Climate change and greenhouse gas emissions, together with the need for renewable energies and a more sustainable future, are pushing the global economy toward electrical mobility. To be successful, electric-vehicle (EV) adoption and other undergoing electrification processes require the availability of more efficient, cost-effective, and safer batteries. Over the last few years, huge efforts and investments have been spent to create next-generation batteries, mainly by focusing on battery chemistry, new chemical formulas, and new materials such as lithium-sulfur and lithium-metal batteries.

Addionics, an Israeli/U.K. startup, has followed a different approach to other companies, focusing on physics instead of on chemistry. Addionics’s chemistry-agnostic approach means that it can still benefit from advances in chemistry while bringing new technologies to battery physics through an innovative physical design of the battery cell. The new battery architecture achieves significant performance improvements across a variety of dimensions without requiring any change in battery chemistry.

“Today’s battery electrodes are manufactured using very thin foil films, similar to regular aluminum foil we use to wrap food,” said Vladimir Yufit, CTO of Addionics. “Their purpose is to collect current from battery-active materials, and this approach has been the same for decades. Our idea was to take this thin foil and make it three-dimensional, with a different design and architecture. The focus of the company is to design these three-dimensional porous metal electrodes, manufacture them, and build batteries based on this advanced technology.”

By taking the existing 2D-layered structure of electrodes and replacing it with an integrated 3D structure, Addionics has developed a technology able to improve battery performance dramatically, reducing cost and charging time, while increasing the battery’s power density and energy. The patented and scalable 3D metal fabrication method minimizes internal resistance and improves mechanical longevity, thermal stability, and other typical limitations and degradation factors that can be found in standard batteries.

Today’s batteries face an energy to power tradeoff: They can store more energy, or they can charge and discharge more quickly. For EV applications, this means there is no battery that can provide long range and fast charging at the same time. Another issue related to current battery technology is the so-called anode-cathode mismatch. The latest advances in lithium-ion battery chemistry encompass the use of silicon in the battery’s anode instead of just pure graphite.

Unfortunately, today’s dominant cathode chemistries are not able to match the high anode energy levels, limiting the introduction of these new technologies. Addionics provides a solution to both of these two key issues by redesigning the cell. Moreover, Addionics technology can be applied to both anodes and cathodes, meaning thicker and higher energy cathodes can be built using advanced architecture. Cathodes with these 3D structures will have higher energy and match the capacity of emerging high-energy anode technologies.

“Our solution takes a physics approach, not chemistry; that means that we can work with almost any kind of battery chemistry and we can adjust our technology to new regulations or new materials,” said Yufit.

Existing battery chemistries can have their performance improved with 3D electrodes, and emerging advanced chemistries can have implementation challenges overcome through 3D structures. Addionics has already demonstrated the advantage of 3D electrodes with various types of chemistries.

Porous metal electrode

Addionics’s basic idea is to make highly porous 3D electrodes that replace the classic metal foils. In this way, it is possible to significantly increase the external surface of the electrodes themselves, with positive results on the functioning of the cells. Having a 3D structure enables better electrolyte transport and, as a result, a lower internal resistance. Figure 1 provides a comparison between conventional battery structure (on the left) and Addionics’s 3D cell design (on the right).

In the conventional battery structure, the active material (black and purple) is coated onto 2D metal foil in the anode and cathode structures, whereas in Addionics’s 3D cell design (3D electrodes), integrated electrodes with active material are embedded inside 3D metal. By moving to 3D electrode designs, batteries can achieve three key performance improvements: increased energy density, lower internal resistance, and safer and longer-lasting performance due to better heat dissipation and higher mechanical stability.

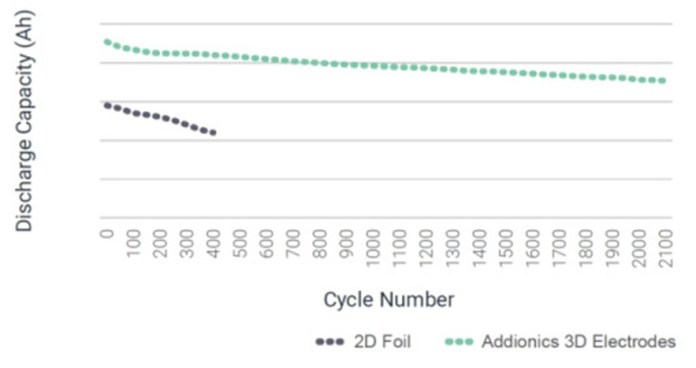

The porous structure invented by Addionics increases performance without affecting the functioning of the electrode, which remains homogeneous and stable even as the power used for charging increases. This means that with a 3D electrode, a lithium-ion battery can last twice as long, recharge faster, and allow for an increase in range in EVs. Figure 2 shows how 3D electrodes can increase the battery lifetime. The first Addionics (green) pouch cell prototype demonstrated more than 2,000 cycles with only 20% capacity degradation, compared with standard cells based on foil (black).

Figure 2: Addionics’s 3D electrode technology has been proven to increase battery lifetime. (Source: Addionics)

Addionics has also developed an innovative approach to manufacturing that not only yields 3D structures at a market-competitive cost but can also lower costs. To optimize the design of the 3D metal structure, Addionics has developed an advanced AI-based battery modelling software that guides the manufacturing process to create optimal structures. Finally, to successfully implement 3D battery structures at scale, new coating processes need to be developed to uniformly coat 3D metal structures.

Addionics has partnerships with big companies to develop batteries, including those working on developing EVs and powertrains. “Our ambitious aim is to get our batteries into every electric vehicle,” said Yufit. “While our technology can be utilized by OEMs, our applications can also be useful in consumer electronics, which can be even more critical since these devices can use fewer and smaller batteries due to very tight space limitations. We are currently focused on improving energy density in three main battery chemistries: silicon, LFP [lithium iron phosphate], and solid-state.”

The article originally published at sister publication Power Electronics News.

Advertisement