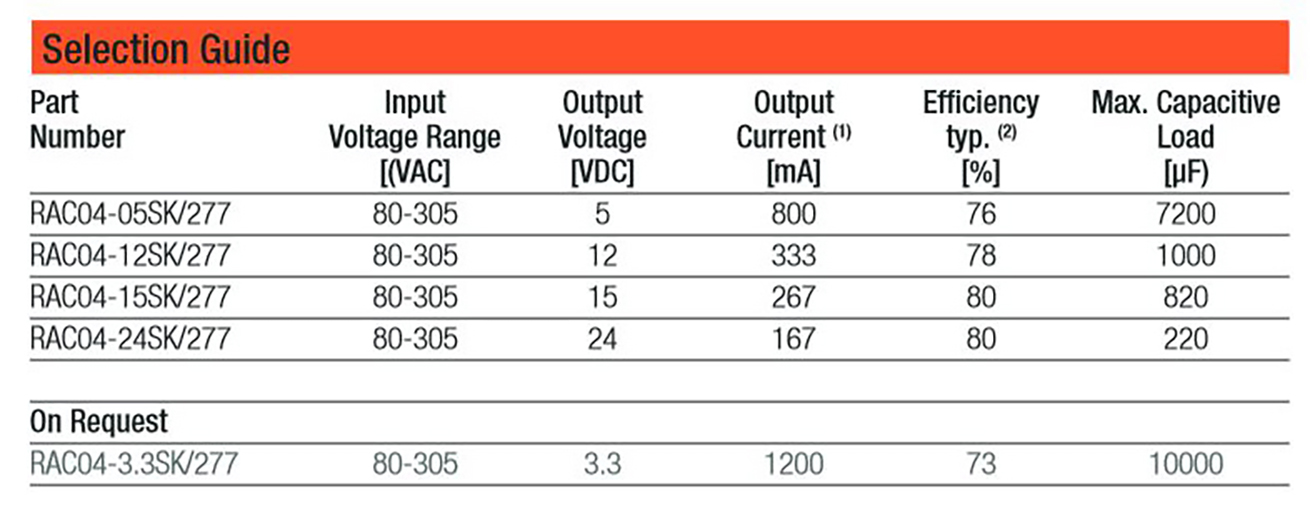

One example is the most recent addition to RECOM Power GmbH’s low-power AC/DC portfolio, the RAC04-K/277 modules for domestic and ITE applications. Offering a 4-kV insulation and operating temperature from –40°C to 90°C make them suitable for a wide range of operating conditions. The modules offer a peak load capacity of up to 150% for dynamic power requirements. In addition, the modules provide an input voltage range from 80 VAC to 305 VAC for all territorial requirements.

The RAC04-K/277 AC/DC modules also offer a reinforced Class II isolation rating for floating outputs and a wide margin to Class B emissions compliance without external components, which make them easy to install (Fig. 1 ).

Fig. 1: The RECOM RAC04-K/277 series (Image: RECOM)

RECOM also offers a 3-W solution, the RAC03-K, for a wide range of industrial applications. Both solutions support Ecodesign Lot 6 standby mode operation for worldwide applications in automation, Industry 4.0, IoT, and home automation.

