BY MAJEED AHMAD

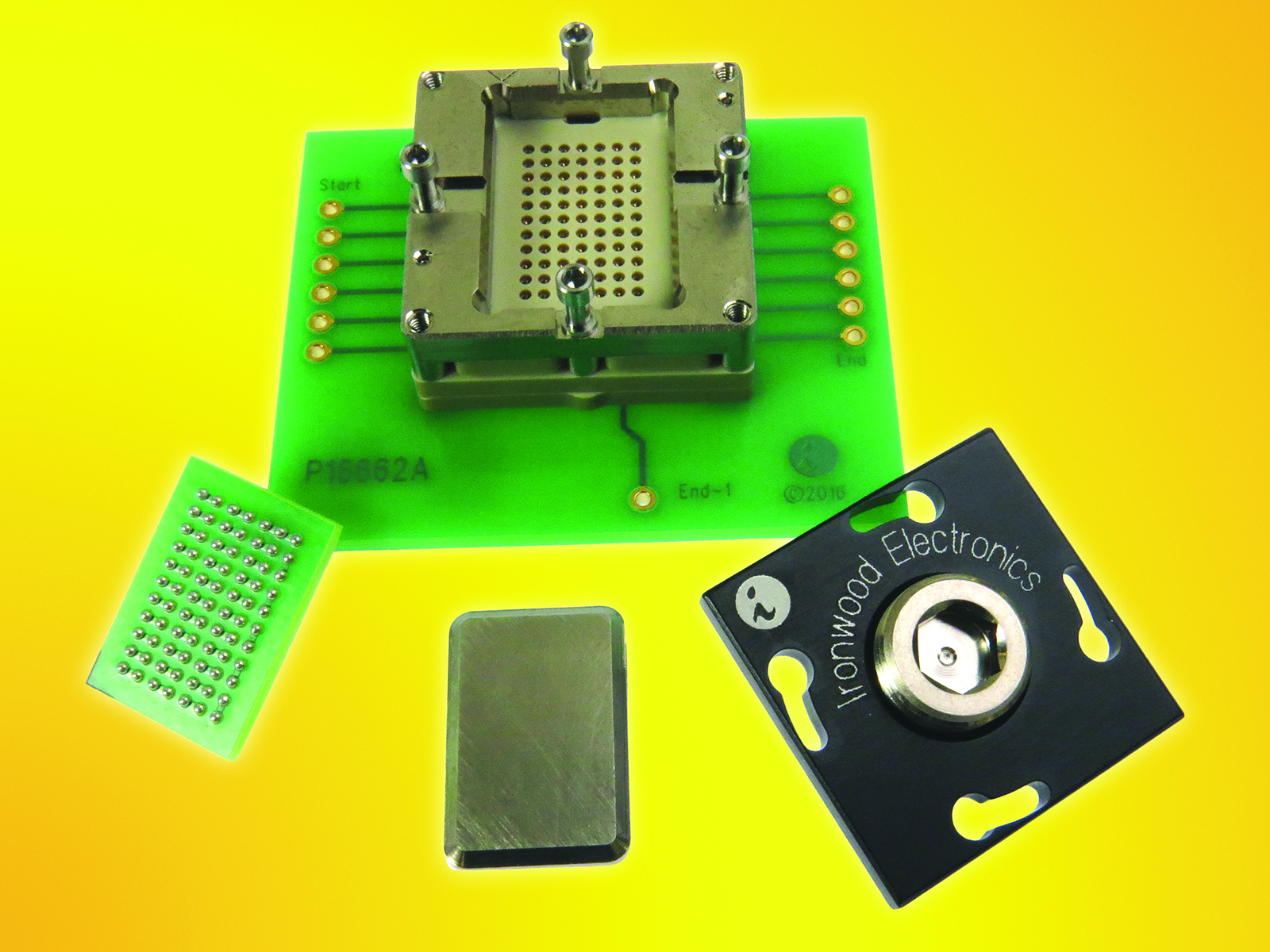

Ironwood Electronics has unveiled a new socket for testing ball grid array (BGA) devices; it uses a compression screw to apply downward pressure and thus allows the device to conveniently interconnect to the target PCB. The 77-pin BGA socket is mounted using supplied hardware on the target PCB with no soldering.

The contactor in the Ironwood’s SBT-BGA-6537 test socket is a stamped spring pin with 31-g actuation force per ball and cycle life of 125,000 insertions. And the self-inductance of the contactor is 0.88 nH, insertion loss

Advertisement

Learn more about Ironwood Electronics