BY DEBBIE SNIDERMAN, CEO

VI Ventures LLC

www.vivllc.com

Ultra-low-power displays, such as e-paper displays with E Ink, are used in many applications in which a power-hungry backlit LCD isn’t suitable. With a 180° viewing angle and excellent readability indoors and outdoors, electrophoretic displays are like viewing printed ink on paper. Displays using E Ink are the only ones that have high reflectivity and contrast, a wide viewing angle, and are ultra-low-power.

Why e-paper displays are important now

HD Lee, CTO and President of Pervasive Displays (PDi), the Taiwan-based display design house specializing in ultra-low-power e-paper displays primarily for retail electronic shelf labels (ESLs), says that they are much more than beautiful price tags.

These shelf labels display up-to-date information, such as stock levels and product information, in real time, integrate with customer referral programs to show star ratings and product rankings, and can last up to five years on one battery charge. They’re also important in stores that have thousands of products that would be impossible to connect with wires.

Chairs in Westminster Abbey supplied by Casala use simple, energy-free e-paper displays from Pervasive Displays that don’t require batteries.

Michael McCreary, Chief Technology Officer at E Ink Corp., says that new products are often introduced using these types of displays, from shelf signage to point-of-purchase displays to package-tracking labels. The package-tracking labels offer the ability to display multiple messages at different stages of a shipment’s journey and even change a parcel’s destination while en route, a key feature for last minute re-routing, just-in-time deliveries, or inventory adjustments. And the age of IoT is coming, when most devices are battery-driven and users demand long battery lives.

How they work

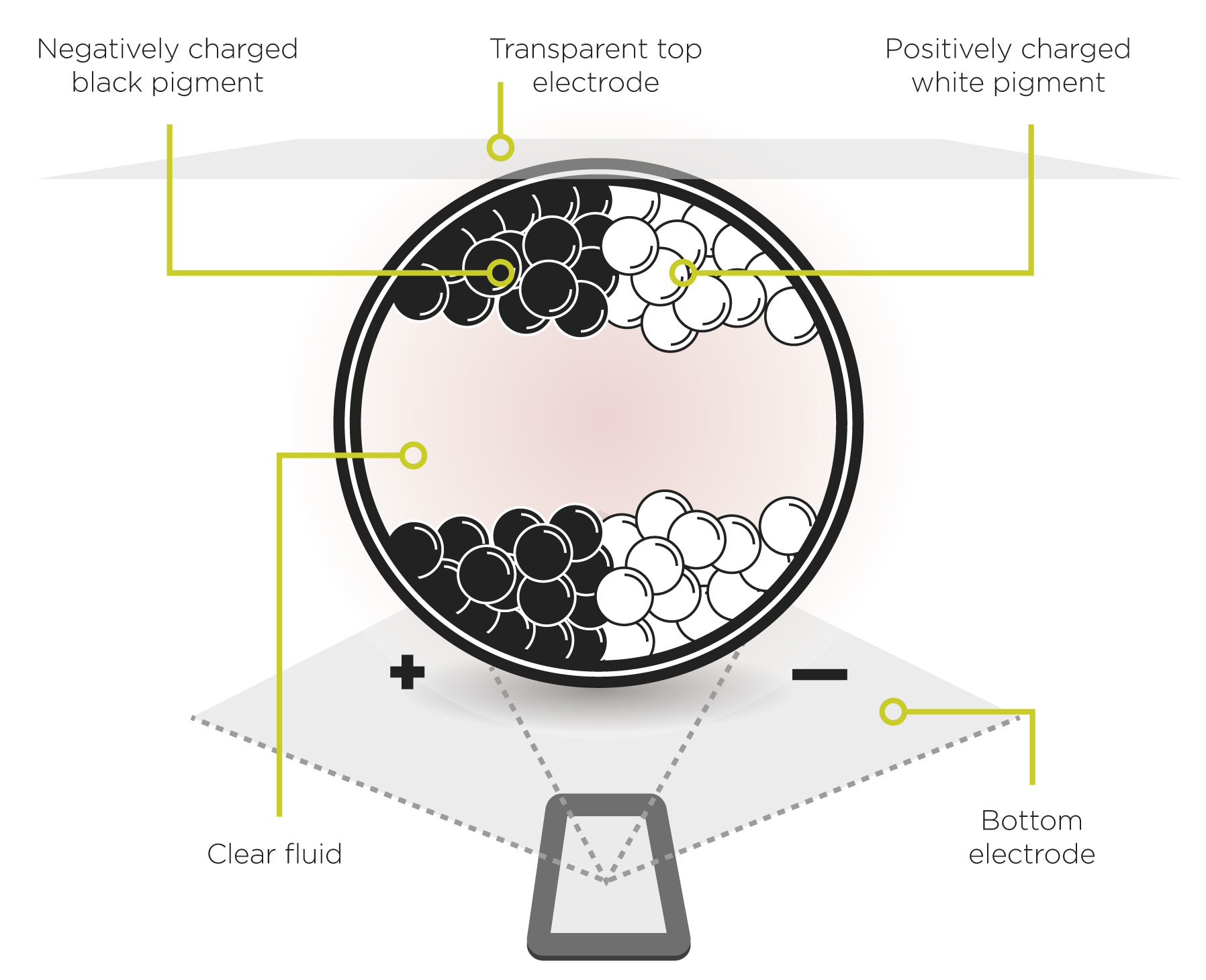

E Ink’s displays are very different from conventional OLED and LCD displays, which need a backlight to display an image. All have backplanes to drive them, but that’s where the similarities end. E Ink displays use black-and-white or colored particles that are charged and suspended in a clear liquid that is encapsulated in either sealed microcups or microcapsules and coated onto a clear film. This film is sandwiched between a back electrode and an unpatterned transparent front electrode.

