By David Johnson,

Technical Market Analyst, Bourns,

www.bourns.com

The Internet of Things (IoT) is actively progressing toward the goal to connect billions of smart devices into intelligent systems, giving users actionable real-time data that enables improved decision-making. For example, in the industrial automation market, smart and connected equipment can be deployed that monitors machines on the factory floor. By checking for failure or error messages, IoT systems allow operators to proactively manage issues to eliminate unplanned factory downtime that can lead to reduced revenues. Therefore, making IoT a reality calls for applications to be developed that maximize network efficiency, interoperability, and security. Along with low-cost, high-speed communications technologies, smart sensors, and data analytics, circuit protection also plays an essential role. The more devices are connected, the more opportunity there is for system failure that can be a serious threat for always-on smart devices.

This article presents the increasingly integrated devices that comprise the IoT ecosystem and will require proven circuit protection solutions to maintain the system reliability expected of the IoT infrastructure.

IoT ecosystem devices

IoT is not relegated to a single sector or market; it is a trend that has the power to affect all global markets and improve every aspect of people’s lives. It goes beyond what we typically think of as communication devices and can include white goods, wearable fitness devices, smart home devices, medical diagnostic equipment, and so much more. Almost any machine can be transformed from a standalone device into a smarter, more connected system (see Fig. 1 ).

Fig. 1: IoT is expected to affect all global markets and include devices like washing machines, smart home devices, and industrial automation equipment.

Various electronic devices will make up the billions of connected devices streaming information that can be used to make decisions. Sensors are used to communicate with a local hub, a central location, or a server; software analyzes the data received and either makes a decision based on programmed logic or notifies an operator to initiate some action. For example, IoT is expected to be optimized for automation to monitor individual machines and provide failure or error messages, allowing field maintenance the opportunity to alleviate the issue and thus eliminating unplanned factory downtime that can lead to reduced revenues. IoT-ready equipment can be used to detect imminent malfunction by monitoring temperature or vibration in a motor and notifying maintenance prior to catastrophic failure.

Network efficiency, interoperability, and security are also an IoT mandate, so data communication devices are also needed that include networking equipment, servers, and “Software as a Service” (SaaS). The following device types are needed in the IoT ecosystem:

- End Points — Comprised of environmental, physical property, position, or chemical sensors that act as the data collection point for the information to be analyzed. These are the components responsible for monitoring systems for changes, as well as providing the prompt feedback used to make adjustments that keep systems performing at optimal levels.

- Gateways — Provide a range of data-aggregation functions and real-time analysis to and from an IP network. They also support reliable publish/subscribe mechanisms and provide IoT data buffering in situations in which the cloud is temporarily unavailable.

- Hubs — Communications gateways such as switches, routers, or modems that facilitate connectivity. Simple hubs connect end points to broader networks and, by integrating hubs, can be connected with the outside world via the internet. They are designed to work together to provide a diverse array of services that fit together seamlessly.

- Network Infrastructure — Used to bring together data from gateways and enterprise sources. Infrastructure manages and monitors devices and services information, transforming it into actionable intelligence. Reliability is an important concern to keep the network infrastructure running smoothly.

- Network and Cloud Services — The IoT is all about communication. Data communication moves via LAN or WAN technology from hubs to servers; systems can function either locally or remotely and may be wired or wireless.

- Enhanced Services — Big Data initiatives, analytical software, and data servers or cloud storage are some of the enhanced services enabled by an IoT framework. Offering the greatest business value, information must be collected in real-time and analyzed for company performance, equipment maintenance requirements, product preferences, and a range of new interactive services.

Why circuit protection matters

More connected devices increase the chance of system failure, which is certainly not an option in maintaining the highest reliability for always-on smart devices. A smart grid or intelligent transportation application, for instance, must perform with extreme reliability and remove the threat of data tampering. Furthermore, many devices are located in remote areas, outdoors, in public settings, or perhaps worn by individuals. Transients such as lightning, burst, or electrostatic discharge (ESD) are a constant threat to devices in these situations. Therefore, IoT-optimized systems need to be designed with advanced surge and circuit protection to ensure that sensitive circuits operate reliably.

It is estimated that the broad adoption of IoT will correlate to the growing need for circuit protection technologies. Technavio, an independent tech-focused global research firm, predicts that the global circuit protection market will grow 5.49% CAGR from 2014 to 2019 based on the rising demand for electricity that is predicted to align with an increase in IoT deployments.

Circuit protection solutions include a range of devices, including rugged SPD (Surge Protection Device) modules for harsh computing environments and customized magnetics and trimmers that support efficient power management. An example is Bourns MultiFuse products designed to help avoid catastrophic failure by monitoring and managing overheating inside motors and pumps. Transient Blocking Unit devices offer a low conductive in-circuit protection device. As IoT systems continue to proliferate, systems integrated with these circuit protection technologies increase reliability while reducing bill of materials (BoM) costs (see Fig. 2 ).

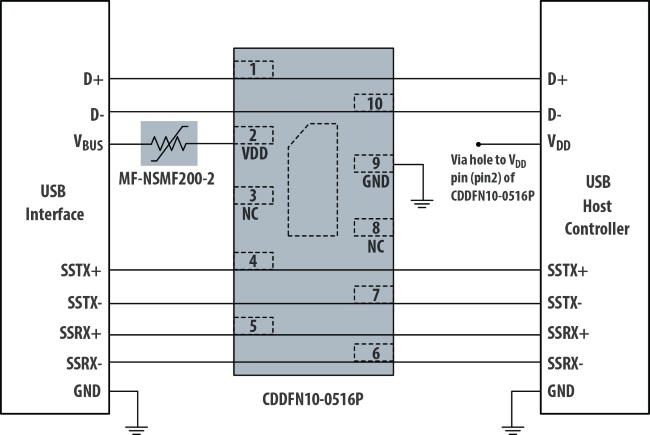

Fig. 2: This example schematic of protection for the USB interface is just one of many IoT-based applications that will need to be handled by a range of in-circuit protection solutions, such as position sensors and magnetic and trimming potentiometers.

Another IoT need will be to support mobile device users that employ touchscreens and other interfaces, such as push buttons, switches, or connectors that can create ESD events. Protecting against ESD failure requires protection devices, such as ESD suppressors or TVS diodes. When the device supports higher throughput in the gigabit-per-second range, ESD protection requires smaller device capacitance and faster response times. For example, new ESD protection devices are available that provide sub-picofarad channel capacitance and nanosecond response times.

IoT adoption and growth

Combining the explosion of low-cost, high-speed communications technologies, smart sensors, and data analytics with the ability to ensure higher device reliability with advanced circuit protection technologies is the foundation that IoT needs to ensure its future successful adoption and growth. The number of IoT connections is expected to continue its exponential growth rate. New communication protocols and system architectures will support the bandwidth and computing performance needed to continue growth. “Smart sensors” will fuel data collection and dissemination through integration and communications. Analyzing IoT-provided data provides the essential information to improve production capabilities, reduce energy consumption, and enhance multiple business processes.

For OEMs working to fulfill the IoT promise, circuit protection needs to be a high priority early in the design cycle. With efficient circuit protection, one worry of system reliability in a connected work is removed. The good news is that system designers have a broad selection of proven and advanced circuit protection solutions readily available as key IoT enablers for the reliable delivery of useful information anytime and anywhere.

Advertisement

Learn more about Bourns