By Stephen Capitelli

Manager of Product Engineering

Mill-Max Manufacturing Corp.

www.mill-max.com

Connectors play a critical role in just about any product we can imagine, influencing its performance and reliability as a whole. Interconnect requirements, however, are frequently considered only at the end of the product design phase. The impact of an interconnect choice is often made brutally clear only when poorly manufactured or incorrectly specified connectors fail, eroding system performance at a minimum and even bringing the system to a halt. Fortunately for designers, advances in connector design, materials, and manufacturing ensure that an interconnect solution well matched to each individual application is easily available.

The selection of a suitable connector depends on a design’s performance requirements, configuration limitations, operating conditions, and working environment. Thus the connector requirements for a healthcare product are dramatically different from those for a deep-mining application — yet each requires maximum reliability from the connector.

If connector selection is not given proper consideration, the entire application can be left exposed to performance and reliability breakdowns. In fact, today’s innovative connectors are high-precision pieces, carefully designed and manufactured using a variety of high-conductivity alloys, application specific platings and high-temperature, high-strength housing materials.

Manufacturing and materials

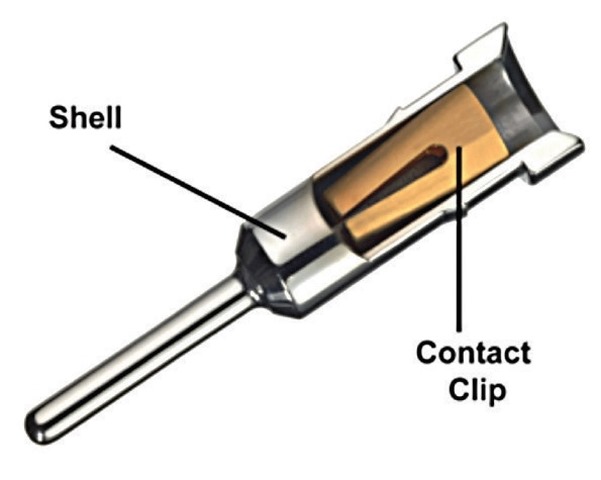

To review the connector selection process, let’s begin by considering one of the main components of connectors and discrete interconnect systems: the pin receptacle. Pin receptacles are made by press-fitting stamped and formed “multifinger” precision contact clips into a machined shell (see fig. 1 ). This style of contact has proven to be an extremely reliable and consistent way to connect critical components.

Fig. 1: Precision pin receptacles combine a precision-machined shell with a contact clip designed to provide a gas-tight connection.

The receptacle itself is a product of precision machining and specialized alloys designed to match specific application requirements. For precision connector lines, high-speed Swiss turning and CNC machining produce parts across a wide range of sizes, while holding very tight diameter tolerances of ±0.0005 in. — and even tighter for some applications! Internal stamped finger contacts provide connections for mating leads ranging in diameter from 0.008 to 0.102 in., as well as square and rectangular pins.

Using advanced machining capabilities, interconnect manufacturers can offer receptacles with many termination styles, including press-fit, solder mount, compliant press-fit, swage mount, and wire termination options including solder cup, crimp, forked, and bifurcated. These same manufacturing capabilities allow creation of specialized receptacles suitable for pressing into plated-through holes in printed circuit boards. Here, polygon press-fit features such as a square, hexagon, pentagon, or octagon are machined on the body or tail of the receptacle — providing stress relief when pressed into the plated through-hole on a PCB. Press-fit features are typically held to a tolerance of ±0.0005 in. to help maintain consistency during the press-fit operation, which is especially important if the application calls for solderless press-fit.

While precision manufacturing allows for a wide range of shapes and sizes, the materials used for interconnect manufacturing endow these parts with specific performance and manufacturability characteristics optimized for different application requirements. In the manufacturing of machined electrical interconnects, a variety of alloys — mainly copper-based due to the need for high conductivity — are used, from highly ductile brass to high-strength beryllium alloys.

Brass is most commonly used, as it exhibits excellent machinability, is suitable for a wide variety of applications, and is cost effective. Phosphor bronze is a more ductile material, useful when additional strength and bending resilience are required. For higher-current applications, tellurium copper’s high conductivity (93% IACS at 68°F) characteristic provides a low-resistance electrical path, producing less temperature rise.

Depending on the desired size and force characteristics, the internal contacts are three-, four-, or six-finger designs stamped from either beryllium copper alloy C17200 (HT) or beryllium nickel alloy 360. Beryllium copper has emerged as the standard for the majority of applications thanks to its excellent strength, spring characteristics, durability, and conductivity. Beryllium nickel exhibits similar properties and is particularly suitable for use in high-temperature environments above 150°C.

Application demands

State-of-the-art connector technology provides options designed to meet specific performance and configuration requirements in applications as diverse as healthcare, LED lighting, and those in rugged environments. More specifically, the combination of a precision machined outer shell and stamped internal finger contact provides the flexibility, quality, and reliability required for mission-critical applications.

In the healthcare industry, for example, high-reliability receptacles are used in multiple places: on detector boards for CT scan equipment; in I/O connectors for portable blood analyzers and implantable devices; for socketing transducers that monitor and regulate vital signs, blood sugar, and other bodily functions; in the signaling circuits for medicine delivery pumps; as the power jack for medical and dental drills and saws; and in cables used on a variety of medical equipment and devices.

