Industrial monitoring and control is a significant application for the emerging Internet of Things (IoT), one with a clear potential for a significant return on investment. But retrofitting legacy industrial systems with networked monitoring and control devices can be a significant design challenge. The Pocket IO PLC development platform simplifies and speeds up Industrial IoT design by providing a powerful, compact, low-power networked monitoring and control unit that developers can use to prototype and experiment.

Sensing and control of industrial systems has evolved. Simple sensors that merely sent data now have bidirectional communications to enable remote control of configuration and settings. Programmable logic controllers have moved from centralized to distributed control and have become more capable. Together, the two trends have enabled the creation of intelligent control systems that make local decisions about industrial activity and are reconfigurable to alter or implement processes on the fly.

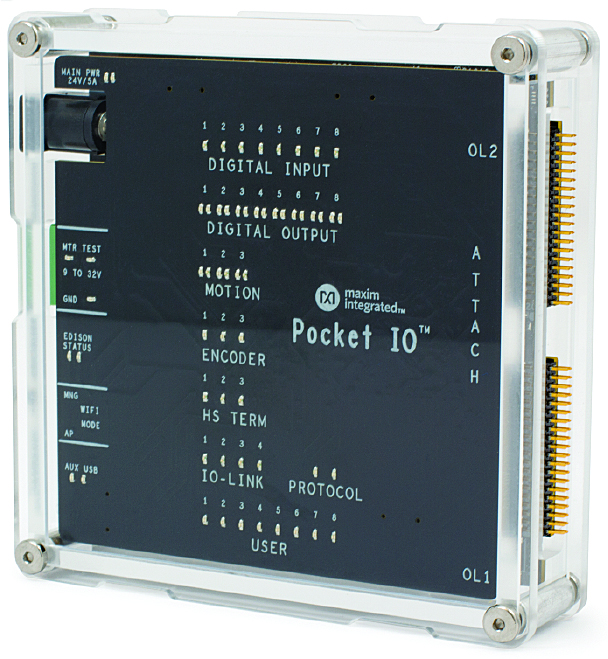

The Pocket IO development platform provides the processing, communications, and sensor interface capabilities needed to implement such intelligent control systems. It is compact (3.5 x 3.5 in.), programmable (Arduino Sketch or Intel Edison IDE), and environmentally rugged, using parts rated for –40°C to 125°C. For power, it can operate from batteries through 42 Vdc. It offers a suite of 30 IO ports, including analog, isolated digital, motor control, and both serial and field bus interfaces. Communications to the device take place over USB or Wi-Fi, and developers can utilize a smartphone as their graphical user interface. This abundance of resources provides developers with the ability to get started with adding connected sensing and control to legacy systems and enter the Industrial IoT era.

The Pocket IO development platform provides the processing, communications, and sensor interface capabilities needed to implement such intelligent control systems. It is compact (3.5 x 3.5 in.), programmable (Arduino Sketch or Intel Edison IDE), and environmentally rugged, using parts rated for –40°C to 125°C. For power, it can operate from batteries through 42 Vdc. It offers a suite of 30 IO ports, including analog, isolated digital, motor control, and both serial and field bus interfaces. Communications to the device take place over USB or Wi-Fi, and developers can utilize a smartphone as their graphical user interface. This abundance of resources provides developers with the ability to get started with adding connected sensing and control to legacy systems and enter the Industrial IoT era.

Advertisement

Learn more about Maxim Integrated