The move to aircraft fly-by-wire from manual flight controls has put strains on the use of commercial-off-the-shelf (COTS) components in avionics systems. The probability of failure is increasing as these components take on more flight functionality. Mitigation of these failure mechanisms is critical for the advancement of these systems. Can COTS alone rise up to the challenge? Or is there a derivative COTS product that can harness key properties to debunk failure? Ruggedized COTS in the form of enhanced products (EP) is that derivative. This article elaborates on the details of EP and what it means for high-reliability avionics systems.

First, let us define some common failure mechanisms in COTS components. With the recent increase in the price of gold and compounds, such as nickel-palladium-gold, many COTS vendors are switching to copper bond wires to reduce costs. The reliability of copper has not been proven in mission-critical applications, harsh environments, or applications where long-term dormant storage (10 to 20 years) is required. This is a common research topic among third-party/government regulatory entities, such as Aerospace Corporation and the Defense Logistics Agency (DLA). MIL-PRF-38535, which these entities regulate, does specify copper for bond wire use; however, DLA qualification requirements have never been defined, nor has the DLA allowed for copper in Class Q (military) or Class V (space) products. The switch to copper in COTS and automotive products (Q100) can pose lifetime and reliability concerns. In order to be considered ruggedized for avionic-type applications per MIL-PRF-38535, gold bond wires or nickel-palladium-gold are required.

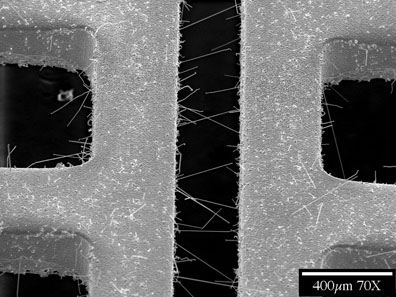

Another failure mechanism in COTS comes from using pure tin (Sn) in lead-frame coating. Historically, lead (Pb) has been the primary element in the lead-frame finish, as this creates a highly reliable bond to the PCB landing pad. However, lead poses many health-related risks. And this has led to replacing lead with tin in COTS material sets (No Lead). However, when tin is subject to large amounts of stress, it can crystallize and create a tendril that can cause electric shorts. Fig. 1 (See: http://nepp.nasa.gov/whisker/) illustrates the growth of tendril “whiskers” from tin, which extends across two adjacent pins in a lead-frame, causing a short.

Figure 1: Tin “whiskers” forming off of a lead-frame (tendril growth). Source: NASA EEE Parts and Packaging.

COTS’ intent of moving to tin is not being challenged here. Since many avionics systems can undergo large amounts of stress, using tin should be reconsidered. Lead-based material, when handled correctly, eliminates the risk of such shorts occurring when the device must be used in high-stress applications. For ruggedized COTS applications, it would seem that lead must be used, unless there is another answer.

One other failure mechanism occurs during the qualification of plastic components in avionics systems. The entirety of methods used to qualify plastic components is out of the scope of this article. Delamination, or lifting of the die from the die-attach internal to a component package, can occur during temp cycling and stress testing. Certain mold compounds and die-attach materials are more susceptible to delamination and, typically, these materials are cheaper, but they are often used in COTS components. The mitigation of delamination risk by constructing a roughened lead-frame, improved die-attach, and better mold compounds — all of which are proprietary and often are more expensive — should be considered for ruggedized COTS components.

Another dynamic in avionics systems is long-term use or dormant storage of components. A highly accelerated stress test (HAST) can expose failure mechanisms under these usage circumstances. The description of this stress test can be found on the JEDEC website. Generally, all components go through HAST qualification. However, the length of time for the HAST qualification is typically shorter for COTS components (for example, 96 hours). For ruggedized COTS, a 250-hour HAST test is highly recommended.

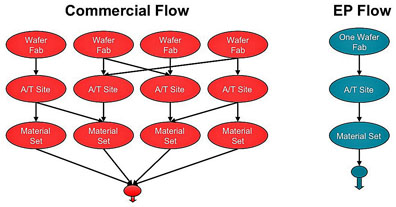

Once a component is qualified for an avionic system, long-term consistency in manufacturing must be taken into consideration. Manufacturing a component in a new semiconductor fabrication plant or assembly and test (A/T) site from the original baselined flow can cause risk of failure that the original qualification did not predict, and re-qualification should be required. The same is true for the component’s material set. Change in any of the manufacturing or materials can create many unaccounted variables.

If a change is required, the component vendor must issue a product change notification (PCN) to allow the component to be re-qualified, if deemed necessary. This consistency and PCN introduces added costs to the component. The same is true for A/T sites and material sets. The COTS flow variability, when compared to the consistency of “baseline control,” is shown in Fig. 2 . A ruggedized COTS component must use a single baseline.

Fig. 2: Commercial versus controlled baseline enhanced products (EP) flows.

In some programs, all components require a standard microcircuit drawing (SMD). True COTS components do not offer such drawings and, hence, require the designer to create an internal specification. The DLA has released a vendor identification drawing (VID), which has the component vendor’s data sheet and revisions. Avionics designers then have an industry standard part number and do not need to create a drawing internally. All VID components can be found on the DLA’s website (Defense Logistics Agency).

Texas Instruments’ enhanced products leverage the depth of the commercial TI portfolio while providing the abovementioned enhancements for a true ruggedized COTS offering. These products all offer a VID drawing to accelerate the documentation and procurement process (TI enhanced products).

Advertisement

Learn more about Texas Instruments