BY JULIA PALU

Vice-President

VARTA Microbattery

Data integrity and high availability are two critical requirements of servers used in enterprise computing environments such as data centers and server farms. Government, financial, IT, and other institutions depend on server arrays to be up and running continuously, and to be quickly restarted after any unplanned shut-down. It is also essential that all data be stored without risk of loss.

The RAID (Redundant Array of Independent Disks) architecture adopted by system administrators is an important component of the measures taken to provide for reliable data storage. RAID systems distribute data across multiple disk drives, with techniques applied to ensure that if one disk fails, the data can be recovered from the others. When using a RAID system, a disk failure does not result in the loss of user data.

But the RAID architecture does not protect against loss of data in the event of an unplanned power outage. And here, as will be discussed, system design engineers are battling a number of problems with the backup power sources commonly used in emergency data storage. This article shows that new developments to an often overlooked battery technology can provide a reliable and attractive way to eliminate these problems.

Backup battery: a changed function

Since server processors run thousands of times faster than the disk drives attached to them, RAID controllers use a small amount of fast DRAM to hold data in cache memory until it can be written to the disk drives. Disk-drive memory is nonvolatile: Data is stored even when the device is powered off. Volatile DRAM, however, requires a backup power source to preserve data in the event of a power outage.

Older server architectures provided a backup battery to keep the DRAM cache powered in the event of a main power outage for periods of up to 72 hours, to give system administrators enough time to restart power. The requirement here was for a battery with relatively high capacity, supplying a low and stable current for a sustained period.

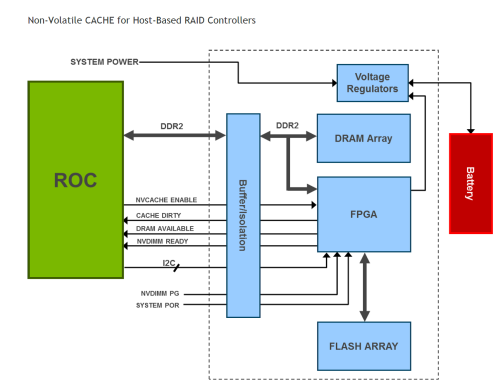

With the development of ever cheaper and denser flash memory devices, however, a new architecture has been adopted: today’s servers are designed to transfer in-flight data held in the DRAM to a nonvolatile flash memory array for protection if the main power unexpectedly fails (see Fig. 1 ).

Often known as flash-backed write cache (FBWC) or battery-backed write cache (BBWC), this memory backup is required to enable RAID controllers to perform operations such as write-back cache, array expansion, logical drive extension and strip size migration. The FBWC cache module typically consists of an FPGA, DRAM devices and NAND flash. When system power is lost, the FPGA takes over from the RAID controller and moves data from the DRAMs to flash. The data is stored securely in flash until the main power supply returns, when the FPGA can restore the cache, moving data from flash back to the DRAMs.

Fig. 1: typical architecture of a nonvolatile cache memory system in RAID controllers. (Source: Dell).

This means that the backup power source now has a different requirement: to supply a burst of high current lasting for a few minutes at most, since the DRAM can be allowed to power down and lose its data once it has been safely copied to flash. Normally a power input from 5 to 10 W for 15 to 30 s is required for every gigabyte of data to be saved to flash.

Backup power approaches its limits

To date, server design engineers have chosen one of three backup power solutions for this application.

• Lithium-ion cells are notable for their high energy density, providing a high capacity in a small pack when new.

• Supercapacitors have a lower energy density, but have tended to be chosen for FBWC applications because of their high current output capability, since flash writing operations call for high peak current.

• Nickel metal hydride (NiMH) batteries are highly regarded for their robustness and reliability, but are often seen as outdated in comparison to lithium battery types

The conditions, in which FBWC circuits must operate, however, are becoming more demanding – and the trend in server design is now pushing both lithium batteries and supercaps beyond the limits of their operating capabilities. Why is this? The two main pressures on backup power sources are linked. First, servers are handling ever greater volumes of data, which means that cache sizes increase from one generation of server to another, which in turn means that the flash backup capacity needs to grow. It means that the FBWC system must be capable of writing ever more data to flash in the event of a power outage. This takes longer and requires more power, which means that the capacity of the backup power source needs to rise.

At the same time, the space available on the board is no greater than before: processors, memories and other devices are doing more work in the same space, and the inevitable consequence is that more heat is generated at the surface of the board. Where once components on a server board might have been specified for operation at a maximum ambient temperature of 45°C, that has risen in recent years past 55°C to a typical value today of over 60°C. Server manufacturers are expecting to design for an ambient temperature of 65°C in the foreseeable future. And this is the reason that users of lithium-ion batteries and supercaps in FBWC applications find themselves between a rock and a hard place.

