BY SOL JACOBS

VP and General Manager

Tadiran Batteries

www.tadiranbat.com

Billions of electronic devices will soon be interconnected through the cloud-based Industrial Internet of Things (IIoT). Many of these industrial-grade devices will need to be “truly wireless” using primary and rechargeable lithium batteries to eliminate the need for hard-wiring to the electrical grid, which is often impractical, and can cost up to $100 per foot to install.

Typical battery-powered IIoT applications include transportation infrastructure, energy, environmental monitoring, smart manufacturing, healthcare, smart buildings, and industrial automation. If the device is easily accessible and operates within a moderate temperature range, then consumer batteries may make sense based on total lifetime cost, which needs to factor in all costs associated with future battery replacements. Generally, the more remote the application, the greater the need will be for an industrial grade lithium battery.

Identifying the right power management solution

Given the evolving nature of the industrial IoT, careful consideration needs to be given to the choice of power supply, which includes primary (non-rechargeable) lithium batteries and energy-harvesting devices working in tandem with rechargeable lithium batteries or supercapacitors.

Wireless devices that draw low-average daily current are predominantly powered by primary bobbin-type lithium thionyl chloride (LiSOCL2 ) chemistry, which offers unique advantages over all other lithium chemistries, including higher energy density, higher capacity, the widest temperature range, and a lower annual self-discharge rate.

The operating life of a bobbin-type LiSOCL2 cell depends largely on its annual energy usage and its annual self-discharge rate. To conserve energy, most remote wireless devices utilize a low-power communication protocol to support multi-platform interoperability and distributed computing. Battery life is extended by maintaining the device mostly in a “standby” mode drawing little or no current, then periodically querying the data, only “awakening” if pre-set data thresholds are exceeded.

In many cases, more energy is lost through annual battery self-discharge than through actual battery usage. How a battery is manufactured affects its annual self-discharge rate. A superior quality bobbin-type LiSOCL2 cell can feature a self-discharge rate of 0.7% per year, retaining nearly 70% of its original capacity after 40 years. Lesser quality bobbin-type LiSOCL2 cells can have a self-discharge rate of 3% per year, exhausting 30% of their capacity every 10 years.

The main drawback of a standard LiSOCL2 cell is an inability to deliver high pulses. This can be overcome by combining a standard LiSOCL2 cell with a patented hybrid-layer capacitor (HLC). The standard LiSOCl2 cell delivers low background current to power the device is in its “standby” mode, while the HLC delivers high pulses required for data interrogation and transmission.

Alternatively, supercapacitors can be used to store high pulses in an electrostatic field rather than in a chemical state. This technology is commonly deployed in consumer electronics, but has drawbacks for industrial applications, including short-duration power, linear discharge characteristics that do not allow for use of all the available energy, low capacity, low-energy density, and very-high self-discharge (up to 60% per year). Supercapacitors linked in series also require cell-balancing circuits.

Rechargeable batteries will also power the IIoT

Certain applications may be well suited for energy harvesting, with rechargeable Lithium-Ion (Li-ion) batteries being used to store harvested energy. The use of an energy-harvesting device hinges on numerous factors, including the reliability of the device and its energy source; its expected operating life; environmental requirements; size and weight considerations; and the total cost of ownership.

Inexpensive consumer-grade Li-ion cells have a life expectancy of less than 5 years and 500 recharge cycles and operate within a moderate temperature range from 0° to 40°C. If the application involves remote, inaccessible locations and extreme temperatures, then an industrial-grade Li-ion battery is probably preferred for delivering up to 20 years of operating life with 5,000 full-recharge cycles, an expanded temperature range from –40° to 85°C, and the ability to deliver high pulses (5A for a AA-size cell). Industrial-grade Li-ion cells are also constructed with a hermetic seal, whereas a consumer rechargeable battery use a crimped seal that may leak.

The solar-powered parking meter

One notable example of rechargeable Li-ion batteries being used to deliver true wireless connectivity the IIoT is the IPS solar-powered parking meter (see Fig. 1 ), which offers a cost-saving solution that eliminates the need to hard-wire metropolitan sidewalks.

Fig. 1: Rechargeable Li-ion batteries can deliver the high pulses needed for two-way communications for wireless networked solar-powered parking meters.

These wireless networked solar-powered parking meters offer state-of-the-art functionality, including: multiple payment-system options; access to real-time data; integration to vehicle detection sensors; user guidance and enforcement modules; all linked to a comprehensive web-based management system.

Small photovoltaic panels gather the solar energy, with industrial-grade rechargeable Li-ion batteries delivering the high pulses needed for advanced, two-way wireless communications, thus ensuring 24/7/365 system reliability.

Tracking the herd

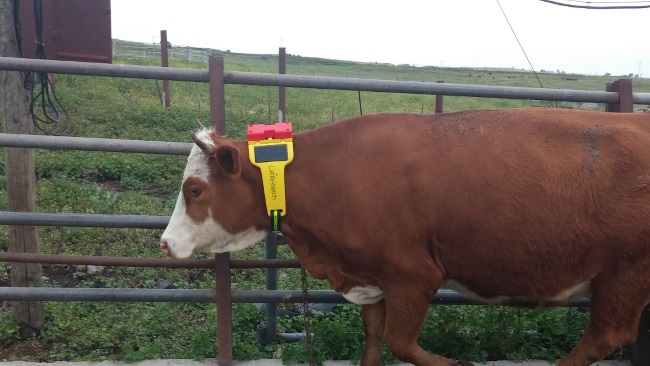

An innovative asset-tracking application is CattleWatch. This system places solar-powered hub collars on 2% of the cattle herd, while the remaining cattle are outfitted with collar tags or ear tags (see Fig. 2 ).

Fig. 2: Solar-powered hub collars help form an in-herd wireless mesh network. The collars require an industrial-grade Li-ion rechargeable battery to provide the high pulses needed for communications.

The collar and ear tags communicate with the hub collars to form an in-herd wireless mesh network. The hub collars communicate to the Internet cloud via the iridium satellite, thus giving ranchers real-time access to data monitoring animal behavior, including herd location, walking time, grazing time, resting time, water consumption, in-heat condition, and other health events, including instant alerts by smartphone of perceived threats from predatory animals or poachers.

An industrial-grade Li-ion rechargeable battery was required to deliver high pulses to power advanced two-way communications. In addition, supercapacitors would have added size and weight, less comfortable for animals to wear. The choice of a 20-year industrial-grade battery also reduced the total cost of ownership by eliminating future battery replacements.

Application-specific requirements dictate the ideal choice of power supply, with bobbin-type LiSOCL2 cells and industrial-grade Li-ion rechargeable batteries offering design engineers a dynamic range of options that are “truly wireless” by allowing advanced technology to operate entirely off the power grid.

Advertisement

Learn more about Tadiran