BY TREVOR BARCELO

Design Manager

Battery Management Products

Linear Technology

www.linear.com

Batteries provide power to many different applications across a wide range of industries. In many of these applications, a charging connector is difficult or impossible to use. For example, some products require sealed enclosures to protect sensitive electronics from harsh environments and to allow for convenient cleaning or sterilization. Other products may simply be too small to include a connector, and in products where the battery-powered application includes movement or rotation, then forget about charging with wires. Wireless charging adds value, reliability and robustness in these and other applications.

Wireless power system overview

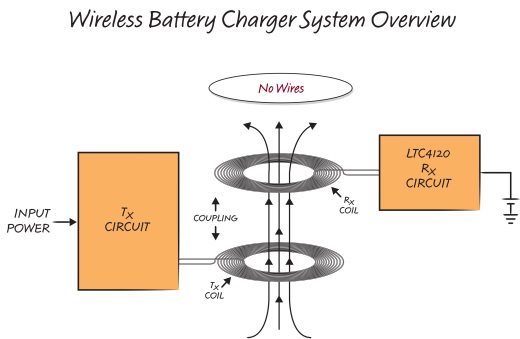

As shown in Fig. 1 , a wireless power system is composed of two parts separated by a gap: transmit circuitry, including a transmit coil, and receive circuitry, including a receive coil. The transmit circuitry generates a high frequency alternating magnetic field around the transmit coil. This magnetic field is coupled to the receive coil and converted to electrical energy, which can be used to charge a battery or power other circuitry.

Fig. 1: Wireless battery charger power system overview.

When designing a wireless power charging system, a key parameter is the amount of charging power that actually adds energy to the battery. This received power depends on many factors, including the amount of power being transmitted, the distance and alignment between the transmit coil and the receive coil, also known as the coupling between the coils, and finally, the tolerance of the transmit and receive components.

The primary goal in any wireless power design is to guarantee delivery of the required power under worst-case power transfer conditions. However, it is equally important to avoid thermal and electrical overstress in the receiver during best-case conditions. This is especially important when output power requirements are low; for example, when the battery is fully charged or nearly fully charged. In such a scenario, available power from the wireless system is high, but demanded power is low. This excess power typically leads to high rectified voltages or a need to dissipate the excess power as heat.

There are several ways to deal with excess power capacity when the demanded receiver power is low. The rectified voltage can be clamped with a power Zener diode or transorb. However, this solution is typically large and generates considerable heat. Assuming no feedback from the receiver, the maximum transmitter power can be reduced, but this will either limit the available received power or it will reduce the transmit distance. It is also possible to communicate received power back to the transmitter and adjust real-time transmit power accordingly. This is the technique used by wireless power standards such as the Wireless Power Consortium Qi standard. However, it is also possible to solve this issue in a compact and efficient manner without resorting to complicated digital communication techniques.

To efficiently manage the power transfer from transmitter to receiver under all conditions, the LTC4120 wireless power receiver integrates technology patented by PowerbyProxi, a Linear Technology partner. PowerbyProxi’s patented dynamic harmonization control, or DHC, technique enables high-efficiency contactless charging without thermal or electrical overstress concerns in the receiver. Using this technology, up to 2 W can be transmitted at a distance of up to 1.2 cm.

By modulating the resonant frequency of the receiver from a “tuned” condition to a “detuned” condition, DHC guarantees delivery of power under worst-case conditions without worrying about unloaded best-case conditions. This allows the LTC4120-based wireless charging system to operate over a wide transmit distance with significant coil misalignment. Furthermore, by controlling power transfer on the receiver-side only, the LTC4120-based system eliminates all potential communication interference issues, which might disrupt power delivery.

