By ZACH KILLOY,

Applications Engineer, Power Partners

www.powerpartners-inc.com

In response to the new external power supply efficiency standards, power supply manufacturers are using burst-mode operation to decrease the standby power consumption of external power adaptors. However, burst-mode operation can have adverse, and often unforeseen, effects on RF emissions and end-product compatibility. This article will evaluate these two issues and their possible effects, as well as potential solutions.

As most in the consumer electronics industry are aware, the Department of Energy’s (DOE) new efficiency guidelines for external power supplies went into effect on February 10, 2016. Part of these new efficiency standards take aim at parasitic loads, mandating no-load power consumption for external power supplies (EPS) to be no more than 210 mW in most cases. This is no small feat for power supplies, and in order to meet the new requirements, most power supply designs are using a technique called “Burst-Mode Operation.”

Burst-mode operation is a condition where the power supply control circuit and switching circuit are temporarily disabled when there is no load on the output. Burst-mode operation is a feature contained within many PWM controller ICs used in switched-mode power supplies (SMPS). It works by using the power supply feedback circuit; when there are very low loads on the power supply output, the power supply design allows for a properly biased voltage on the pin that controls burst-mode operation, effectively disabling the power supply for a brief period of time (on the order of milliseconds) until the output voltage sags enough to re-enable the power supply drive. By periodically disabling the main circuits of the power supply at very-low-load or no-load conditions, the power supply is able to consume much less power in order to meet the average no-load power consumption requirement of 210 mW.

The prevalence of ac/dc adaptors has increased significantly over the past 20 years. So many power supplies remain plugged into our electrical grid when not in use that reducing “no-load power consumption” has become an important consideration for reducing overall energy consumption. Think about how many phone chargers, laptop chargers, and tablet chargers you may have plugged in at your home or office: All of these chargers are consuming power and, although the power consumption of an individual charger is low, that parasitic power consumption can add up when all households and offices across the globe are taken into account.

Although burst-mode operation is an innovative approach to limiting no-load power consumption, there are still a number of design implications to consider. Here are two cases in which we have seen burst-mode-operation-related issues:

Case 1: Voltage fluctuation

Recently at Power Partners, one of our customers had several units fail part of their incoming inspection procedure. The units failed the “functional power supply test.” When plugged into the end equipment, the equipment would not turn on. The customer program was in production for some time, and they were placing regular orders without any reported issues. We were eager to see why a number of units out of a single shipment were not passing.

The customer returned several units for evaluation. When we received the returned units, we quickly discovered a potential issue: although the output voltage appeared steady with a DVM, oscilloscope scans showed that the output voltage was fluctuating by about +/−5% around the specified output voltage when the power supplies were unloaded. These power supplies were designed to have burst-mode operation at no load and the output voltage fluctuation was to be expected but, due to component tolerances, the outputs of some earlier shipments may not have fluctuated as much. Sure enough, after speaking with the customer, we realized that their idle load was very low, and they had some under-voltage lockout circuitry in their system that would prevent it from turning on with a low or unclean input voltage.

While the output voltage was still within our +/−5% specification, the unusual waveform caused by burst-mode operation triggered the equipment to enter an under-voltage-lockout condition and remain turned off. Luckily, we were able to adjust our burst-mode setpoint so that our customer did not have to make any changes to their equipment at all. While adjusting the setpoint did increase the no-load power consumption, it remained below the 210-mW requirement and the power supply kept its Level VI rating.

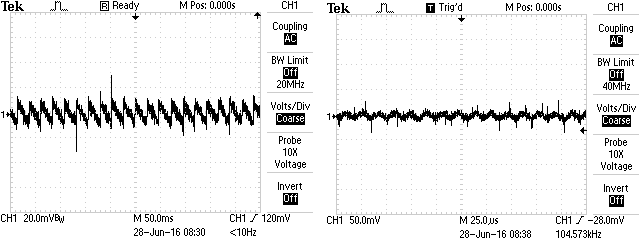

Fig. 1: The output of a 12-V/120-W Level VI-compliant power supply under no load (left Fig. 1a) and loaded to 1 A (right Fig. 1b). The saw-tooth waveform on the left is a result of burst-mode operation. Under load, the output exhibits typical ripple and switching noise. Note differences in frequency.

Case 2: RF emissions

In another example, one of our existing customers was upgrading to a new Level VI-compliant power supply on their latest product redesign. Due to the new product design and new power supply, the system had to be re-evaluated against current safety and electromagnetic compatibility standards for information technology equipment. When the EMC test lab was evaluating the system for electronic emissions, they found that the system exceeded the emissions limits at idle, but passed during normal operation. Power supplies will typically emit the highest levels of electronic emissions at full load, so our initial instinct was to investigate the customer’s equipment and see what had changed. Further evaluation, however, revealed that the customer’s idle load was so low that the power supply was still operating in burst mode. Due to the resonant topology of the power supply, emissions were extremely low in normal operation. In burst mode, things were a bit different.

Although the power supply did pass emissions testing at low load, the pass margin was within a few db. The combination of the power supply emissions and equipment emissions was enough to cause a system-level failure. By investigating how the power supply operates in burst mode, it became more apparent why this was happening.

In burst-mode operation, the switching frequency can be modulated over a large range to maintain the output voltage. This condition persists until the current draw reaches the threshold for the power supply to enter active PWM-mode operation. The changes in the switching frequency at low load and the additional re-energizing of the controller IC and control circuit mean that the EMI filters built into the unit were just not enough to adequately suppress the EMI. The EMI filters were optimized to work on the fixed-switching frequency of the power supply. Again, we were able to adjust the burst-mode setpoint by changing some resistors in the feedback loop and still keep the no-load power consumption within limits.

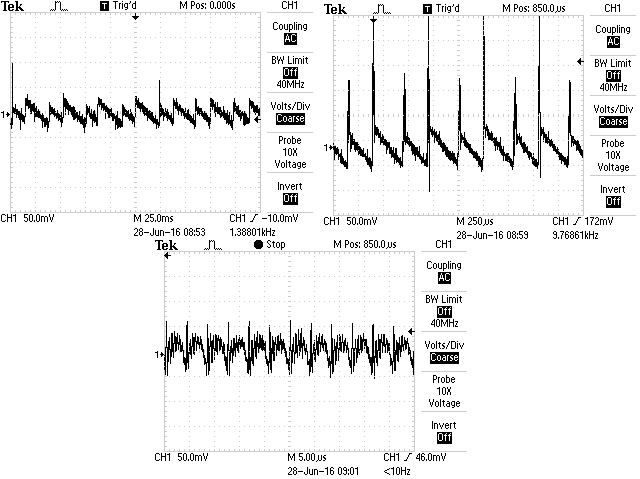

Fig. 2: Burst-mode operation in a resonant topology 12-V/90-W Level VI-compliant power supply. At no load (top left), the output waveform amplitude is low, but when loaded to 500 mA, the pulse frequency and amplitude increases significantly (top right), which can affect equipment and cause increased electronic emissions. With an 800-mA output load (bottom), the unit enters active mode, and output ripple and noise are reduced to normal levels.

With the ever-increasing use of power conversion products in households worldwide, efficiency mandates and the technological advances that make them possible are absolutely essential. However, it is important to consider the ramifications of those efficiency-boosting measures. In both of the cases outlined in this article, the solution was relatively simple and required very little redesign. Going forward, as efficiency requirements increase and power supply circuit technologies become more complex, more measures will need to be considered to mitigate the side effects brought on by these new technologies.

Advertisement

Learn more about Power Partners