THERESE JORDAN, SVP of Business Development,

RAJUL RANDIVE, Director of Application Engineering,

Crystal IS,

www.cisuvc.com

Water purity is a major concern for developing and developed nations ―scarcity of clean water leads to more deaths annually than from all forms of violence combined, including war. Even in the United States, there is ongoing concern over the increased impact of drought in areas such as California and the Southwest. This has dwindled fresh water reserves and aquifers at an alarming rate. Incorporating ultraviolet (UV) disinfection is a major part of the water reuse strategy in these drought-stricken states. Moreover in other parts of the world such as India and China, disinfecting water at the point-of-use (POU) is rapidly becoming the preferred method to ensure safe drinking water in residential areas.

The most common form of water disinfection involves chemicals, such as chlorine or iodine, because of the relatively low cost. However UV disinfection has been used for over 100 years and is growing in popularity as concerns over the impact of chemical processing climb. Unlike chemical methods, UV cannot be overdosed and does not produce by-products, toxins, or volatile organic compound (VOC) emissions. It does not require the storage or use of hazardous materials, and will not affect smell or taste. In addition, UV light is known to kill more waterborne microbes than chlorination or iodine.

In UV disinfection, short wavelength ultraviolet (UVC), light in the range of 250 to 280 nm disrupts the DNA of microorganisms rendering them unable to reproduce. The action spectrum for bacteria is commonly reported and shown as a response from 200 to 300 nm with a peak between 265 to 267 nm wavelengths, with some variation across species. Low-pressure mercury arc lamps have become a common way of accessing the germicidal portion of the irradiation spectrum. As a plasma, they emit a discrete wavelength at 253.7 nm. Although this is not the optimum germicidal wavelength, there is sufficient emission to disrupt DNA and they are now standard in water treatment and reuse industries.

UVC LEDs are a viable alternative to mercury lamps. Here the spectral response is continuous, as opposed to mercury’s line response and the peak of the emission may be tailored to overlap the action spectra of microbial species to optimize disinfection (see Fig. 1).

Fig. 1: Spectral comparison of low-pressure mercury lamps versus LED in relation to germicidal effectiveness curve.

Enabling more efficient reactor designs

UV reactors are a mainstay for water treatment facilities and residential appliances designed to disinfect water flowing through a system. Optimum design ensures UVC light is delivered in the most efficient and effective manner by maximizing overall UV dosage and delivering uniform light distribution so no target microbes escape exposure. To achieve this, system designers consider flow cell size and shape, water flow rate in the cell, and UV power of the system.

Flexibility for flow cell size and shape

With traditional disinfection systems the reactor design must adapt to the shape of the mercury bulb—a long, cylindrical tube (see Fig. 2a). This shape dictates the footprint of the UV unit in the water system—limiting the system designer’s options in overall size and configuration of the disinfection reactor. Conversely, UVC LEDs are a point light source in a durable, compact package, which creates an opportunity for maximum design freedom and a host of new considerations regarding the reactor footprint (see Fig. 2b, c, d). The small size of the UV source enables smaller POU disinfection systems. Moreover, new configurations allow designers to more easily address the maximum fluence rate and field uniformity to produce ever more efficient reactors.

Fig. 2a:Flow cell with center-mounted mercury lamp;

2b: Flow cell with UVC LEDs mounted in end caps;

2c: Flow cell with UVC LEDs positioned inside the tube;

2d: Irregular-shaped flow cell with UVC LEDs mounted inside. In practice LEDs would be separated from water with a leak-proof UVC transparent housing.

Maximizing the fluence

Average flow rate sets the baseline for exposure time of the waterborne pathogen to the UV source. A drinking water system built to the highest sanitation criteria, via an independent standard (NSF 55 Class A), requires a dosage of 40 mJ/cm2 . In flow cell design, understanding flow distribution beyond the average is key to maximizing dosage at a local level and can be optimized by increasing residence time in the flow cell for the greatest exposure to UV light. Reactor designers often employ computational fluid dynamics (CFD) and optical modeling (ray tracing) to develop custom systems based on the specific requirements of an application.

An example of residence time manipulation is illustrated in Fig. 3 using two reactors based on the configuration seen in Fig. 2b. Here the reduction in microbes under identical UV power is considered. The tests were performed at three flow rates with a UVT of 90% and a single power input (100%). Each test used samples taken of the influent and effluent. The influent was seeded with MS2 and T1 coliphage. The bench test influent and effluent samples were analyzed for each phage surrogate. Both systems process the same amount of water, have the same overall dimensions, and the same UVC LED arrangements. However, the designs were altered to maximize the residence time with all other variables fixed by shifting the position of the water inlet and outlet. Concept A has a mean residence time of 3.09 s, while Concept B has a mean residence time of 3.72 s.

Fig. 3: Comparison for Concept A and Concept B for flow cell for MS2 and T1 reductions.

The data shows that Concept B has greater reduction for both MS2 and T1. This means that a slight change to the design to increase the residence time, even by a small amount, has a significant impact on the disinfection results.

Optimizing the field of uniformity

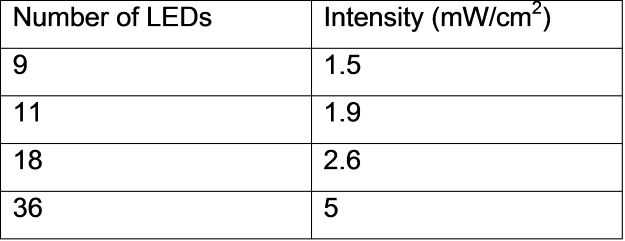

In systems where there is less flexibility around flow rate, system designers must optimize the intensity of the UV light. Increasing the light output of the system or improving the UV reflectance of the materials can accomplish this. Table 1 shows the results of an experiment in increasing the system’s UVC light output using a flow cell that has a diameter of 7.62 cm and is 90-cm long. Each UVC LED in the system has an output power of 10 mW and the intensity is measured at the center of the flow cell. Logically, as the number of LEDs is increased, the intensity at the center of the flow cell also increases.

Table 1: Experimental results from increasing the system’s UVC light output using a flow cell that has a diameter of 7.62 cm and is 90-cm long.

In designs where the light source footprint is a premium or there is a need to increase efficiency, system designers can optimize the field of uniformity by using materials with highly reflective properties for UVC light. This maximizes internal reflection to take full advantage of the UV light emitted from the light source. The most common material used in UV disinfection systems is stainless steel, however it only has 28 to 33% reflectance of UV light. Materials that contain e-PTFE (expanded PolyTetraFluorEthylen) provide over 90% reflectance in the UVC range—making systems constructed of these materials almost three times more effective than traditional reactors.

As the performance of UVC LEDs increases, designers are beginning to leverage the benefits of design flexibility to integrate UV disinfection into more POU water disinfection designs. The benefits of LEDs in these low flow applications allows for greater access to safer drinking water for communities and individuals. As global threats to safe water continue to rise, increasing the accessibility of this technology and its benefits will become the focus for innovation in the water industry.

Advertisement