By Rich Quinnell, editor, Special Projects

Key components of modern industrial systems are the sensors that feed data to the controllers, monitors, and other operational technologies running the plant. Networking of sensors has been in use for years, but the advent of the internet has expanded both the opportunities and challenges of using sensor systems. The design opportunities and challenges have also expanded as sensors become part of the industrial internet of things (IIoT).

Sensors play a variety of roles in the modern factory. In addition to providing data for process control, they assist in quality assessment, asset tracking, and even worker safety. The advent of powerful, cloud-based analytical software and artificial intelligence has also allowed the use of sensor data to lower production costs through process optimization and predictive maintenance. And once routed to the internet, sensor data can be put to a variety of uses from supply management to global coordination of production resources.

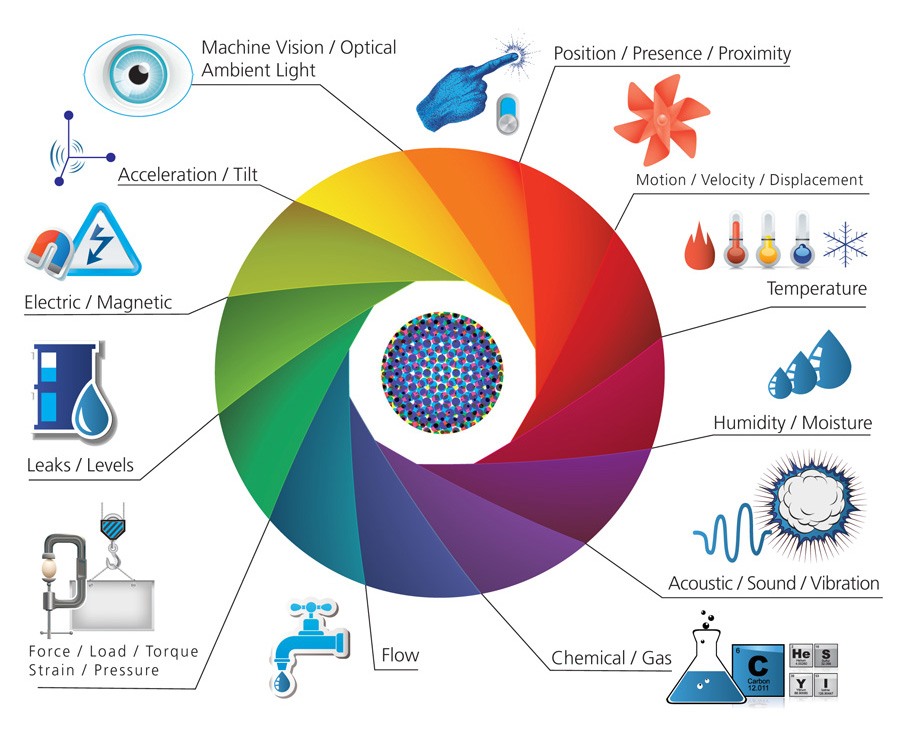

To serve these many purposes, there is a wide variety of sensor types available, with new and improved versions coming along continually. Illumination, temperature, motion, position, presence, vision, force, flow, and chemical composition are among the most common sensor types. Virtually every type of process or environmental condition has a sensor type suited to its measurement, available from broad portfolio companies like TE Connectivity and specialized providers like Aceinna.

There is a wide variety of sensor types used in the industry that need connection to the IoT. (Image: Postscapes)

Traditionally, the information that this multitude of sensor types provides has remained a local resource, confined to a single facility or even a single machine. The advent of low-cost, wide-area connectivity options, however, has opened the door for access to sensor data from anywhere on the globe. This accessibility has unlocked a huge array of options for utilizing sensor data and information. One that sparked immediate and widespread interest is predictive maintenance, wherein remote computers (somewhere in the cloud) running powerful analytical algorithms use sensor data to determine the health of machinery in near-real time to identify urgent maintenance needs before equipment fails. But many other applications are being identified for leveraging the ability to connect individual industrial sensors to all of the resources and stakeholders of the world.

