By Alix Paultre, contributing editor

Industrialization has been a force in human society since complex machines became a reality. Watermills became steam-driven factories, which are now becoming smart facilities. The current drive to Industry 4.0 may become Industry 5.0 while our backs are turned as artificial intelligence (AI) is injected into the mix. Properly integrated software and hardware can address almost any application that they are applied to today.

However, one critical aspect of any societal change is the infrastructure required. The iPod wasn’t just a marvel of consumer technology; it was also the tip of a massive iTunes content infrastructure iceberg. Without developed core technologies and established functional infrastructures, no real progress can be made.

That’s why the electronics industry congregates at events like the Applied Power Electronics Conference (APEC), coming to Anaheim, California, in 2019, and the recent Power Control and Intelligent Motion (PCIM) conference in Nuremberg, Germany, and why they are so important. These events bring engineers and vendors together to show and learn about the latest solutions in power management and motion control.

The great thing about the electronics industry is that the magnitude of the news isn’t a factor of the size and budget of the companies creating it because engineering is about the quality of the solution, not the loudness of the announcement. New devices, services, and partnerships are what make the industry move forward.

New topologies and technologies

One of the bigger pieces of news isn’t actually a product yet but promises to be. A startup called Pre-Switch unveiled a new power topology to the marketplace at PCIM. The key lies in its core technology, called Pre-Flex, that uses an embedded AI-driven controller chip to effectively eliminate transistor switching losses in hard-switched power architectures.

If the solution turns out to perform as promised, it would greatly help power applications in the server, solar, wind, electric vehicle, traction, and motor drive markets. According to the company, Pre-Flex technology learns and adapts “in-system” on a cycle-by-cycle basis to reliably force resonant soft-switch across changing loads and input voltages.

Beyond the hot news of the Pre-Switch topology, there was a lot of other cool technology at the show. The Vicor Power-on-Package solution was an example of some of the interesting solutions demonstrated as it established a new benchmark in power density for 48 V directly to CPU/GPU power rails.

Vicor Corp. unveiled its Power-on-Package ChiP-set including modular current multipliers (MCMs) for high-performance GPU, CPU, and ASIC processors. The devices multiply current and divide voltage from a 48-V source to enable higher levels of XPU performance. Power-on-Package modules build upon Factorized Power Architecture, which supports efficient power distribution and direct conversion from 48-V to sub-1-V XPUs.

Owing to their high-density, low-profile package (46 x 8 x 2.7 mm) and low-noise attributes, MCMs are suitable for co-packaging within the XPU substrate or adjacent to it. Close proximity to the XPU eliminates substantial power loss and bandwidth limitations incurred in “last-inch” current delivery from the boundaries of 12-V multi-phase regulators.

Alpha and Omega Semiconductor introduced a family of EZBuck regulators featuring I2 C control. The 4-A AOZ2231CQI-01 and the 8-A AOZ2233CQI-02 provide a compact, efficient power converter solution for next-generation chipsets and FPGAs used in advanced embedded systems. With microprocessors and SoCs often using dynamic voltage scaling, the 4-A AOZ2231CQI-01 and the 8-A AOZ2233CQI-02 allow the system designer to control the output voltage from 0.6 V to 1.79 V using an I2 C interface with 9.375-mV steps.

Both the 4-A and the 8-A devices are available in footprint-compatible QFN 4 x 4-mm packages, allowing designers an easy upgrade path as power requirements increase. The devices

operate over an input voltage range from 6.5 V to 28 V and have a built-in 5.3-V regulator, making single-supply operation possible. The proprietary COT architecture provides ultra-fast load transient response performance and allows stable and low-voltage ripple operation with small ceramic capacitors.

Wide-bandgap semiconductors

Wolfspeed , a Cree Company, showed several of its latest solutions, including the company’s third-generation 1,200-V silicon-carbide (SiC) MOSFET family. This switching device, which enables high-voltage power conversion, is useful in both industrial and electric vehicle applications. Wolfspeed’s new C3M 1,200-V SiC MOSFET technology is capable of handling high current with the industry’s lowest drain-source on-resistance (RDS(on)) performance at 1,200 V and the lowest switching losses, giving it the highest figure of merit on the market currently.

Infineon Technologies AG announced that it will have volume production for its CoolGaN products by the end of 2018, with engineering samples available now. Presented as one of the most reliable and globally qualified GaN solutions in the market, the devices go through a quality management process that not only tests the device but also its behavior in the application.

