In space applications, high reliability and risk reduction are always two key considerations. While using commercial-off-the-shelf (COTS) electrical, electronic and electromechanical (EEE) parts may be feasible depending on the space mission profile needs, it is important to understand the tradeoffs.

Unlike COTS parts, space-grade EEE radiation-hardened (rad hard) devices undergo rigorous tests and qualification to ensure reliable performance when exposed to space radiation, especially in long duration, higher orbit or interplanetary missions. In this article, we will look at various mission profiles, radiation and reliability requirements to understand best-fit recommendations for using COTS power devices versus silicon MOSFETs in high-reliability space applications.

Commercial electronics are used successfully in certain space applications, especially where designers can gain higher system performance and lack high-reliability options. However, COTS parts remain fundamentally different than space-qualified ones when it comes to critical aspects like product quality, safety and reliability.

There are inherent risks to using COTS electronics in space, including lack of confidence in parts traceability, wafer lot homogeneity, long-term performance, and reliability. The most critical difference is arguably how and whether COTS parts perform under radiation conditions. Additional screening for radiation assurance may be needed to meet mission requirements, which are highly dependent on such factors as intended application, long-term operating environment, and expected mission lifetime.

In contrast, high reliability space-grade electronics are typically rad hard by design at the semiconductor level. Components undergo 100% parts-level qualification and screening per established industry standards defined by DLA, ESA, and others. Some companies, such as IR HiRel, perform board-level qualification as well. This scrutiny gives a high degree of assurance that these electronics will perform as expected, even under the harshest conditions. Controlled manufacturing processes add another layer of confidence that the electronics will withstand the environmental and application stresses in space.

Important factors when weighing component options include satellite or spacecraft type, mission profiles including expected duration and orbit, and radiation environment. Overall program cost is another key consideration. It can be a fine balance, but reliability ultimately starts with component selection.

Another important thing to note is that reducing risk increases reliability. However, reducing costs entails some level of compromise, whether in quality, reliability, radiation hardness or elsewhere. Bottom line, it comes down to designing architectures that balance mission performance and cost requirements with acceptable risk levels.

Let’s take a look at mission profiles and requirements, along with risk considerations.

Small satellites

Femto/pico/nano satellites

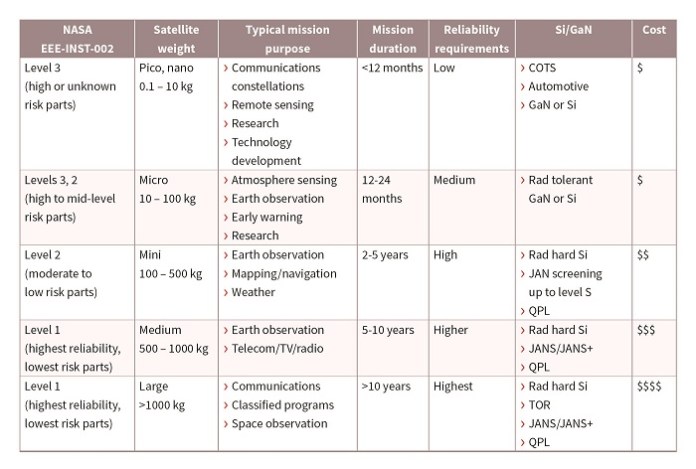

The smallest satellites – femto, pico, nano – usually weigh up to 10 kilograms. Limited in power, size, and often budget, mission duration is typically less than 12 months. Because they can be launched ‘piggyback’ on larger launch vehicles, these satellites have limited orbit capabilities. Typical missions might include constellations for low data rate communications, IoT/M2M, spaceflight systems testing and research.

Reliability and radiation requirements are low for these smallest satellites. In Low Earth Orbit (LEO) at altitudes <650 km, the radiation environment is relatively benign. Using small satellites in constellations or clusters offers a built-in redundancy and regular equipment renewal. While systems might show desired radiation performance, it is not guaranteed, but failure is an acceptable risk.

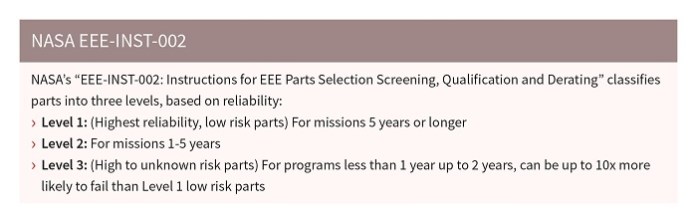

As we will see with all satellites, component selection is driven by part criticality and its impact on system availability. For low-level criticality, designers could use Level 3 parts, COTS or automotive-grade silicon or GaN. With mid-level critical functions, COTS up-screening and testing is recommended. And for highly critical functions, NASA still suggests using what they classify as Level 1 or 2 parts. Note that even to meet Level 3 requirements, NASA’s classification requires additional screening per MIL-STD-883.

