Scientists at the University of Illinois at Urbana-Champaign have created organic robots that are powered by 3D-printed muscle cells and controlled with electrical pulses. These “bio-robots” are the beginning of a new form of robotics, meshing organic material with synthetic compounds in a clever way that takes advantage of the ability of living cells to regenerate.

The experiment was led by Professor Rashid Bashir, head of bioengineering at the University of Illinois, the same Professor Bashir credited for pioneering organic robots in 2012. Those earlier robots, made from 3D-printed hydrogels and living rats’ heart cells, were revolutionary, but they had strict limitations: The heart cells powering the micro-machines’ movements could not be sped up or slowed down, nor turned on or off.

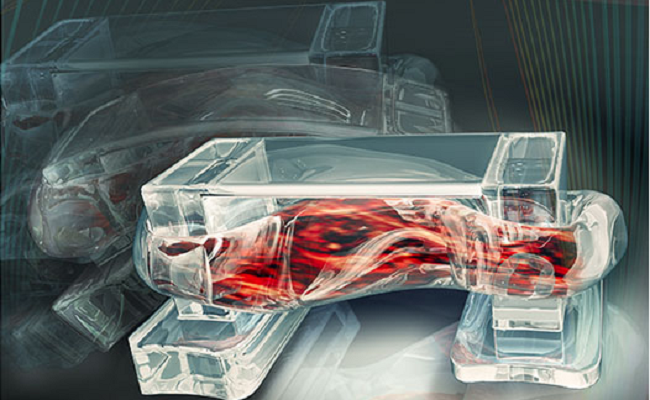

Two years and many prototypes later, Bashir and his team have innovated the design, rats’ heart cells with 3D-printed skeletal muscle cells, an alternative that can be manipulated using electric pulses. The new design draws its inspiration from the muscle-tendon-bone juncture found in vertebrae: a 3D-printed hydrogel serves as a sturdy, yet flexible joint, while two posts anchor a strip of muscle to this joint the way tendons attach muscle to joint. Adjusting the frequency of the electric pulses on the muscles controls the robot’s speed; the higher the frequency the faster the muscles contract.

“Skeletal muscles cells are very attractive because you can pace them using external signals,” Bashir said. “For example, you would use skeletal muscle when designing a device that you wanted to start functioning when it senses a chemical or when it received a certain signal. To us, it’s part of a design toolbox. We want to have different options that could be used by engineers to design these things.”

Now that the “on” and “off” switches are out of the way, Bashir and his team are working on developing a way to steer the bio-bots in different directions using light or chemical gradients. But before that becomes a reality, the team must first integrate neurons into the muscle fibers and re-engineer the hydrogel backbone to permit the movement in the first place.

“The idea of doing forward engineering with these cell-based structures is very exciting,” Bashir said. “Our goal is for these devices to be used as autonomous sensors. We want it to sense a specific chemical and move towards it, then release agents to neutralize the toxin, for example. Being in control of the actuation is a big step forward toward that goal.”

Though in its infancy, the technology represents a huge step in developing a controllable biological machine that could someday be trained and programmed to work. The effect this could have on drug delivery, surgery, implants, and diagnostics is immense, establishing a new paradigm for medical treatment.

Via Illinois.edu

Advertisement

Learn more about Electronic Products Magazine