Commissioning a PCB assembler to build your prototype boards is an efficient way to save time and money, as well as avoid frustration. However, it's crucial to take component overages into consideration to ensure your project is delivered on-time. This means you must purchase additional parts to account for any losses that occur, especially with smaller components such as 0603, 0402, and 0201-sized capacitors, resistors and inductors.

PCB assemblers typically offer multiple types of services for assembling printed circuit boards. For instance, Advanced Assembly offers full turnkey, partial turnkey, and consignment services. If you opt for the full turnkey service, then Advanced Assembly will handle purchasing components, including part overages. Alternatively, if you select a consignment service, then you're agreeing to submit all the components yourself and take on the responsibility of providing enough extra parts.

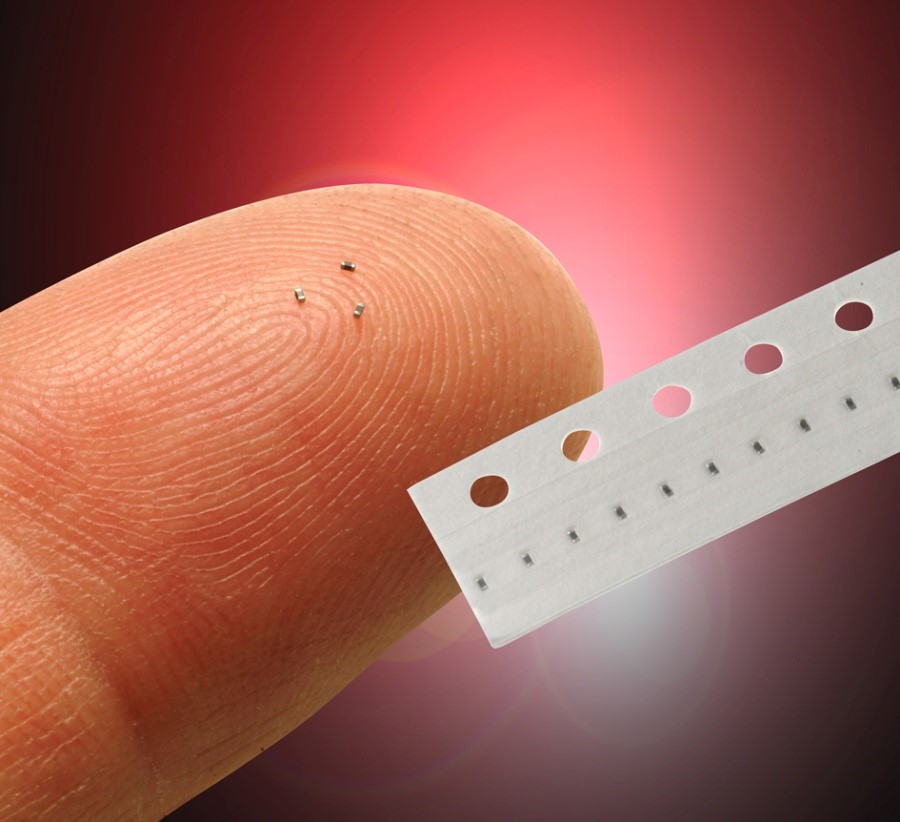

Why are extra components needed? Recall that surface-mount components are much smaller than their through-hole counterparts. For example, 0201-sized components, which are among the smallest, measure a mere 0.024 × 0.012 in. (0.6 × 0.3 mm); compared to a fingertip, they are practically invisible. Although surface-mount technology is very accurate, parts get lost during mount/dismount from the feeder.

You can hardly see 0201-sized components, pictured above on a fingertip.

You can hardly see 0201-sized components, pictured above on a fingertip.

For this reason, it is important to familiarize yourself with the specific overage guidelines outlined by your assembly partner, which includes the recommended number of extra components and correct shipping package procedures. Please note, each assembler requires a different amount of overage depending on its equipment and/or capabilities.

Assemblers will typically request that parts are packaged in reels, tapes, tubes, or trays; again, this depends on individual contractors and the capabilities of their surface-mount pick-and-place machines. For example, Advanced Assembly accepts loose IC parts and passives in continuous cut tape instead of requiring customers to purchase entire part reels for low-volume orders.

Lastly, the best practice for shipping electrical parts is to use antistatic packaging to prevent electrostatic discharge (ESD) from burning out the components. Also, it is a good practice to put your purchase order number in a visible location and provide special handling instructions if there are any (for example,” parts cannot be washed in an aqueous cleaner.”) All these details and more should be available on your assembler's website.

Taking the necessary steps to abide by overage guidelines and packaging requirements will ensure that your quick-turn PCB assembly order is completed in the shortest time possible and with the highest quality. To learn more quick-turn PCB assembly services, visit Advanced Assembly.

Advertisement

Learn more about Advanced Assembly