System performance

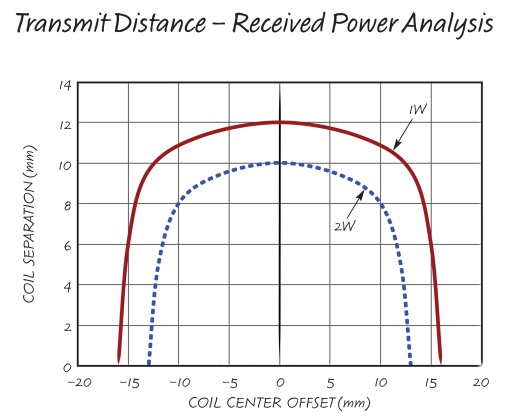

So how well does it work? Figure 2 shows the amount of battery charge power received by an LTC4120 wireless power receiver as the separation and the center-to-center alignment between the transmit coil and receive coil is varied. With 10 mm of separation, 2 W of charge power is available and the coils can be misaligned significantly without much reduction in available power. While many different wireless power transmitters are available, the data in Fig. 2 was generated using a basic dc/ac transmitter. The basic transmitter is an open-source reference design. Additional details for this current-fed push-pull transmitter can be found in an application note on Linear Technology’s website.

Fig. 2: Transmit distance and receive-power analysis.

When choosing a transmitter, several factors should be considered. Is transmitter standby power (when a receiver is not present) important? Does the transmitter need to differentiate between a valid receiver and unrelated foreign metal objects? How sensitive is surrounding circuitry to EMI?

The basic transmitter is a very simple and inexpensive solution. Due to passive resonant filtering, the spectrum of EMI is well controlled at the fundamental transmitter frequency (about 130 kHz). However, it transmits at full power whether an LTC4120-based receiver is present or not. Therefore, its standby power is relatively high. It also does not differentiate between an LTC4120 and foreign metal objects and can cause unrelated metal objects to warm up through induced eddy currents.

Two off-the-shelf production transmitters can be purchased from PowerbyProxi: Proxi-Point and Proxi-2D. Transmit distance and alignment tolerance performance of these transmitters is virtually identical to that of the basic transmitter. However, these more advanced transmitters can detect whether a valid LTC4120-based receiver is present or not. This feature allows them to reduce standby power if no receiver is present and terminate power transmission if unrelated foreign metal objects are nearby.

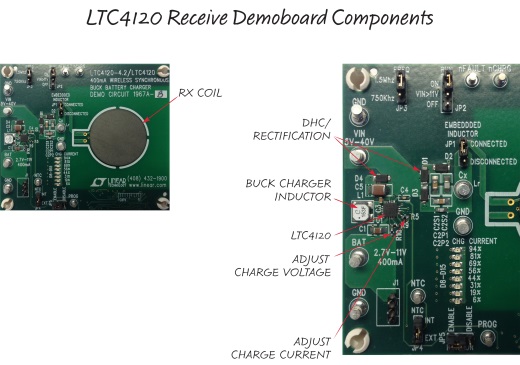

Due to the high-efficiency buck switching topology of the LTC4120 charger as well as the DHC technology, overall system efficiency is about 50 to 55%. To calculate this value, divide the battery charge power by the dc-input power to the transmitter. Overall efficiency is very dependent on coupling and load. When charging a single-cell Li-Ion battery at 400 mA, the components on the LTC4120-based receiver board stay within 10°C of ambient temperature. The LTC4120-based receiver can be seen in Fig. 3 .

Fig. 3: LTC4120 receiver demo board components.

Other system considerations

The LTC4120-based wireless charging system can charge a battery at 400 mA across an impressive gap. Lithium-based rechargeable batteries power many handheld applications and both 1S (nominally 3.7-V) and 2S (nominally 7.4-V) Li-Ion packs are common. Extended cycle life and improved safety features are creating significant market space of LiFePO4 batteries as well. Furthermore, there is a wide variety of target charge voltages within these battery packs as customers fine-tune the trade-offs among initial battery capacity, cycle life, and retained capacity over time. To accommodate this variety, the LTC4120 does not need any additional circuitry to charge one- and two-cell Li-Ion batteries as well as one-, two- and three-cell LiFePO4 batteries. Charge current can be programmed from 50 to 400 mA, while charge voltage can be programmed from 3.5 to 11 V.

In addition to a built-in constant-current / constant-voltage charge algorithm, the LTC4120 includes multiple battery safety features. A termination timer safely ends a charge cycle while an NTC input provides battery temperature monitoring and automatically suspends charging during unsafe temperature conditions. Two charge status pins provide charge cycle and fault status information.

Wireless charging can add value, reliability, and robustness in many different types of applications. The LTC4120 is a key component in a robust contactless charging system.

Advertisement

Learn more about Linear Technology