By Jean-Jacques DeLisle, contributing writer

Diodes can be found in many devices across a multitude of fields. A diode, simply put, is a semiconductor that allows an electric current to flow in only one direction, making it an essential part of many applications. Recently, several major manufacturing companies have released new diodes aimed at automotive and communication industries.

Companies such as Bourns, Littelfuse , and Nexperia have already produced new diodes that deliver many advantages over their predecessors.

Bourns Inc., for example, rolled out a new TVS diode series that features low capacitance of 3 picofarads (pF), a feature that makes them well-suited protection devices for the high-speed interfaces and other applications that require low capacitance. Model CDSOD323-TxxC-DSLQ TVS diodes also offer Bourns' lowest TVS diode leakage current of just 1 nanoampere (nA). These diodes are essential for IoT sensors and other applications in which long-lasting battery life is important. TVS diodes aid these sensors and other automotive tech by being more efficient and wasting less energy, which allows the automotive equipment to run longer and consume less power, a boon for anyone designing and manufacturing them.

David Scoffield, TVS diode product manager at Bourns, provided some insight into how these new diodes work. “A TVS diode protects interface lines by connecting to protective grounds. During normal situations, the TVS diode should be transparent and look like an open circuit to ground. Any parasitic capacitance, or leakage, to ground would cause distortion to the signal on the line. The line signal of high-speed interfaces is especially sensitive to such parasitic capacitances and leakage. Hence to preserve signal integrity it is important to ensure protective devices on the line have minimal capacitance and leakages.”

This means the new diodes are more efficient and waste far less energy, a quality that makes them highly desirable for automotive industries and other similar applications.

Scoffield explained that the electronification of the automotive industry is leading to significant growth in the amount of data that is being collected, transmitted and processed. “High-speed interfaces are being used in the transmission of voluminous data,” he said. “Some of these interfaces are subject to ESD whether due to being exposed to the user, e.g. USB3.0 ports and touchscreens, or due to the functionality and environment.”

Nexperia, a former Standard Products division of NXP, also has released several new diodes with some extremely advanced features. The new parts are interchangeable drop-in replacements for legacy devices. To make these new diodes compatible, they will be available in standard SOT23, SOD323 and SOT323 packages.

Nexperia has developed new parts that deliver higher performance in a variety of ways. The new PESD2IVN24-T part, for example, delivers 30 kV ESD protection over the previous 23-kV models. These new models also feature an improved surge current of 3.5 A and an advanced clamping voltage of 42 V at 3.5 A (compared to 70 V at 3 A for the legacy part). Other features of the diodes are similar to previous models, but with small advancements. The idea is to make diodes that are far better than previous models, but not so different that they would not be interchangeable.

