By Gary Elinoff, contributing writer

Even with recent advances in reusable rocketry, payload weight is and will continue to be a limiting factor in what can be done with space vehicles. So when a material comes along with the promise of delivering the same functionality with 30% less weight, it’s big news, and that’s the case with carbon nanotubes.

Buckminsterfullerenes, or buckyballs, were the first nanocarbons synthesized back in the 20th century. They’re composed purely of carbon, an element that, due to its property of having four valence electrons, can be organized into many unique molecular formats, which can exhibit astounding properties. The possibilities appear to be endless. For example, one form of carbon nanotube has been exploited to form the basis of a new type of computer logic. And, according to NASA, they can exhibit an astonishing 200 times the strength of steel along with five times steel’s elasticity.

Working with the Nanocomp Technologies, Inc’s Miralon sheets, NASA has produced structures that have replaced far-heavier aluminum. The new structures exhibit a coefficient of thermal expansion (CTE) that approaches zero, as well as a tremendous increase in material stiffness. When used to replace conventional cabling, Miralon yarn can provide a weight savings of up to 70%.

According to Nanocomp, the short length of nanotubes previously produced, measured in tens of micrometers, made practical applicability difficult to achieve. The company can now produce nanotubes of over 1 mm in length, which are far easier to exploit to solve real-world engineering problems.

Carbon nanotube-based composites for structural components

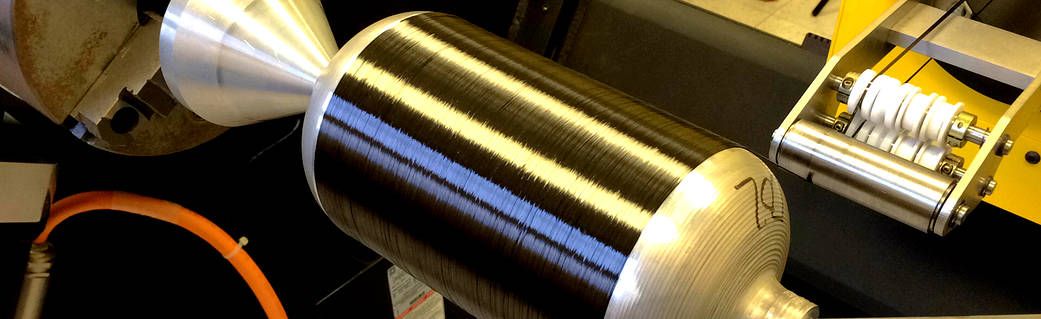

A composite overwrapped pressure vessel (COPV) is a unit consisting of a liner and structural component whose purpose is to contain fluids under pressure. The failure of such a device is believed to be the cause of the failure of the SpaceX Falcon 9 launch of September 1, 2016. In collaboration with Nanocomp, NASA intends to test the first ever COPV to employ a carbon nanotube fiber-based composite tank instead of one built of conventional carbon fiber epoxy composites.

COPV based on carbon nanotube materials. Source: NASA.

The nanotube yarns and sheets are provided by Nanocomp, while NASA has done the actual fabrication of the COPV from the Nanocomp materials. According to NASA’s Emile Siochi, “This COPV represents the first large item that we’ve built” by turning nanotube yarns into composites. “There’s potential for the structural properties of carbon nanotubes to be much stronger than carbon fiber composites, now the state of the art for structural material,” she said.

Mission achieved

The nanotube COPV, along with other new technologies, were tested on the launch of a Black Brant IX sounding rocket as part of the SubTec-7 mission from NASA’s Wallops Flight Facility in Virginia on May 16, 2017. The launch was a success.

Advertisement

Learn more about Electronic Products Magazine