From simulating the interactions between software and hardware that fuel the Internet of Things to better understanding the full spectrum of advanced structural materials, the newly released ANSYS 16.0 offers advanced functionality enabling engineers to rapidly innovate new products.

ANSYS 16.0 delivers major advancements across the company's entire portfolio, including structures, fluids, electronics and systems engineering solutions — providing engineers with the ability to validate complete virtual prototypes.

“Global enterprises have already embraced ANSYS as the engineering simulation standard for proven physics, high performance computing solutions and a unified modeling environment,” said Jim Cashman, ANSYS president and CEO. “ANSYS 16.0 builds on that 45-year legacy by delivering even more game-changing functionality. By taking advantage of these new capabilities, enterprises can bring their products to market faster by reducing or eliminating their reliance on physical prototypes. And by fully leveraging the capabilities of this new release, they can unlock the promise within their products.”

“ANSYS solutions already complement our product development process perfectly, so we're looking forward to the new capabilities offered in ANSYS 16.0,” said Robert Terhune, mechanical engineer at 4moms, which develops some of the most innovative and safe baby gear on the market. “Validating prototypes on the computer using ANSYS simulation software, in addition to physical tests, drives us to higher levels of innovation while getting our products to market faster and more cost-effectively.”

Highlights of the release include:

Enabling Connected Electronic Devices. The pervasive connectivity of electronic devices, evidenced by the Internet of Things, requires a higher standard for hardware and software reliability. ANSYS 16.0 delivers capabilities to verify electronics reliability and performance throughout the design process and complex electronics industry supply chains.

As part of the release, ANSYS is introducing the ANSYS Electronics Desktop. This single-window, highly integrated interface brings electromagnetic, circuit and systems analysis into a seamless working environment to maximize productivity and to ensure users are following simulation best practices.

Another important new feature in ANSYS 16.0 is the ability to create 3D components and integrate them into larger electronic assemblies. This modeling approach can facilitate the creation of wireless communication systems, which is especially useful as these systems become more and more complex. Simulation-ready 3D components are created and stored in library files that can be added to larger system designs without the need to apply excitations, boundary conditions and material properties.

“The Internet of Things is changing the way that nearly every product is created,” said Larry Zu, president of Sarcina Technology. “That creates unique challenges for Sarcina Technology's high-performance application-specific integrated circuits and PCBs. The advances in ANSYS 16.0 enable Sarcina to create our leading products faster and more reliably, helping to connect the components of the Internet of Things quicker than ever.”

Simulating the Total Spectrum of Structural Materials. Reducing weight while improving structural performance and design aesthetics is a challenge many engineers face. Thin materials such as sheet metal and new substances such as composites are often part of the solution, but these choices present simulation challenges.

Sheet metal and plate steel are common traditional material forms used to minimize weight while delivering required structural performance. ANSYS 16.0 accelerates the process for engineers to model these thin materials and define how parts are connected in a complete assembly.

ANSYS 16.0 provides new functionality for composite designs and comprehensive tools for understanding the solution results. Composites are another material alternative to drastically reduce weight, but they are difficult to model because of their non-homogeneous properties and their dependence on the manufacturing process to deliver maximum performance.

ANSYS 16.0 also provides advanced solutions for elastomers like rubber, which are often used in seals and vibration dampers. Seals can become severely distorted and come into contact with other parts, which adds to the complexity of the simulation. ANSYS 16.0 features adaptive remeshing, which refines the mesh in highly distorted areas without the need for the user to stop the simulation manually.

Contact simulation between multiple parts has also realized many advancements in ANSYS 16.0. These are some of the most challenging simulations for structural analysis – especially with the expansion beyond traditional engineering material.

“The contact improvements released with ANSYS 16.0 will be very useful to further refine the modeling of stent deployment in cerebral aneurysms,” said Mathieu Sanchez, co-founder and R&D director, IRRAs Technology. “The combination of better contact management and the new visualization and customization tools available in ANSYS 16.0 should help us to bring engineering simulation benefits to the surgeons.”

In addition to new capabilities and enhancements, ANSYS 16.0 delivers improved solver performance to provide users with a faster time to solution.