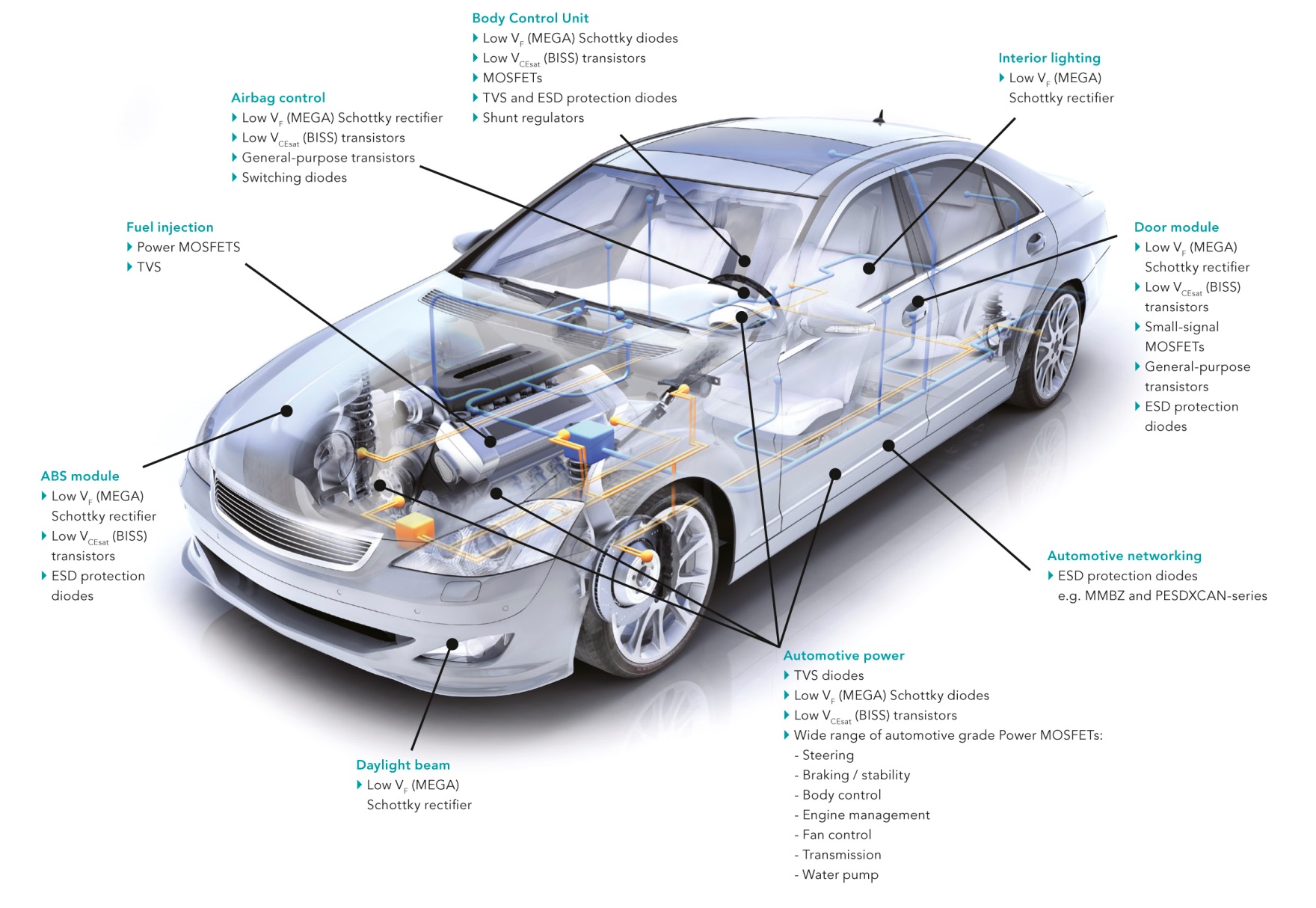

Image source: NXP.

“In modern vehicles, there is an increasing amount of data exchange and the electronic content is growing in functionality and complexity, therefore effective ESD protection solutions are imperative. Nexperia has brought online a massive capacity increase for ESD diodes in order to guarantee a secure chain, and provide customers with peace of mind that they are protecting the electronics in their vehicles with high-performance, rugged and efficient devices,” said André Dressler, Nexperia’s marketing manager automotive.

Littelfuse is another company that is following the trend of more efficient, advanced diodes and has released several new models. Among these new models are the AQHV and AQHV-C series that are designed to give extremely fast acting, high performance, over-voltage protection. These are suited for power interfaces, passenger charging interfaces, as well as LED lighting modules, and low speed I/Os. Typical applications include ESD protection for automotive electronics, LED lighting modules, mobile/handheld devices, CAN BUS (drive-by-wire), LIN BUS, RS-232 and RS-485 interfaces, general-purpose low-speed I/Os, and portable instrumentations.

“As AEC-Q101 qualified devices, the AQHV and AQHV-C Series can ensure maximum reliability in the harshest environments,” said Tim Micun, director of TVS diode arrays (SPA diodes) at Littelfuse in a press release. “That makes them a great option for designers who need to replace passive ESD protection or to ‘sprinkle’ protection devices around a printed circuit board.”

The rise of such diodes is part of a trend seen in many areas around the tech world. Smaller, more powerful components are allowing designers to revamp older designs. This allows developers to increase efficiency and power without having to ‘go back to the drawing board’ and start over completely. By designing these new diodes to effectively be ‘dropped in’ as needed, developers can replace an older model or increase the efficiency of a device without having to redesign the entire system.

Littelfuse’s TVS diode arrays are capable of handling >1000 ESD strikes or surge transients without performance degradation. This improved longevity is an advancement that comes in contrast to alternative technologies that have an inherent wear-out factor and low dynamic resistance. These models provide up to 60 percent lower clamping voltages. These advancements coupled with the ESD protection up to ± 30 kV, and surge protection up to 8 A, help equipment manufacturers comply with exceedingly harsh industry standards, and may significantly extend the life of technical equipment and improve system uptime.

Advertisement

Learn more about Electronic Products Magazine