Melexis has introduced two development kits (DVKs) to help designers with current sensor evaluation. The modular dev kits enable engineers to evaluate the functional capabilities of the company’s current sensors, delivering faster time to market.

One DVK allows engineers to experiment with arrangements featuring IMC-Hall technology (with or without shielding). Melexis’ Integrated Magnetic Concentrator (IMC) enables contact-free measurement of busbar current in combination with a U-shape magnetic shield. The sensor is positioned over the busbar within the shield when mounted on a PCB, which delivers easier assembly than conventional Hall sensors, according to Melexis.

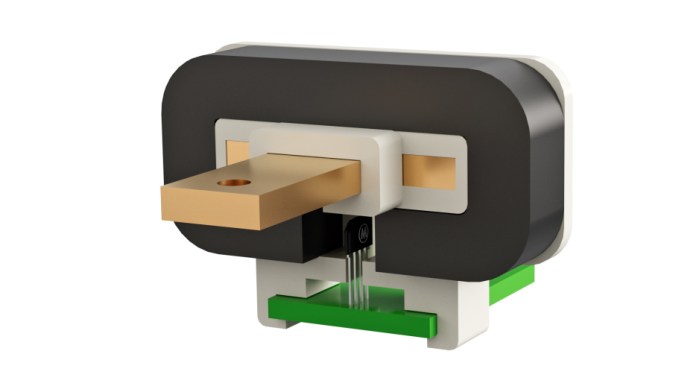

The other DVK enables evaluation of conventional core-based Hall technology. With the DVKs, engineers can validate their hardware with different sensor capabilities and cover different current sensing ranges.

Development kit for the Melexis IMC-Hall current sensors. Click for a larger image. (Source: Melexis)

The DVKs include several Melexis current sensors, so engineers can test different magnetic configurations and ICs to speed up the selection process. The DVK for IMC-Hall technology includes the MLX91208 and MLX91216 ICs, plus the recently launched MXL91218. The DVK for conventional Hall comes with the MLX91209, MLX91211, MLX91217, and MLX91219 current sensors. These devices cover the company’s second generation of external primary current sensors.

Development kit for the Melexis conventional Hall current sensors. Click for a larger image. (Source: Melexis)

The DVKs also include 3D-printed holders to keep the shields and cores (if applicable) firmly in place and bus bars to simplify the set-up process, said Melexis. Materials used in the DVKs can withstand higher temperatures (170℃), according to the company.

Advertisement

Learn more about Melexis Microelectronic Systems