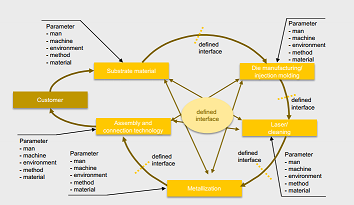

In the development of spatial electronic assemblies, the design freedom offered by the injection molding process and selective metallization opens up enormous potential for function integration. Above all, it is possible to implement mechanical and electrical functions. For example, the production of contact surfaces for switches, inductors, resistors, antenna, shielding surfaces, mounting elements, cooling fins and the exact alignment of sensor elements can be integrated. Moreover, the integration of fluid, thermal and optic functionalities is also an available option. In addition to expanded functions, there is an accompanying focus on component miniaturization, which usually achieves weight reduction.

With a design that is suitable for production (DFM – Design for Manufacturing), it is possible to not only develop an innovative product design, but also benefit from enormous streamlining potential during the component manufacturing. Numerous applications running in series production illustrate how the assembly or manufacturing process is simplified thanks to a reduced number of parts. A reduction in the interfaces also delivers increased component reliability.

When selecting the technology, the strengths of MID technology should always be fully exploited. A redesign that merely relies on MID technology for existing products is usually not expedient. Instead, it is better to aim at expanding the function and/or simplifying the product, often in connection with achieving lower costs. HARTING Mitronics has qualified the laser direct structuring and two-component injection molding manufacturing technologies and has successfully established them in series production. The materials and technology must be adapted to the application's requirements, the utilization conditions and the connection technology. As with other technologies, developers here must balance the concerns of quality, time and costs. It is important to decide if the desired application can be implemented with MID technology in the required time at reasonable costs and in keeping with the required reliability, and if the solution provides an advantage over competitor solutions.

Advertisement

Learn more about HARTING, Inc. of North America