BY ANDREW BRYARS

Technical Manager

XP Power

www.xppower.com

Traditionally, lighting comprised some form of incandescent, fluorescent or halogen lamps. That has changed with the ever increasing popularity of light emitting diodes (LEDs) which are finding applications in both indoor and outdoor luminaires. The main drivers of this trend are energy savings, long service life, the robustness of solid state devices and the incredible flexibility that an LED luminaire can bring to a lighting application. However, to maximize these, the power source needs to be carefully chosen.

An LED will emit light when a voltage is applied across it and a current flows through it. The voltage must be equal to or greater than the LEDs forward voltage drop (typically in the region of 2 to 3 V) and the current for full brightness may be typically 350 mA for a 1-W LED which is practically the smallest size used in lighting applications. However, if the voltage applied exceeds the forward voltage of the LED then the current flowing increases exponentially meaning that the LED chip will become too hot and failure will occur.

The power source therefore needs to provide a suitable voltage at the appropriate current. The simplest way to achieve this would be to select a power supply with an output voltage above the forward voltage of the chosen LED and to limit the current to the maximum specified by the LED manufacturer using a current limit resistor. The down-side of this approach is that one of the main benefits of LED lighting – that of high efficiency, is compromised by the power dissipated by the current limiting device.

A further problem with this approach is that the LED junction temperature affects its forward voltage. As a power supply’s output voltage is fixed, this in-turn means that the voltage across the current limiting device changes and hence the current will change too. The changing current will affect the amount of light being emitted and decrease the reliability of the LED. The best approach is to drive the LED from a constant current source. This allows the current to be set to the maximum specified by the LED manufacture to achieve greatest efficiency and reliability, or to achieve the exact brightness required and also to remove the effects of junction temperature as the LED or ambient temperature changes.

One of the benefits of using LEDs in lighting applications is the ease of varying the brightness of the light. This can be achieved by varying the current through the LED which proportionally varies the amount of light emitted, however, running the LED with less than its maximum current reduces the efficiency and may result in slight changes in color. A better way is therefore to pulse the current between zero and maximum to vary the average light emitted. As long as this is done at a high enough frequency to avoid the pulsing being seen as flicker by the human eye this is the optimum way to achieve dimming. Pulsing of the current will usually be done at a fixed frequency with the ratio of zero to full current being changed. This is the pulse width modulation (PWM) method.

Selecting a power supply

The type of power supply selected for a lighting application will be based on several factors. First, the environmental considerations: Is the application for indoor or outdoor use? Does the power supply need to be water-proof or have any special IP rating? Will the power supply be able to use conduction cooling or only convection cooling?

What is the overall power that is required? A single luminaire may only require a small power source but a complex system may need ones supplying hundreds of watts. Also, will other features be required? For example, will the power supply be required to work in simple constant voltage mode or constant current mode? Will dimming be required?

From a regulation perspective, will the overall system need to operate within certain harmonic current limits? Will it need to conform to the safety standard for lighting or will an ITE power supply be adequate?

In these energy-aware times, how efficienct does the power supply need to be and does it need to comply with any input power requirements when the lamps are turned off?

Safety standards

There are various standards that apply to lighting systems. Internationally there is IEC61347 Part 1 of which covers the general safety requirements of lamp control gear and Part 2 Section 13 which is applicable to power sources for LED modules, the US have UL8750 and Europe has EN61347 following the IEC format of section naming.

Harmonic currents

A lighting application will generally require the harmonic current emissions to meet the requirements of EN61000-3-2 and the class of equipment which covers lighting is class C. Within this class there are one set of limits for above 25-W active input power and another set for 25-W and below. However, the standard specifically only mentions discharge lighting for 25-W and below.

To meet the limits for above 25 W will generally require power factor correction and, as the limits are calculated as a percentage of the fundamental rather than as an absolute value of amps, it may be better to use a power source designed specifically for lighting applications rather than an ITE type power supply. However, an ITE power supply will probably meet the limits as long as the lighting load is above 40 to 50% of the power supply’s full load rating.

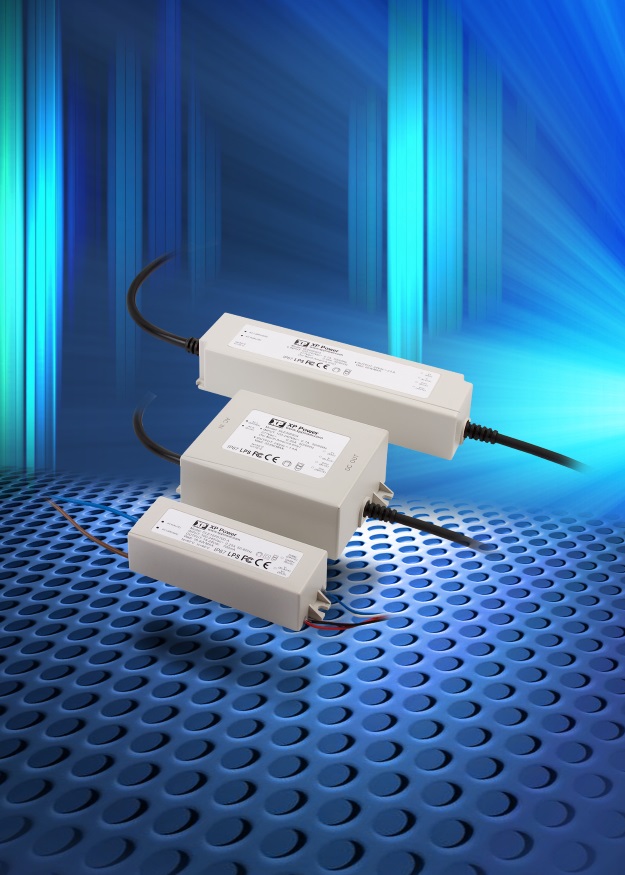

An example of a power supply series specifically designed for LED lighting applications is the IP67-rated DLE series from XP Power (see Fig. 1 ). The range comprises 15, 25, 35 and 60-W models and complies with safety specifications EN61347 and UL8750.