“As part of Intel's close collaboration with ANSYS, we're excited to see them take a leadership role in delivering Mechanical 16.0 to market to address the HPC needs of Windows users with Xeon Phi,” said Charles Wuischpard, vice president Data Center Group, general manager Workstations and High Performance Computing at Intel Corporation. “This release takes full advantage of Intel® Xeon® processors and Intel® Xeon Phi™ co-processors to bring new levels of performance in simulation. This announcement underscores the momentum we're seeing for Intel HPC products across the industry.”

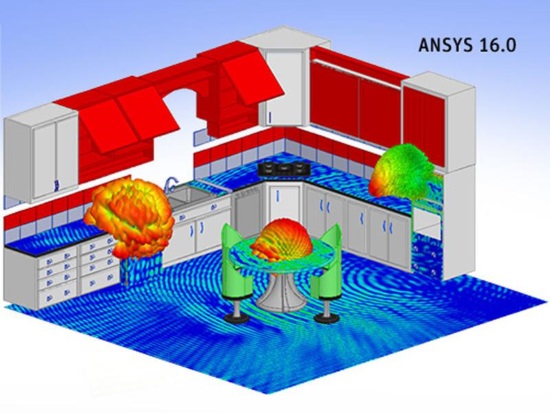

Simplifying Complex Fluid Dynamics Engineering Challenges . While manufacturers are constantly innovating their products to capture more market share, it comes with a challenge: engineers need to study more complex designs and physical phenomena — with less time. ANSYS 16.0 reduces fluid dynamics simulation time for complex models by up to 40%.

This release further reduces the time for optimizing design changes by leveraging the adjoint optimization technology and making it more practical for engineers to use. A new adjoint designer tool enables engineers to perform multi-objective shape optimization, including constraints. They can now use the adjoint solver and model up to 50 million cells.

Engineers designing turbomachinery equipment of all sorts – from pumps and fans to compressors and turbines – will benefit from significant simulation speed-up thanks to HPC scalability extending to thousands of CPU cores. Furthermore, continued advances in modeling transient blade row interaction will extend and improve engineers' ability to simulate the complex unsteady flow phenomena found in such rotating machinery as aircraft engines and power generation turbines.

Enabling Model-based Systems and Embedded Software Development. Virtually every industry has experienced growth in innovation based on systems including electronics, mechanical subsystems and embedded software. This trend has led to a number of challenges, which are changing how companies design and develop these complex systems. ANSYS 16.0 provides enhanced capabilities for both developers of systems and embedded software.

ANSYS 16.0 features extended modeling capabilities, enabling hardware and software engineers to define the intricacies of a system and its subsystems operations. This is crucial because as systems become more complex, engineers need greater definition of their operations. Systems and software engineers can better collaborate on joint projects, reducing development time and effort. ANSYS 16.0 addresses this need with the addition of behavioral diagram modeling.

Within the aeronautics domain, ANSYS 16.0 provides a model-based approach that satisfies the requirements of DO-330, the tools qualification document within DO-178C, for the highest levels of safety requirements. DO-178C, Software Considerations in Airborne Systems and Equipment Certification, is the new document that such authorities as the Federal Aviation Administration, the European Aviation Safety Agency and Transport Canada will use to approve all commercial software-based aerospace systems. ANSYS 16.0 is the first tool to meet that new certification requirement.

Introducing a Unified Multiphysics Environment. As part of the launch, ANSYS is introducing ANSYS AIM™ , an innovative, immersive simulation environment that lowers the barrier to entry for multiphysics simulations. AIM simulation uses proven ANSYS technology packaged in a new intuitive environment, accessible to the entire engineering organization. AIM's guided simulation process paradigm delivers high levels of automation and provides opportunities for customization to automate engineering best practices.

About ANSYS, Inc.

ANSYS brings clarity and insight to customers' most complex design challenges through fast, accurate and reliable engineering simulation. Our technology enables organizations ― no matter their industry ― to predict with confidence that their products will thrive in the real world. Customers trust our software to help ensure product integrity and drive business success through innovation. Founded in 1970, ANSYS employs over 2700 professionals, many of them expert in engineering fields such as finite element analysis, computational fluid dynamics, electronics and electromagnetics, embedded software, system simulation and design optimization. Headquartered south of Pittsburgh, U.S.A., ANSYS has more than 75 strategic sales locations throughout the world with a network of channel partners in 40+ countries. Visit www.ansys.com for more information.

Advertisement