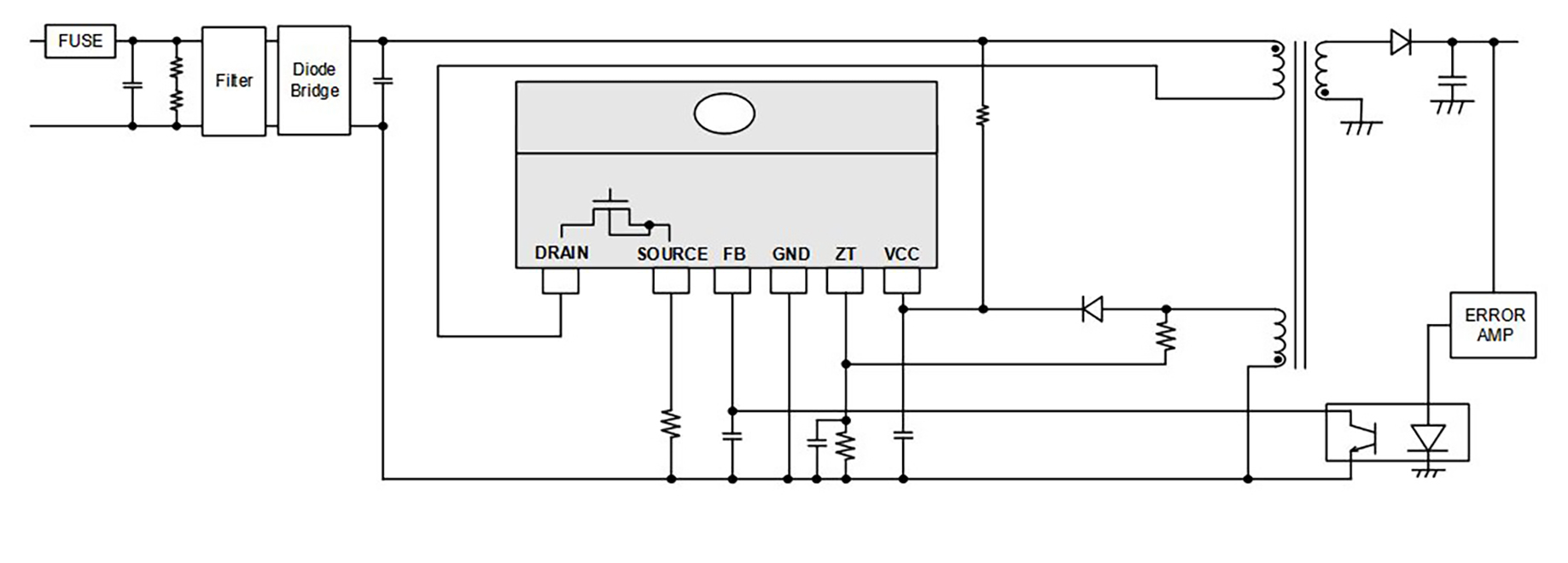

ROHM Semiconductor’s BM2SCQ12xT-LBZ series of AC/DC converters are optimized for industrial applications, including inverters used in high-power equipment. The series integrates a 1,700-V SiC MOSFET, providing greater energy efficiency, miniaturization, and higher voltage capacity than existing silicon power devices. The use of low-voltage SiC MOSFETs and IGBTs limits the amount of energy savings in the auxiliary power supply.

The series facilitates the efficient design of AC/DC converters by solving many of the problems encountered by designers using discrete solutions. The devices reduce the number of parts required compared to conventional designs (from 12 parts plus heat sink to a single IC) thanks to the integrated SiC MOSFET and optimized control circuits.

The device improves energy efficiency by 5% (and reduces power loss by 28%). These features result in a drastic reduction in size, increased reliability, and superior energy savings in industrial applications (Fig. 2 ).

Fig. 2: Typical application circuit with ROHM’s BM2SCQ12xT-LBZ (Image: ROHM Semiconductor)

The latest generation of AC/DC CoolSET integrated power stages from Infineon Technologies AG is made possible by the integration of its latest family of CoolMOS P7 700-V and 800-V superjunction MOSFETs in both DIP-Package 7 and DSO-12.

The quasi-resonant CoolSET series, integrated with an intelligent digital algorithm, allows the pulse-width modulation (PWM) controller to optimize the variation of the switching frequency under different AC line input working conditions. The series is intended for switch-mode power supply (SMPS) applications such as an auxiliary power supply for household appliances (e.g., washing machines, refrigerators, and air conditioning), set-top boxes, LCD/LED monitors, telecommunications/servers, and general-purpose power supplies with up to 43-W maximum output power.

