BY ELLEN BLINKA, Product Marketing Engineer,

Texas Instruments

www.ti.com

Sophisticated automation systems are necessary in today’s hyper-competitive global market to ensure production efficiency while maintaining the highest quality standards. Even manufacturers in regions with low labor costs are eager to increase the sophistication of their automation systems because they know that failing to do so will jeopardize their position in the global economy.

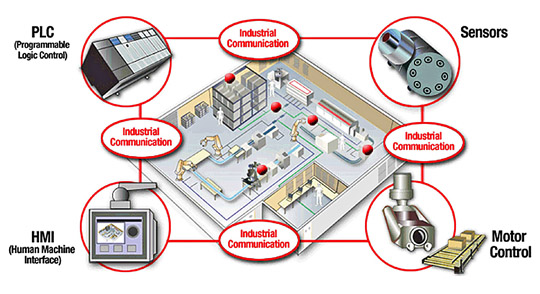

The heart of the latest industrial automation system is a new generation of advanced intelligent sensors connected via low-latency real-time networks to programmable logic controllers (PLCs) and human machine interfaces (HMIs). Of course, time is money for manufacturers, and an efficient production line will run as fast as possible as long as the product manufactured achieves an acceptable level of quality. To achieve efficiency, reliable sensors must monitor conditions on the production line very quickly — in milliseconds or less. Instead of using typical Ethernet, specialized industrial Ethernet communication protocols are used to link sensors to PLCs or other equipment. While typical Ethernet has no guaranteed delivery times or set cycle times for messages, these protocols can achieve the low-latency deterministic response required. These industrial Ethernet protocols are also critical for processing elements, such as PLCs, which must respond in real time with the right course of action or the production rate will suffer.

The basic challenges facing industrial automation haven’t changed: reliability, accuracy, and ease of use. Developments in networking and other connectivity technologies are essential for meeting the challenges of delivering continuous improvements. In the industrial automation marketplace, there are currently more than 120 serial communication standards and upwards of 50 Ethernet-based protocols that can be deployed. The problem isn’t a lack of solutions, but rather having a lot of solution options and deciding how they need to be deployed.

Keeping it as simple as possible

Implementing an industrial automation system with elements from several vendors can require deploying several different communication protocols. It may seem logical to use only one vendor for equipment in the factory or ensure that all equipment chosen for a factory’s automation system works with the same communication protocol, but this is extremely difficult to achieve in practice. Factory automation architectures can be extremely complex, and as the needs for replacements or updates come up at different times for different equipment, replacements may not be available with a certain protocol supported or the best solution within budget may force the automation system to include another new protocol.

For these reasons, it is common to have a factory automation system that needs to support multiple industrial networking protocols. This adds to the complexity of the overall system and can significantly drive up costs. Overcoming the challenges will require advanced flexible technology that can implement multi-protocol communications, with on-the-fly protocol sensing in order to detect what protocol is being used and then switch to that protocol during run time. This kind of auto-detection function will eliminate some of the complex architecture problems that factory engineers are commonly faced with today.

In order to meet global demand for manufactured products and processed materials, industrial automation systems must continue to improve in speed, accuracy, reliability, and precision. These motivations lead to trends like Industry 4.0, which will further complicate the challenges of connectivity in factory automation systems. The Industry 4.0 trend pushes manufacturers to incorporate more sensors and to have these sensors connect seamlessly to factory automation networks and to the cloud.

Manufacturing companies of all sizes strive to tightly couple their production systems with their other enterprise business systems, including supply-chain and demand-monitoring systems. As a result, the communication protocol environment will become even more heterogeneous, accentuating the importance of multi-protocol support for factory automation systems, and the connection to business systems in the enterprise will introduce another layer of complexity to the communication systems.

Gateways aid connections

Communication gateways will become more critical since they will be able to aggregate data from a large number of sensors and feed it to the cloud and to enterprise systems for visualization of the entire factory’s status. Communication protocols, such as OPC UA, are already being adopted in embedded systems, such as these communication gateways, in order to seamlessly connect control-level factory equipment with servers running the enterprise systems. This all adds to the complexity of the network. Automation equipment with multi-protocol support and protocol auto-detection can alleviate some of the network design challenges.

To address these needs, designers of industrial automation systems are looking for complete, cost-effective solutions for embedded processors, analog components, software building blocks, and support tools. One example of such a design package could use TI’s Sitara processors based on ARM Cortex-A8 and -A9 cores with a real-time communications accelerator for multi-protocol processing — the programmable real-time unit (PRU). This solution set offers real-time and high-level operating systems, graphics processing, and other resources.

The goal for manufacturers of all sizes is to be nimble, agile, and exceedingly efficient producers of products and processed materials. Leading-edge multi-protocol technology can help to ensure that industrial automation vendors have the capabilities they need to meet the needs of the marketplace.

Advertisement

Learn more about Texas Instruments