On the one hand, they need higher energy capacity without taking up more board space, while specifying operation at ambient temperatures above 60°C.

On the other hand, both lithium-ion batteries and super-capacitors suffer from degradation and partial or total loss of performance at high operating temperatures.

Conventional lithium-ion cells cannot be operated permanently at temperatures close to and above 60°C at a high state of charge for both stability and safety reasons. It is true that LCO (Lithium Cobalt Oxide), graphite and LiPF6 (Lithium hexafluorophosphate electrolyte solution) batteries can tolerate multiple charge/discharge cycles at 60°C. The memory backup application, however, entails stand-by operation at permanent high temperature, not frequent charge/discharge cycles. In these conditions, the system designer cannot guarantee a full 3-year lifetime unless the capacity is significantly over-specified. What makes this problem worse is that lithium-ion batteries cannot be charged at temperatures above 45°C. While leakage current gradually drains the battery, the system cannot replenish it if the server operates hot 24/7/365. On top of this, the developer is faced with the additional task of designing protection circuitry to ensure that charging can be started only when the temperature has fallen below 45°C.

Overspecifying the battery clearly imposes a size and cost penalty; it also exposes the system to the risk that insufficient capacity will be available one, two or three years into the server’s operating life, since the rate of decline in battery capacity is dependent on the usage profile and on operating conditions.

Planned maintenance – periodic replacement of the battery – is a solution to this problem, but a highly undesirable one, since it involves the use of costly field technicians.

As ambient temperature specifications for server boards have risen above 60°C, users of super-capacitors have run into the same type of problem: rapid reduction in capacitance over time due to degradation of the materials in the device, drastically shortening its operating life.

Since reliability and high availability are critical parameters of server performance, the risk of premature failure counts strongly against the use of supercaps. On top of that, the designer faces other challenges in their use, including the need for extra circuitry to implement cell balancing and protection against over-voltage damage while charging. And of course supercaps are a low energy-density technology, so meeting the rising energy capacity requirements of next-generation servers calls for the use of ever larger devices.

Supercaps even pose problems at the end of their useful life: the acetonitrile (nonaqueous) electrolyte used in most supercaps is classed as a hazardous waste (due to toxicity and ignitability) according to US federal regulations, and specific disposal arrangements are required for it.

It is also dangerous when burned – decomposition products may be released such as:

• hydrogen cyanide (hydrocyanic acid)

• carbon dioxide

• carbon monoxide

• oxides of nitrogen

• dense black smoke

Hazardous reactions can also occur when materials in supercaps burn, producing toxic gases such as alumina, oxides of nitrogen, carbon dioxide, cyanide and boron fluoride.

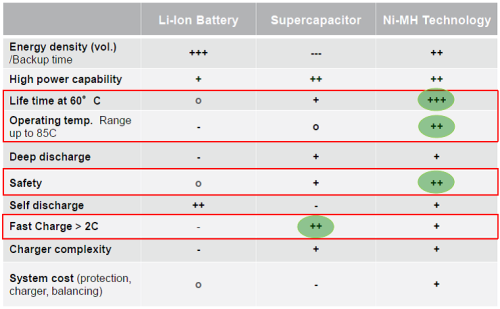

The characteristics of lithium battery types and supercaps are compared in Fig. 2. This table also lists the key features of nickel metal-hydride (NiMH) cells. NiMH is a mature battery technology. In the minds of many design engineers, it might appear outdated, superseded by lithium battery types, which offer a higher energy density and are thus better suited to space-constrained – and highly familiar – end products such as laptops and mobile phones.

Fig. 2: comparison of key features of server backup power sources.

But while lithium-ion has been grabbing the attention of the technology world, quietly in the background cell manufacturers have been continuing to develop the NiMH chemistry. One of the most interesting and useful breakthroughs is in the adaptation of NiMH for high-temperature applications requiring high discharge power.

High-temperature NiMH far exceeds the temperature tolerance of li-ion batteries and supercaps: it has an operating temperature up to +85°C for discharging; it can be continuously charged at up to 70°C. Life expectancy at high temperature is rated at more than five years.

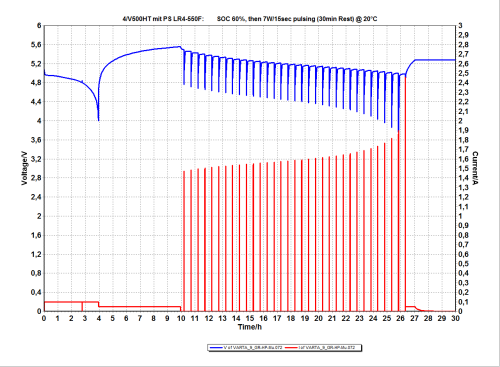

For designers of FBWC circuits, this high-temperature tolerance is extremely valuable. NiMH is a reasonably dense chemistry, and the required capacity can be provided in a small form-factor package – typically one-tenth the size of a supercap solution offering equivalent capacitance. NiMH is well known for its tolerance of over-charging: the design of charging circuitry for maintaining a constant high state of charge is extremely simple. And this means that the designer eliminates the risk that there will be insufficient capacity in the backup power source to drive a complete flash-write cycle should the system suffer power failure (see Fig. 3 ).