Fig. 1: An example LED power supply, the DLE series of 15 to 60 W

LED configurations

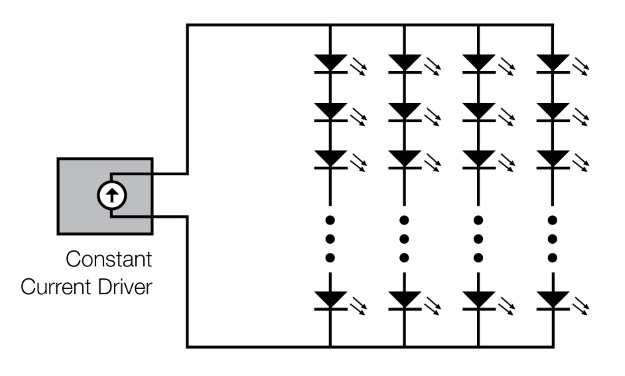

Some lighting applications may use just a single LED. The power used by this will typically be around 1W as the forward voltage is in the range of 2 to 3 V and forward current around 350 mA. Although this will produce a bright source of light, it is more probable that LEDs will be used in an array of some kind within a luminaire or group of luminaires to produce a brighter and more even light source. The LEDs will be generally arranged in one of four types of configuration. Placing the LEDs in series, parallel or a matrix (a combination of series and parallel) configurations enables them to be driven from a single power source. The fourth configuration utilizes multiple channels which require multiple power sources.

In this configuration the individual LEDS are arranged in series (see Fig. 2 ). This gives the advantage that the same current flows through each of them resulting in the same brightness of light given off. Another advantage is that if one LED fails in short circuit, the other LEDs are unaffected and hence are still lit. A disadvantage is that if one LED fails in open circuit, then current flow is interrupted and all the other LEDs turn off. A further disadvantage is that if many LEDs are needed to produce the amount of light required then the total sum of the forward voltages can necessitate the use of a power source with quite a high output voltage.

Series configuration

Fig. 2: LEDs connected in series

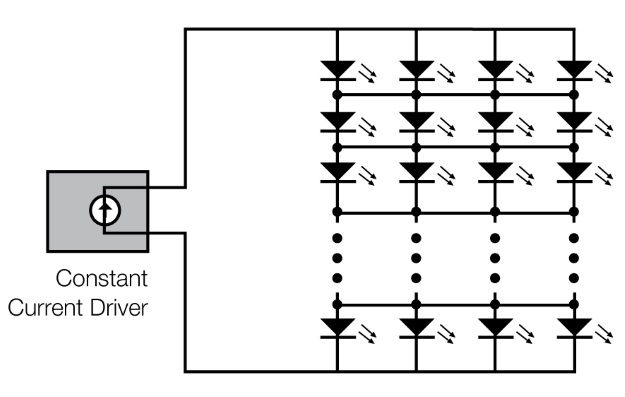

Parallel configuration

Fig. 3: LEDs connected in parallel

When connected in parallel (see Fig. 3 ) the LEDs may still be arranged in two or more strings of LEDs in series. The advantage is that for the same number of LEDs, that is, the same brightness, the power source could have a lower output voltage as the number of LEDs in each string can be reduced. Another advantage is that if one of the LEDs becomes open circuit in one string then the other strings are unaffected and the luminaire will still produce light albeit at a reduced brightness. The disadvantage is that the current in each string cannot be precisely controlled from a single power source due to the slightly different forward voltages present in each string and so a current balancing device in each string may be needed which could reduce the overall efficiency.

Matrix configuration

Fig. 4: LEDs connected in a matrix configuration

In a matrix layout (see Fig. 4 ), the LEDs can be arranged in a similar manner to that of parallel configuration but there are links between each LED form string to string. The big advantage of this configuration is that if a single LED becomes open circuit, there is still a path for current to flow through all the other LEDs in that string and so light output is hardly diminished. The main disadvantage is that it is more difficult to control the current in each string as a current balancing device cannot be used. This means that the LEDs used must have a closely match forward voltage which could add to the cost.

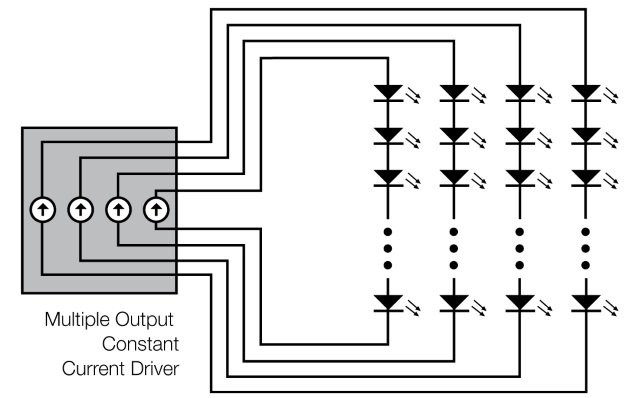

Multiple channel configuration

Fig. 5: LEDs connect by the multiple channel method

Using this approach, the LEDs are arranged in series in multiple strings arrangements (see Fig. 5 ) similar to the parallel and matrix configurations. This has the benefit that the total string voltage can be reduced for any given brightness required and as each string is fed from an individual power source the failure of any one string will not affect the other strings in any way. A disadvantage is that the power source will be more costly as each string has an individual output however it does allow for more flexibility in applications where the brightness of one string needs to differ from the others or where individual string dimming is required.

Advertisement

Learn more about XP Power