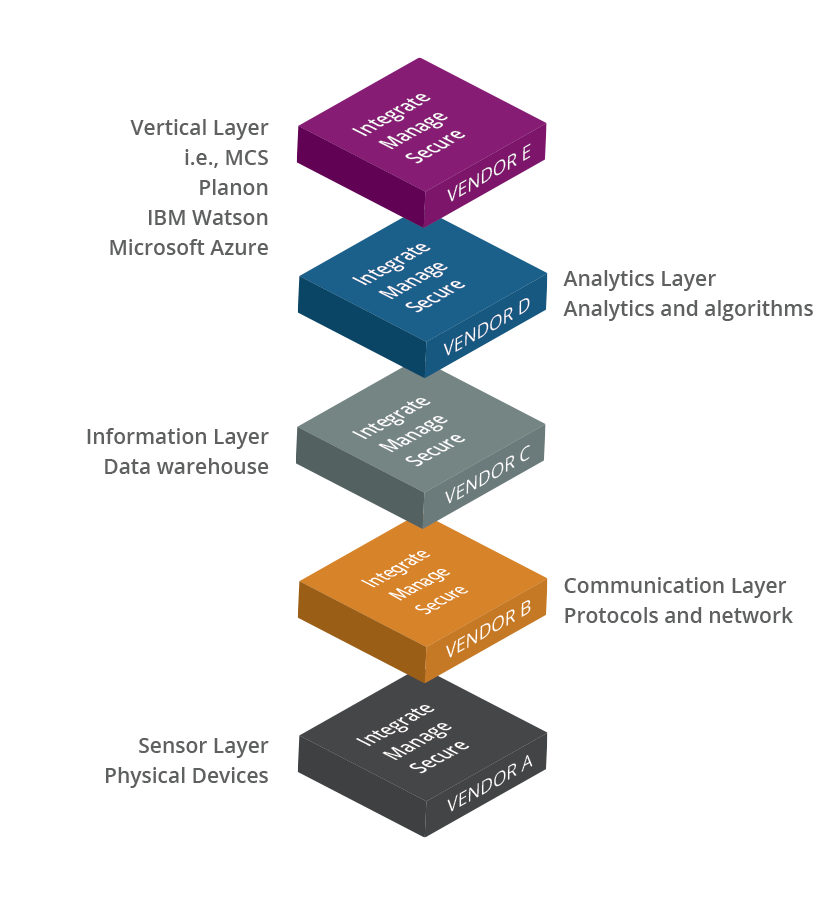

Unfortunately, it’s not especially easy to connect a sensor to the internet and do something useful with the data, especially if dealing with legacy sensor systems. Industrial sensors use a variety of protocols for sending their data to their traditional users. The internet, however, requires data in the TCP/IP format, so there is at least a protocol conversion required. A hub or gateway may be needed to consolidate and concentrate the data, especially if many sensors need connectivity. And the data must have a destination, which means using a cloud service of some kind to at least store the data for later retrieval and, often, to perform the data processing.

The connection works both ways, of course, so connecting the sensor to the web provides an opportunity for remote configuration and control. It also triggers a need for ensuring the security of both the data sent and of the control commands coming in (see EE Times: The Day When the Industrial IoT Gets Hacked). Authenticating, provisioning, and monitoring the status of a sensor multitude are additional needs that arise from connectivity. Thus, an IIoT industrial sensor is actually a complex collection of hardware and software that spans the gap from the device at the edge to the services in the cloud. How one goes about establishing this collection varies considerably by situation. Fortunately, there is also great variation in the products and services available for designers to apply.

Bringing a sensor system into the IIoT requires a complex ecosystem of hardware and software. (Image: Disruptive Technologies)

For many developers, legacy sensor systems will be the IIoT candidates. Industrial equipment typically has a service life measured in decades, so there is a huge installed sensor base that needs conversion to internet connectivity. Developers can start by adding smart radio modules, such as those from Link Labs, that can tap into existing sensor interfaces and provide the necessary protocol conversion as well as connectivity. There is a variety of radio networks available from which to choose as well, including Wi-Fi, Bluetooth, LoRaWAN, and cellular. Developers connecting legacy systems will then need to select from among the many cloud service providers and analytics software providers offering industrial services.

For new system designs, there are several options available. One, of course, is to use a design approach like that of a legacy system, starting with the bare sensor. A controller must be added to provide the sensor interface and data security, along with a radio to handle the network connectivity. As with the legacy system, designers must then arrange for the cloud services.

