Meet Hadrian, an Australian brick-laying robot capable of laying 1,000 bricks per hour and constructing a property’s framework at a rate 20 times faster than a human bricklayer — and because Hadrian doesn’t eat, sleep, or get drunk after hours, it can construct approximately 150 homes a years. So remember, the next time you see a rowdy warm-blooded 21st century Luddite parading down the street while proclaiming that robots “took our jobs,” you have robots such as Hadrian to thank.

Named after Hadrian’s Wall in the United Kingdom, Hadrian is the latest example human ingenuity spawning capable and affordable machines, with increasingly versatile functions. Designed by an aeronautic and mechanical engineer named Mike Pivac, Hadrian was created as a response to decreasing number of available Australian bricklayers, whose average age is 50. Mike has been designing Hadrian over the course of a decade, drawing his inspiration from technology he absorbed during a stint in the Air Force.

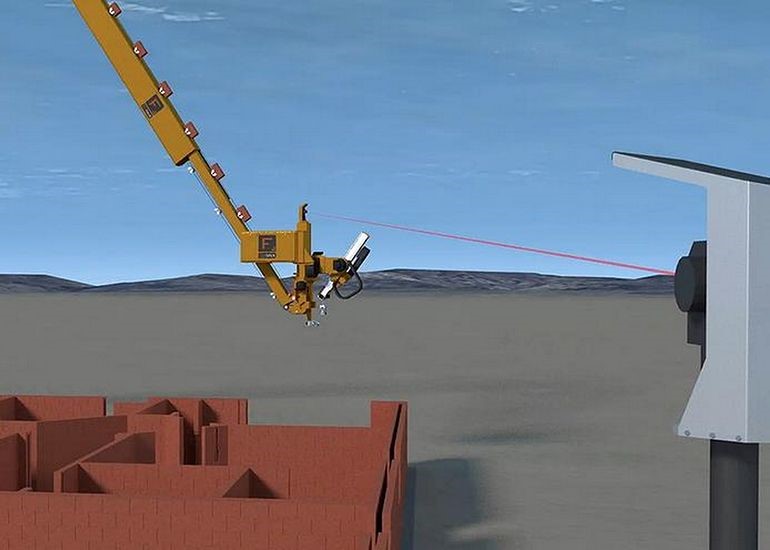

The robot attributes its heightened level of productivity to an articulated telescopic boom that auto-corrects itself 1,000 times per second, allowing it to compensate for vibrations and sway similar to the way 3D printers function. At its core is information sourced from a 3D CAD floorplan of the home, specifically designed for brick placement. Once each individual brick is laid in place, Hadrian even administers the mortar or whatever adhesive is selected, and applies pressure using the head of the boom.

“The Hadrian reduces the overall construction time of a standard home by approximately six weeks,” explains Mike Pivac, brother of Mark Pivac and CEO of Fastbrick Robotics, the firm responsible for manufacturing the robot. “Due to the high level of accuracy we achieve, most other components like kitchens and bathrooms and roof trusses can be manufactured in parallel and simply fitted as soon as the bricklaying is completed.” Together, this improves site safety, reduces the level of waste created during the construction process, and cuts down on wasteful emissions as well.

Up until the present, Fastbrick Robotics has spent seven million Australian dollars developing the Hadrian, but a recent acquisition of company by DMY Capital Limited promises to speed up the process through a larger spending coffer. While the current prototype is mounted on an excavator, the finished design will Hadrian situated on a truck bed for easier site to site mobility/

Source: Gizmag

Advertisement

Learn more about Electronic Products Magazine