Table 1: NASA EEE INST-002: Instructions for EEE parts selection, screening, qualification and derating (Image: IR HiRel)

Microsatellites

Microsatellites generally weigh between 10 to 100 kilograms with a mission duration from 12 to 24 months. Missions might range from atmospheric sensing, Earth observation, early warning or scientific research. Reliability and radiation requirements are higher for microsatellites mostly based on the longer mission duration, although they still may fly in LEO.

In this case, for low to mid-level part criticality, designers could consider COTS or rad-tolerant silicon or GaN components. For high criticality, NASA suggests Level 1 or 2. This could mean full up-screened COTS, fault tolerant designs for COTS or simply using rad-hard parts. Generally, as mission lifetime increases, using rad hard is suggested.

Mini satellites

Moving up in scale, mini satellites weigh anywhere between 100 to 500 kilograms. Typically lasting two to five years, missions may include Earth observation, weather monitoring, navigational or geospatial positioning systems, such as GPS, GLONASS, Beidou or Galileo.

With longer mission durations and higher orbits, reliability and radiation requirements become even greater. For example, over the life of a multi-year mission, total ionizing dose (TID) levels on the order of 105 can easily accumulate. This is why space-grade devices are typically rated in the 100 krad to 1,000 krad range.

For these satellites, moderate to low-risk parts are recommended. Practically speaking, this means:

- Rad-hard silicon with TID screening, design and characterization

- MIL-PRF-19500 JAN screening up to quality level S

- QPL for both active and passive parts

- NASA EEE-INST-002 Level 2 to Level 1 moderate to lowest risk parts

Medium-sized satellites

Members of this satellite class weigh between 500 to 1000 kilograms and have mission lifetimes of five to ten years. Typical missions include Earth observation and telecom/TV/radio communications. Based on expected mission duration and orbit, reliability and radiation requirements are even higher.

- For mid-sized satellites, recommended components include:

- Rad hard silicon with TID screening, design and characterization

- MIL-PRF-19500 JAN screening up to quality level S

- QPL for both active and passive parts

- NASA EEE-INST-002 Level 1 highest reliability, lowest risk parts

Large satellites and spacecraft

This class generally includes anything over 1000 kilograms. Missions may last for ten or more years. Orbits are usually higher and may include communications, space observation, classified government initiatives, as well as spacecraft for interplanetary or deep space travel. Unsurprisingly, this class has the highest reliability and radiation requirements.

One exception to the higher orbit rule of thumb is the International Space Station (ISS), which operates in LEO. ISS supports human life and has done so continuously for more than 20 years. Based on these factors, it also requires the highest reliability and radiation levels for its continued mission success.

For these large satellites and spacecraft, recommended components include:

- Rad-hard silicon with TID screening, design, and characterization

- MIL-PRF-19500 JAN screening up to quality level S, including radiation hardness assurance (RHA) levels

- QPL for both active and passive parts

- Aerospace Technical Operating Report (TOR)[1] compliance

- NASA EEE-INST-002 Level 1 highest reliability, lowest risk parts

Table 2: Best-fit recommendations vis-à-vis mission profiles, duration and reliability requirements according to NASA EEE-INST-002 (Image: IR HiRel)

Conclusion

Clearly, the end application drives the qualification, radiation, and reliability requirements. As we’ve seen, there can be vast differences in mission profiles, expected lifetimes, orbit and radiation exposure, all of which factor into the reliability-risk calculus.

Given the unique constraints in space – environmental hazards, limited servicing options, variability of mission lifetimes and orbits, requirements for function criticality and system availability – both COTS and space-grade components will certainly continue to play key roles. However, currently only rad-hard silicon meets QPL, JANS and Aerospace TOR requirements for missions where “significant risk of failure, or the inability to quantify risk or confidence” is unacceptable. As an industry, we will no doubt continue to focus on advancing technologies, platforms, packaging and more to deliver radiation hardened solutions that bolster confidence from the component through system- and mission-level.

[1] Space programs may be subject to report number TOR-2006(8583)-2336 REV B, dated March 6, 2013, entitled “Technical Requirements for Electronics Parts, Materials, and Processes Used in Space Vehicles,” or “TOR,” published by The Aerospace Corporation. TOR specifies quality requirements above and beyond the applicable MIL-PRF standards.

About the author:

Paul Hebert is the director of quality management for IR HiRel Products, an Infineon Technologies company. Paul has over 30 years of experience in failure analysis, reliability and quality management for high reliability electronics, particularly microcircuits and semiconductors. A major focus has been zero defects via the adoption of robust processes, designs and systems for high reliability products. Mr. Hebert holds an MBA from Babson College.

Paul Hebert is the director of quality management for IR HiRel Products, an Infineon Technologies company. Paul has over 30 years of experience in failure analysis, reliability and quality management for high reliability electronics, particularly microcircuits and semiconductors. A major focus has been zero defects via the adoption of robust processes, designs and systems for high reliability products. Mr. Hebert holds an MBA from Babson College.

Advertisement

Learn more about Infineon Technologies