ON Semiconductor is expanding its SiC Schottky diode portfolio, adding AEC-Q101 automotive-grade SiC diodes for demanding automotive applications. Available in surface-mount and through-hole packages, including TO-247, D2PAK, and DPAK, the diodes have no reverse-recovery current, and switching performance is independent of temperature. They also have a novel termination structure that improves reliability and stability, with an operating temperature range from –55°C to 175°C.

ON Semiconductor’s SiC diodes for automotive apps. Image Source: ON Semiconductor.

Of course, driving your transistors is as important as the devices themselves, and AgileSwitch is addressing the latest wide-bandgap designs with the ASC1 (AgileSwitch Software Configurable Core 1) SiC MOSFET gate driver core. Features include software-configurable Vgs, a robust high-noise-immunity design, advanced monitoring and fault reporting, and a compact form factor. The drivers are available with a family of tested reference adapter boards to help provide compatibility with most SiC MOSFET modules.

The ASC1 driver core features a configurable gate voltage and uses the company’s software-configurable augmented turn-off (ATOff) technology. The ASC1 gate driver core is designed for harsh, high-noise environments and is available with conformal coating. It is equipped with powerful diagnostic and troubleshooting tools and it continuously monitors critical parameters such as temperature and DC link voltage.

Solutions for demanding applications

KEMET is targeting industrial and automotive markets with a series of power film capacitors that meet the requirements of AEC-Q200. The new RoHS-compliant capacitors have a polypropylene metallized film construction and are available as two or four radial-leaded board-mount devices.

Available values for the C4AQ series range from 1.0 µF to 130 µF, with additional sampling for 170 µF and 210 µF. Voltage values span from 500 Vdc to 1,500 Vdc. Devices from the C4AF series are designed for use in more demanding and harsh applications and are offered in capacitance values up to 62 µF with voltage ratings up to 400 VAC.

The power film capacitors are also well-suited for high-frequency applications, with rectangular, resin-filled enclosures and an array of application benefits including self-healing characteristics and low losses. Additional features include high-ripple-current values, high-capacitance density, and high-contact reliability, with an operating temperature range from –55°C to 105°C.

The DVC 1000-P for insulated nominal-voltage measurements in traction and industrial applications from LEM USA Inc. uses isolating amplifier technology. With a safety insulation voltage of 4.2 kV, the DVC 1000-P transducer measures only 37 x 43 x 23. 5 mm and mounts with a total volume of 37.4 cm3 .

The DVC 1000-P is compliant with the International Railway Industry Standards and can measure DC link, an output voltage of inverter, input voltage of four-quadrant converters, or a battery voltage. The DVC 1000-P transducer measures voltages by a direct connection on its primary side. An isolated signal creates a voltage at the transducer output connections that is an exact representation of the primary voltage. No additional components are necessary; it just has to be connected to the voltage to be measured.

Overall accuracy is ±1% at 25°C with a high stability in temperature leading to an overall accuracy of ±1.5% from –40°C to 85°C. Its measurement frequency bandwidth (–3-dB point) is 47 kHz, and the DVC 1000-P consumes only 35 mA at no primary voltage when power supplied is under +5 VDC.

The Power Integrations SCALE-iDriver gate-driver IC family has two parts that are now certified to AEC-Q100 Grade Level 1 for automotive use. The two parts, the SID1132KQ and SID1182KQ, can drive 650-V, 750-V, and 1,200-V automotive IGBT and SiC-MOSFET modules and are rated for peak currents of ±2.5 A and ±8 A respectively.

Power Integrations’ SCALE-iDriver family for automotive use. Image Source: Power Integrations.

The FluxLink magneto-inductive bi-directional communication technology provides reinforced galvanic isolation between the primary and secondary sides to eliminate the need for optoelectronics. Their compact and robust eSOP package offers a CTI level of 600, 9.5-mm creepage and clearance distance, and easily meets automotive 5,500-m requirements.

The latest generation of reinforced isolated power converters from Analog Devices Inc. (ADI) allow systems to meet EN 55022/CISPR 22 Class B electromagnetic interference (EMI) requirements. The ADuM5020/6020 and ADuM5028/6028 series eliminate the need for costly EMI mitigation techniques at the application level and simplify the EMI certification process.