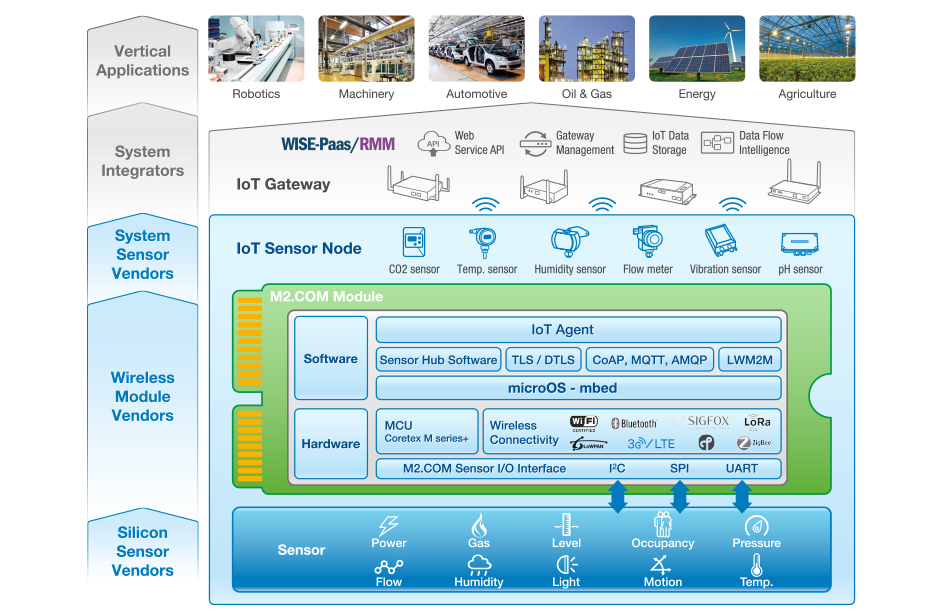

Developers need not work entirely from scratch when creating a new system, however. Several platform-based approaches have arisen that simplify combining the sensor, controller, and radio components by allowing a mix-and-match assembly of compatible components. An example is the M2.COM platform jointly developed by Arm, Advantech, Bosch Sensortec, Sensirion, and Texas Instruments. This platform uses a standardized form factor and interfaces to allow developers to choose a conforming sensor and a wireless module from one of many different vendors, then simply plug them together, install the platform’s IoT software agent, and develop their application program to create a sensor module that can then be used with a variety of cloud platforms.

Assembling an IIoT sensor system is simpler when using standardized building blocks, such as with the M2.COM platform. (Image: M2.COM)

Several such cloud platforms are available that were specifically created to address industrial sensor needs from vendors that do not make the sensor modules themselves. These include smaller companies such as Akoom and Kaa IoT Technologies, more established players such as the PTC ThingWorx platform, and industry giants such as GE’s IoT software and Siemens’ Mindsphere platforms.

Developers can also choose to forego developing their own smart sensor module and choose to start with a higher-level building block. Fully integrated smart sensors, with built-in controller and radio functionality, are available from companies such as Disruptive Technologies, Episensor, and Zenseio. An unusual approach by Axzon (formerly RFMicro) uses RFID in the sensor module, avoiding the need for wireless spectrum management but requiring active scanning with a handheld device to retrieve data and send it to the internet. Advantech, one of the M2.COM founders, also offers complete smart sensor modules through its Wzzard family, which includes both LoRA and mesh network approaches.

A complete IIoT sensor system, such as this member of the Advantech Wzzard family, integrates sensor, controller, and wireless link into a ruggedized package. (Image: Advantech)

What all of these integrated smart sensor offerings have in common, though, is that the vendors are not just providing smart connected sensors. They also offer gateways and software to securely get the data all the way to the cloud in a form compatible with cloud platform service providers. This relieves designers of all the hardware effort needed to establish an IIoT sensor system if their sensing needs are met by one of the available modules.

The system integration needed to marry even a smart sensor system with the many software services needed to ensure security and to manage and extract actionable intelligence from IIoT sensor systems is still significant. To relieve designers of this burden, numerous companies are now offering complete end-to-end packages, from the sensor through cloud device management and analytics services. Some are smaller offerings, like the IoTini I2OT family, which primarily offers environmental sensors as well as universal analog and digital sensor interfaces. QBurst focuses its sensor on applications for monitoring rather than industrial control.

But there are also some major players in the edge-through-cloud IIoT sensor system market. These companies typically offer a variety of sensors and configurations, often with custom design support as well. ABB, for instance, offers end-to-end and closed-loop systems through its ABB Ability program. Bosch-Sensortec offers several universal sensor modules and supports the M2.COM development approach. Rockwell Automation’s Allen-Bradley division also offers general-purpose sensors as well as more specialized pressure and image sensors, leveraging its IO-Link radio technology.

Whether connecting legacy sensor systems to the internet or creating new systems, designers have a multitude of choices for IIoT sensor systems. (Image: Versasense)

Closing the loop is Versasense. The company’s many offerings include complete edge-to-cloud sensor systems as well as gateway devices and cloud services. It also offers devices that allow connection to legacy sensors, translating their protocols to bring them from factory networks into the IIoT. These legacy connections can then utilize the cloud management and analytics services that form part of the Versasense family.

However it is done, gathering data and getting it into the cloud, where it can be turned into information and actionable intelligence, has tremendous potential to help optimize and cost-reduce industrial operation. Developers need to choose the approach that best suits their specific needs from among the many that are available.

— Richard Quinnell is editor for special projects at AspenCore.

This article is part of the AspenCore Special Project on industrial IoT sensors. Check out these other articles from the Industrial IoT Project.

The role of Sensors in the industrial IoT (IIoT)

Deploying IIoT sensors in the Smart Factory

Jumping into Industry 4.0 with Predictive Maintenance Solutions

For more insight into sensors, check out these other articles across the AspenCore network.

7 Controllers for Internet of Things

Intelligent, IO-Link connected sensors underpin the Industrial Internet of Things

Industrial sensors and control — The basics — Parts I , II , III , IV , V , VI , VII

Advertisement

Learn more about Electronic Products Magazine