A team of researchers at the Institute of Physical Chemistry of the Polish Academy of Sciences (IPC PAS) have designed a battery that runs on air. Dubbed the ” bio-battery,” the power source is fueled by a biofuel cell in conjunction with a special electrolyte, and can produce up to 1.6 volts of electricity for an extended period of time when allowed to draw oxygen directly from the air. The device could provide a safer means of delivering power to internally implanted medical devices with electronic parts such as artificial pacemakers and cochlear implants.

Bio-batteries are safer

Special batteries are necessary to safely power medical implants within a human body, as typical batteries contain acids and bases that are otherwise harmful if leaked. For this reason, a trade-off must be made between the size of the battery and the insulation, thereby resulting in larger batteries offering increased insulation. The casing that houses the active components in the battery winds up weighing significantly more than the components themselves. Biofuel cells such as the one developed by Dr Martin Jönsson-Niedziółka and his colleagues require no such casings to function. Instead they draw power from electrodes inserted in the body, thus eliminating the use of acids and bases altogether.

Zinc-oxygen batteries

Dr. Jönsson-Niedziółka compares the undertaking to producing a battery by sticking electrodes in a potato, but with a focus on the human body as well as biofuel cells and improving the cathode of battery. His team’s experiments rely on the principles behind zinc-oxygen batteries, which are nothing new, having been used to create batteries prior to the popularization of alkaline batteries. The novelty in the IPC PAS team’s approach is the use of zinc-oxygen biofuel cells in combination with a special cathode to produce as much as 1.75 volts for a few hours. The glucose-oxygen biofuel cells used in other labs only generate 0.6 to 0.7 volts of electricity.

How it’s made

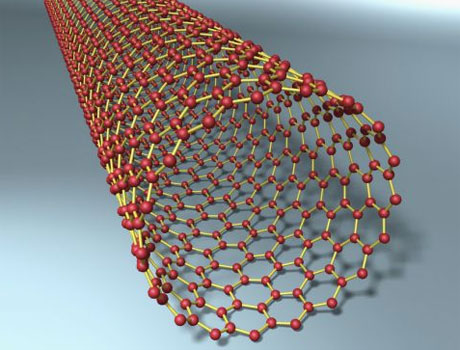

Professor Marcin Opałło of IPC PAS states that many years of work were necessary to construct the first cathode out of enzymes, carbon nanotubes, and silicate matrices. The biofuel cell begins working after a zinc electrode is fixed on the wall of a small container, upon which an electrolyte is poured and the electrode is introduce into it. This causes the pores within the silicate matrix to receive oxygen from the air, and hydrogen ions from the electrolyte fluid. Afterward, oxygen reduction is initiated to active the enzyme center. The carbon nanotubes, in turn, move the electrons from the exterior of the semipermeable membrane.

Carbon nanotubes that transport electrons. Imagine courtesy of The Guardian.

Biotech cooperation

Dr. Jönsson-Niedziółka tells us that the biggest bottleneck in developing this technology is attributed to the limitations of biotechnology of present. The cell with the biocathode is only able to deliver a steady 1.6 volts of power for a limited span of one and half weeks, and he believes this is attributed to the steady deactivation of the enzyme in the biocathode. “Here not everything is dependent on us, but on the progress in biotechnology. The lifetime of a biofuel cell with our biocathode could be significantly prolonged.”

Another challenge faced by the scientists at the IPC PAS to be overcome before developing biofuel cells based on their design is the challenge common to all biofuel cells: the limitations placed by low electrical power. Nevertheless, the research presented here is an important step in the miniaturization of batteries to be used in biomedical technology.

Visit Phys.org and The Polish Academy of Science for more information regarding this research.

Advertisement

Learn more about Electronic Products Magazine