By Gary Elinoff, contributing writer

Electronic components that can operate at ambient temperatures of 125° C or above can readily be obtained, which is adequate even for harsh environments, including factory floors or inside motor vehicles. However, that won’t cut it if an application is being built that needs to operate in a truly harsh arena where far higher temperatures are present, such as deep in a mineshaft, in a welding application, or even on-board a satellite in orbit.

Recent work at the Fraunhofer Institute for Microelectronic Circuits and Systems IMS, spearheaded by scientist Dorothee Dietz, has unveiled capacitors that can tolerate temperatures of up to 300° C. A fortuitous side-benefit of the research is that the capacitors produced exhibit lowered leakage current.

New Way To Build Capacitors for High Temperatures

A capacitor is essentially two metallic surfaces separated by a non-conducting dielectric. One of the keys to the Fraunhofer design is that tiny holes have been produced in the two metallic surfaces, increasing the amount of exposed metal while effectively increasing the surface area. This allows for a thicker dielectric, which not only lets the devices withstand the higher temperatures, but also has the effect of lowering the leakage current.

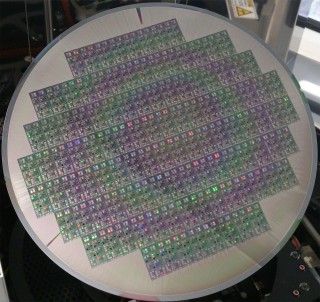

Tiny holes have been produced in both metallic surfaces, increasing the amount of exposed metal. Image source: Fraunhofer.

The new devices are fabricated using the metal-oxide-semiconductor process, which allows for building the layers one atom at a time. Thus, manufacturers have the greatest possible control over thickness, which makes it possible to easily tweak the finished product to anything required by the customer.

The dielectric itself is composed of tantalum pentoxide, a material far better at storing charge carriers than the silicon oxide, which is most commonly employed in capacitors. Because of this, devices built using this type of dielectric, often denoted as High-K dielectrics, can be smaller than conventional units.

The Fraunhofer team also exploited highly conductive silicon and ruthenium in its design. The latter is both tough and heat-resistant, enhancing the practicality of the results.

Beyond Capacitors

The processes developed by Fraunhofer can be readily applied to other passive components including resistors, as well as to active components, such as transistors and diodes. Perhaps even more importantly, this process can be applied not only to discrete components, but also to entire ICs. This will cut down on the need for heat shielding, which is typically expensive, and in some cases, such as in missiles or in satellites, a possible mission-killer. For land-based applications, this opens up the possibility of moving measurement and control electronics right up to where the action is taking place for more direct monitoring and control.

Advertisement

Learn more about Electronic Products Magazine