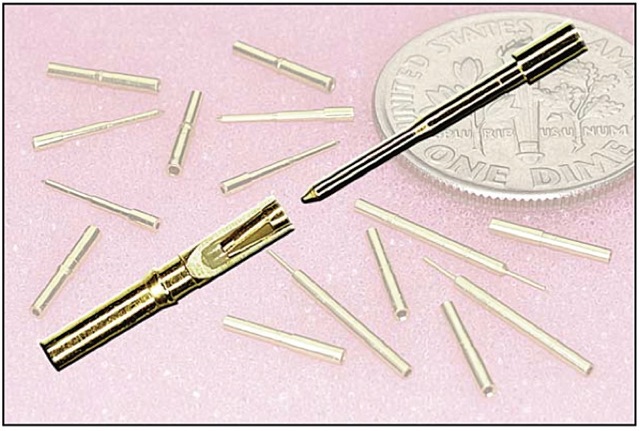

Pins and receptacles are often the building blocks for these interconnect systems. A typical healthcare interconnect application has the need to terminate fine gauge wires to male and female components to make up cable assemblies. One solution, designed and offered by Mill-Max, is accurately machined pins and receptacles featuring wire termination options such as solder cups or crimp barrels. The receptacle is fitted with a high reliability beryllium copper spring contact able to make a secure electrical and mechanical contact to the mating pin. All the components are gold plated to provide protection, durability, and reliability (see fig. 2 ).

Fig. 2: Manufactured using precision turning technology, pin/socket interconnect pairs support high-density grid applications such as the termination of medical cables.

This receptacle design, with a machined shell fitted with a beryllium copper contact, provides a gas-tight connection at the interface of the mating lead and the internal spring contact. This gas-tight connection secures the interface against potential oxide-forming environmental conditions and helps reduce the effects of fretting corrosion that can otherwise occur in these applications.

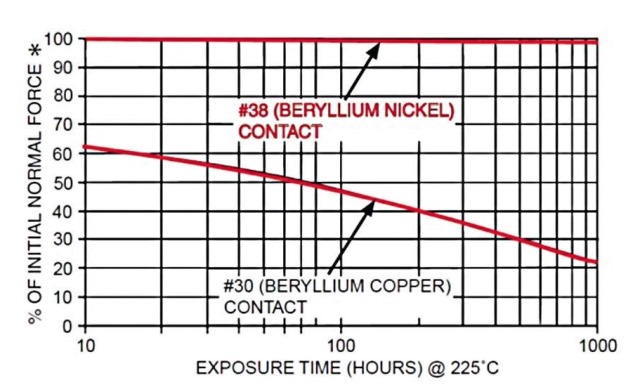

Although beryllium copper is the default material for standard internal spring contacts for receptacles, applications exposed to high temperatures can take advantage of more temperature- and force-resistant materials. For applications such as downhole oil and gas exploration or test and burn-in systems, where the ambient operating temperature is above 150°C, beryllium nickel is the material of choice for contacts. Beryllium nickel exhibits little or no stress relaxation when exposed to 225°C for 1,000 hours (see fig. 3 ). Along with high-temperature performance, beryllium nickel contacts inherently withstand higher forces.

Fig. 3: Beryllium nickel exhibits little or no stress relaxation when subjected to extended exposure to high temperatures — a critical characteristic for applications operating in harsh environments.

Interconnect flexibility

In more advanced interconnect systems, beryllium nickel contacts fit into the same receptacle shell as their beryllium copper counterparts and can be specified as a design evolves from the workbench to the field. In fact, this type of configuration flexibility is increasingly important to designers. With more sophisticated interconnect solutions, engineers can test their interconnect designs, modify interconnect strategies, and even switch to different connector materials and sizes without redesigning the overall interconnect design.

For applications requiring optimal environmental protection or for PCB press-fit applications, gold plated shells and contacts are typically the right choice. If both the outer shell and internal contact are individually plated in interconnect systems, the design engineer has the flexibility to choose tin, tin/lead, gold, or silver plating based on economic and engineering considerations. For example, tin or tin/lead-plated shells with gold-plated internal contacts are a cost-effective option for solder mount receptacles accepting gold-plated mating leads. Despite the different combinations of metals, the gas-tight press-fit between the contact and shell eliminates the chance of oxidizing interactions. This gas-tight connection ensures that no corrosion arises at the contact-shell junction due to environmental conditions such as high humidity or exposure to gases.

In addition, well-designed interconnect platforms can allow designers to change pin sizes by having a wide mating-lead acceptance range built in. While some interconnect systems have a fairly tight lead acceptance range of 0.004 in., enhanced interconnect contacts have a much greater range, generally 0.010 in., with larger contacts enjoying a range up to 0.020 in. in some cases. The wide acceptance range of receptacles translates into greater tolerance on the mating lead size and position — a useful option when a device, mating board, module, or cable undergoes an unexpected change in pin design or specification. Thus, if a piece of equipment is initially designed to receive a cable of a particular size and that cable is revised to use larger or smaller pins, the wider acceptance range available in a versatile receptacle design may easily support the change in specifications.

A flexible interconnect platform also allows engineers to choose higher- or lower-force contacts for most mating lead sizes. Lower forces are desirable for applications such as high-pin-count interconnects; delicate, soft, or flexible leads or wires; socketing leaded-glass-sealed (hermetic) devices; and to ease field replacement and repair in tight spaces. Conversely higher forces are desirable for ruggedized applications facing high shock and vibration, fretting corrosion, high-current connections, and long-term static connections. In addition, higher-force connectors can help overcome oxides caused by environmental conditions, especially advantageous in circuits with low currents.

Advertisement

Learn more about Mill-Max