Emerging safety-critical applications like industrial programmable logic controllers require compact and dense isolated designs, and use of these devices can achieve emissions targets on a two-layer PCB, which reduces the solution size by as much as 70% and decreases the material cost by 30% compared to a four-layer board.

Building upon ADI’s iCoupler and isoPower chip-scale transformer technologies, the new 500-mW DC/DC power converters support high temperature operation up to 125°C in a small 8-lead form factor.

Test and measurement is always a battle to stay ahead of the systems that you are testing. Tektronix’s latest probing solutions address the latest advances in wide-bandgap semiconductors and power topologies. Based on optical technology, its IsoVu family of probes offers complete galvanic isolation between the test point and the oscilloscope. IsoVu has a 1-million-to-1 common-mode rejection ratio up to 100 MHz and 10,000-to-1 common-mode rejection up to 1 GHz, with no derating as frequency increases.

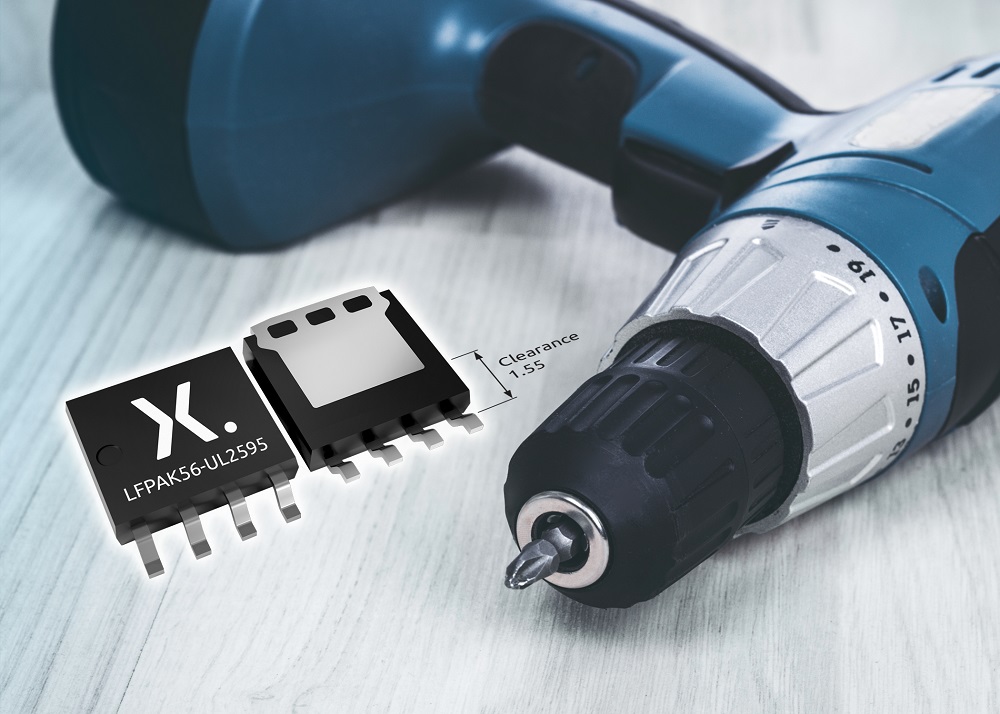

Nexperia announced that two of its LFPAK56-packaged portfolio of MOSFETs have improved creepage and clearance to meet UL2595 requirements for battery-powered equipment rated between 15 V and 32 V. Unlike some competing Power-SO8 types, which are constructed using wire bonding, Nexperia’s LFPAK56 package uses a copper clip that is soldered in a single operation to the surface of the die, reducing spreading resistance and improving electrical and thermal characteristics while increasing reliability.

Nexperia’s LFPAK56-packaged portfolio of MOSFETs for battery-powered equipment. Image Source: Nexperia.

The new PSMN0R9-30ULD and PSMN1R0-40ULD N-channel MOSFETs in the enhanced SOT1023A package feature a creepage distance of 1.5 mm and a clearance distance of 1.55 mm. The PSMN0R9-30ULD device is rated at 30 V, offering 0.87 mΩ and 300 A, while the PSMN1R0-40ULD is rated at 40 V with 1.1 mΩ and 280 A.

Advertisement

Learn more about Electronic Products MagazineNexperiaTektronix