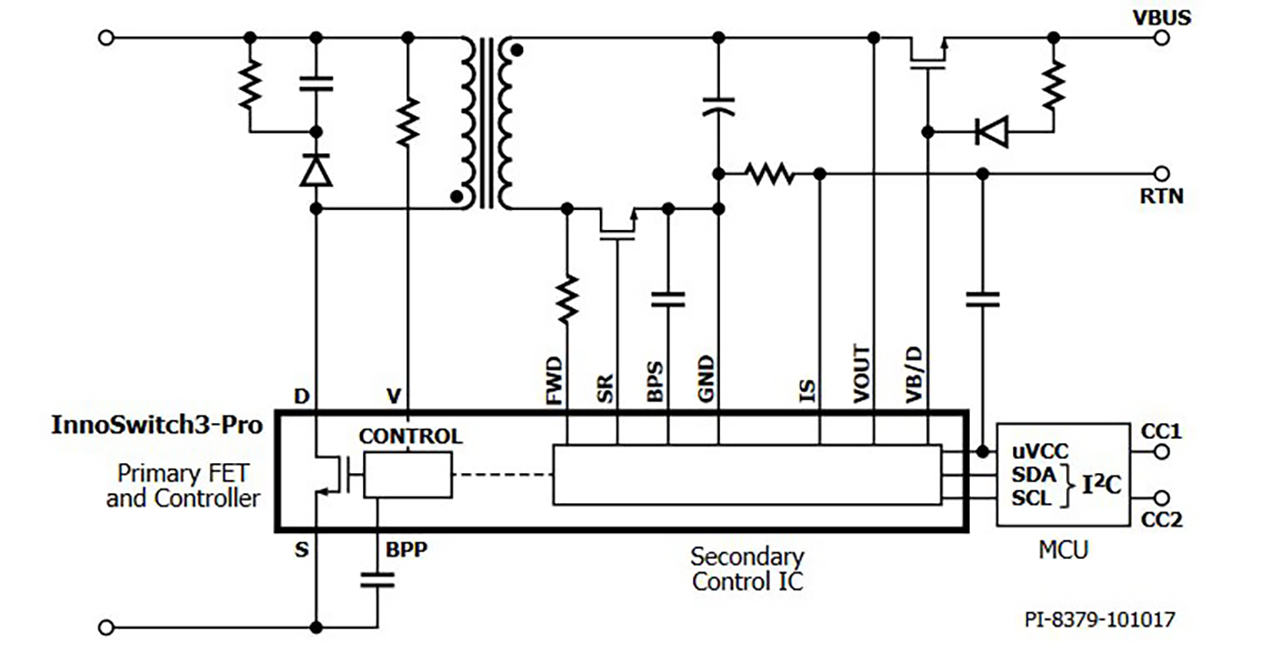

AC/DC converters based on gallium nitride (GaN) from Power Integrations offer up to 95% efficiency at full load. All three devices — the InnoSwitch3-CP, InnoSwitch3-EP, and InnoSwitch3-Pro — combine primary, secondary, and feedback circuits into one surface-mount package. The InnoSwitch3-CP and -EP variants are hardware-configurable, while the InnoSwitch3-Pro has a digital interface for software setpoint control, exception handling, and safety modes (Fig. 3 ).

Fig. 3: A typical application circuit with Power Integrations’ InnoSwitch3-Pro (Image: Power Integrations)

STMicroelectronics’ high-voltage AC/DC converters integrate an advanced PWM controller with a high-voltage power MOSFET, suitable for SMPSes. The portfolio, consisting of the VIPer, VIPerPlus, and Altair series, offers a wide choice of topologies, including near-resonant, flyback, and buck configurations with isolated or non-isolated implementations.

The VIPer series offers a 700-V HV vertical power MOSFET, while the VIPerPlus line features a rugged 800-V power MOSFET and a state-of-the-art PWM controller, consuming less than 30 mW (at 265 VAC) in standby. The Altair series integrates a 900-V MOSFET and a PWM controller, designed specifically for implementation without optoelectronic components, which reduces component count.

Dialog Semiconductor’s AC/DC converters offer both standalone digital controllers and digital controllers for embedded systems that incorporate PrimAccurate and AccuSwitch technologies, which reduce the number of external components. Dialog’s digital control cores improve energy efficiency by reducing no-load power consumption to virtually zero and improving load and line regulation via real-time waveform analysis.