Fig. 3: at a state of charge of 60%, a V500HT cell can power 32 flash write operations each requiring an output of 7 W for 15 s.

In addition, the electrolyte in NiMH cells is KOH (potassium hydroxide): aqueous, not flammable, it has a very high boiling point of 110°C, compared to 82°C for acetonitrile. This results in higher thermal stability and a longer life span at high temperatures, because the rate of internal degradation in NiMH is far slower. In fact, NiMHachieves the highest safety of any passive power-storage technology, while avoiding the need for the complex protection and charging circuitry used with lithium and supercap solutions.

At the same time, NiMH-chemistry batteries are easy to dispose of. NiMH is classified by the federal government as a nonhazardous waste, and NiMH batteries are safe for disposal in the normal municipal stream. Check local state disposal regulations for specific implementation.

As well as tolerating stand-by operation for long periods at high temperature, the FBWC application must also provide high peak output current. The latest NiMH technology is suitable here as well.

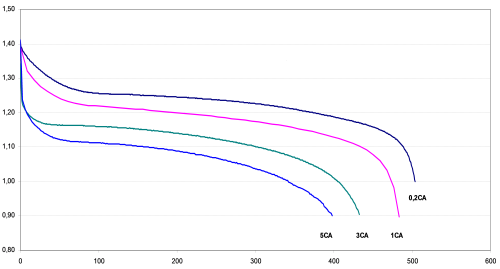

The V500HT from VARTA Microbattery, for instance – a cell optimized for high-temperature applications such as server backup supplies – features an innovative electrode structure that results in a much lower ESR than is commonly found in NiMH cells This enables it to produce peak power output up to up to 20 CA (1 CA is the nominal capacity expressed in amperes), comfortably high enough to drive the write operations of today’s dense flash memories (see Fig. 4 ). It can also be fast-charged at up to 7 CA.

Fig. 4: discharge characteristics of V500HT NiMH cell.

V500HT: high peak power, long shelf life

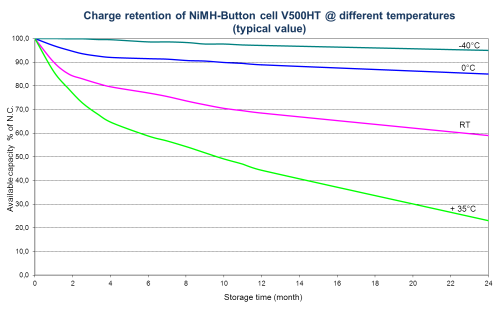

Design engineers who used NiMH cylindrical cells many years ago may recall the NiMH’s chemistry’s short shelf-life and low peak-power output. These characteristics are not found in the latest NiMH batteries. The new cell used in the V500HT dramatically improves shelf life (see Fig. 5 ). The V500HT is shipped at a state of charge of 95% (approximately 475 mAh). After two years’ storage at room temperature, the remaining capacity is >50% of nominal capacity, >250 mAh. If the module is assembled on the board and subject to a typical 10-µA leakage current, it can still be on the shelf for another 2.85 years (a total of almost 5 years on the shelf) before it is fully depleted, and it can be stored even longer without significant degradation.

Unlike lithium battery types, NiMH technology recovers nearly all its capacity after slowing discharging down to 0 V, and the battery can be charged back up to more than 95% of its initial capacity. In general terms, as well, the performance of the V500HT is extremely reliable, with recorded failure rates trending at a figure of less than 5 parts-per-million.

Fig. 5: V500HT, charge retention profile at various storage temperatures.

In fact, while lithium batteries have gained a reputation among electronics designers generally as the most advanced battery technology available today, the latest NiMH batteries deserve more kudos than they currently enjoy: Small and thin, they are capable of storing high energy and power in a small space, and delivering it at high current. Yet they are capable of performing this remarkable feat while posing no risk to the user, since they do not overheat during charging, and provide stable, reliable performance typically for more than five years. In short, it is high time for electronics system engineers to re-evaluate this already excellent, and now improved, technology.

Fig. 6: a typical server cache backup battery pack using VARTA Microbattery’s V500HT cell.

Advertisement

Learn more about Varta Batteries