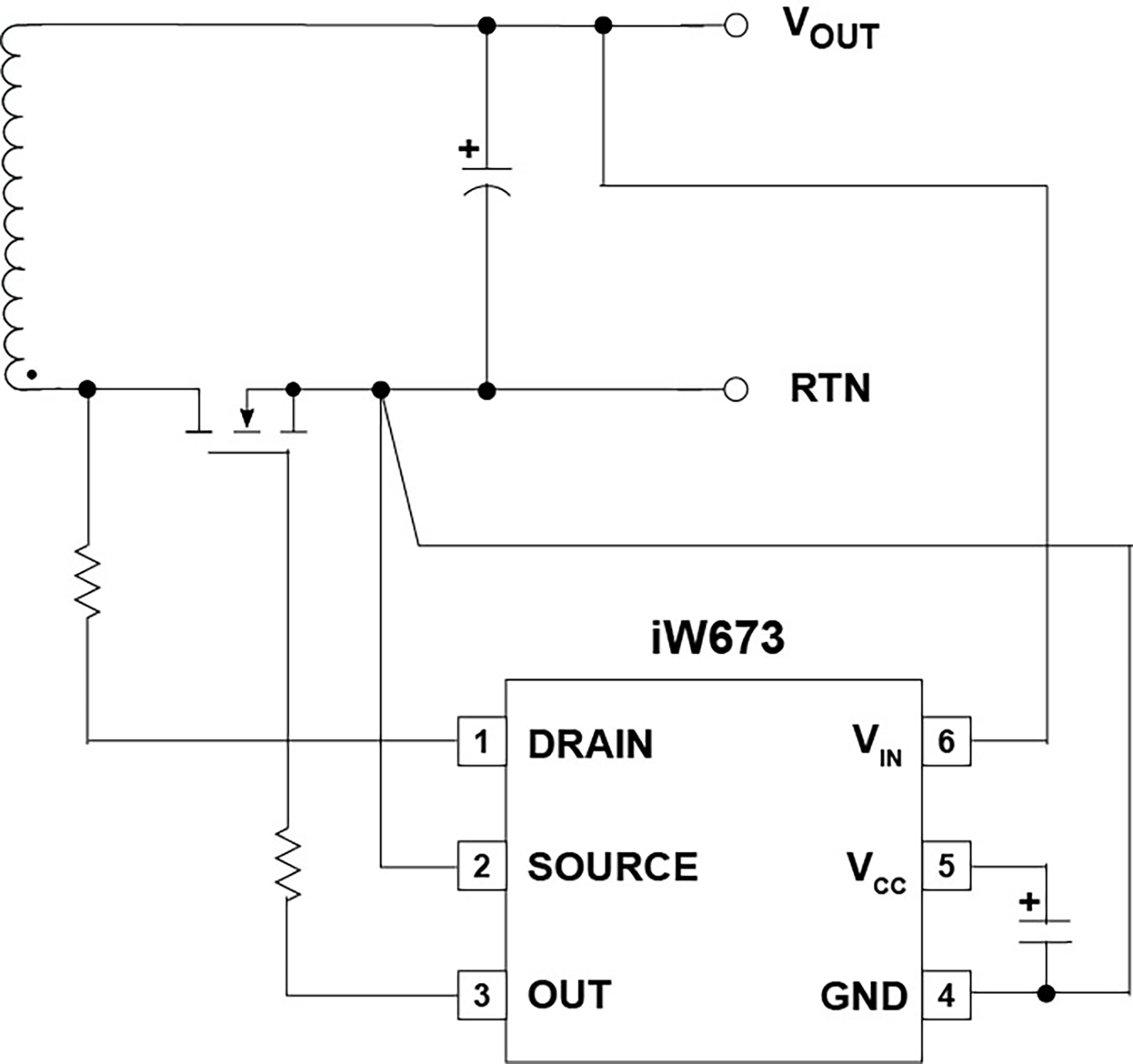

One example is Dialog’s iW673 synchronous rectifier controller, which emulates the diode rectifier on the secondary side of the flyback in combination with a MOSFET to reduce conduction loss. The power device uses proprietary adaptive digital shutdown control technology. This minimizes the synchronous rectifier shutdown times so that the parallel Schottky diode required by conventional synchronous rectifiers can be eliminated. The operating power consumption of the controller, excluding the driver, is less than 4 mW at no load (Fig. 4 ).

Fig. 4: A typical application circuit with Dialog Semiconductor’s iW673 (Image: Dialog Semiconductor)

Conclusion

The increasing demand for robustness, reliability, and efficiency has led to the development of innovative power technologies and components. SiC is one of those technologies. Normally used in high-power and high-voltage areas, SiC technology can also be successfully used in low-power AC/DC converters instead of the more common silicon MOSFETs. The increased efficiency of these new solutions reduces switching losses, heat dissipation, and, therefore, the need for heavy and expensive heat sinks.

Designers also need to consider global regulations and standards. Power supplies are subject to numerous regulations and certifications that involve complex and costly test and measurement activities. As examples, for AC adapters in which AC/DC ICs are integrated, CE certification is required, while in applications in which noise is a concern, EMI/EMC compliance is often required.

Advertisement

Learn more about Dialog SemiconductorElectronic Products MagazineInfineon TechnologiesPower IntegrationsRecom PowerROHM SemiconductorSTMicroelectronics