The 42-in. E Ink display provides digital signage solutions across industries like public information, retail, and transportation.

The simplest form contains black particles, which are charged negatively, and white particles, which are charged positively. When an electric field is put across the sandwich, positive on the front and negative on the back, white particles migrate toward the back and black particles migrate toward the front. The white particles are reflective, so they hide what’s behind them, and when all white particles are at the front, the display looks like a black sheet of paper.

PDi’s small 2-, 2.5-, or 3-in. bi-stable e-paper displays are mostly used for labels and are programmed by remote control. E Ink of Boston supplies the microcapsules of ink used in their display modules, which contain one or two TFTs, an ink layer, a protective sheet, driver electronics, and a connector.

E Ink displays are considered bi-stable in that power is needed only to change the image, not to maintain it. Images will remain “on all the time” for up to 10 years without power for a shelf label, and, in most cases, Lee says that e-paper customers use batteries or a solar cell to drive the display. “A watch only needs very little power to move the minute hand every minute. Most electronic readers only need to be charged every few months,” McCreary says.

With E Ink’s Spectra technology, electronic shelf labels allow retailers to have the most up-to-date prices in less than a minute.

Outdoors displays using E Ink technology look like paper, but in dark lighting conditions, visibility is also different. “OLED and LCD displays use backlighting that has to make it through the TFT backplane before it is seen. Only a small percentage is transparent, so a lot of light is thrown away. E Ink displays utilize front-lighting in dark areas, where virtually all of the light reflects back into the eyes, so they are more than a factor of 10 times more efficient. Even using front-lighting, E Ink e-readers only need to be charged once a month,” McCreary says.

E Ink displays also have Lambertian reflections, which scatter light in all directions similar to printed ink on paper, so they have much wider viewing angles than LCDs. This is important for viewing shelf labels in a store that need to be viewed while walking down the aisle before standing in front of it and from customers of all heights. Resolutions are about 200 to 300 pixels per inch, and these screens are widely used today.

Palladio Group’s PhutureMed smart packaging uses an E Ink display to allow for stricter medication adherence and safer travel for medicine.

The flexible front plane used for viewing the E Ink display is also different. It is made from plastic substrates with transparent conductors to create the field and view the ink particles through. “We coat ink on the encapsulated material a mile at a time in our manufacturing facility, roll it up, and ship it to backplane manufacturers that can be located anywhere in the world. They cut it out, like a sticker, and laminate it to their transistor backplanes to complete the displays. Because the front plane is unpatterned, it can be cut and there is no critical alignment step to display assembly,” McCreary says.

What’s new

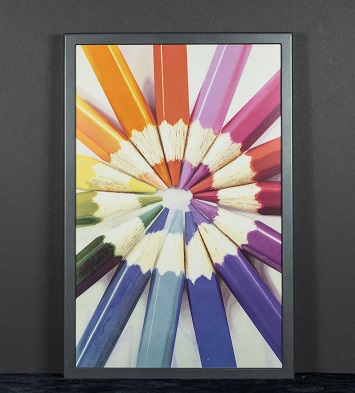

Two color displays, substituting black particles for a color, still use plus/minus charging. This new film, E Ink Prism, is used in architectural applications like color-changing walls and on furniture. E Ink Spectra, created for shelf-label applications, is a three-particle system currently available in black-and-white plus red or yellow, with more colors to come in the future.

According to Lee, three-color displays are the biggest innovation that has arisen in e-paper displays. “It took about five years to perfect three-color displays with red,” Lee says. “And we are demo’ing black/white/yellow displays now.”

E Ink’s Advanced Color ePaper (ACeP) offers a high-quality, full-color reflective display.

With three particles inside — black, white, and red or yellow — things are different. “By controlling the charges, sizes, and waveforms of not only plus/minus voltage but time and length of pulses, as well as the liquid inside the capsule, we can control all three pigments independently to have all red, white, or black in front and look as good as black and white. This requires slightly longer waveforms, so it takes a few seconds to update rather than the fraction of a second needed for black and white, but that is OK for shelf labels,” McCreary explains.

E-paper displays are also shipping with new driver support for integrated development platforms like the Energia LaunchPad family that supports Texas Instruments processors, WireIE, and Arduino. PDi also has new, very small boards to link displays together.

RIMOWA suitcases feature E Ink displays for luggage tags to reduce the risk of losing luggage while traveling and to speed check-in.

E Ink is expanding the temperature range of the displays for freezers and outdoors. Shelf labels inside a freezer are more convenient than constantly opening and closing the door, and the newest materials are freezer-cold-compatible. E Ink displays are moving toward higher temperatures as well to support outdoor signage and architectural applications where temperatures may exceed 50°C.

Flexible backplanes are another new feature that opens up markets and products for bendables, where weight and being unbreakable are important factors. “Wearables can be thinner, lighter, on all the time, and laser-cut into any pattern desired, like making a watchband from the same material as the watch. Notepad-sized displays could be writeable and extremely lightweight and won’t break. From a design standpoint, laptops don’t have to have rigid closed lids. Large architectural signs that use thousands of macro-pixels could be safer because they are made from lightweight plastic. Smart luggage tags are one of the worst environments for needing unbreakables,” McCreary says.

Electronic ink is made up of millions of tiny microcapsules that contain negatively charged black particles and positively charged white particles suspended in a clear fluid.

Design considerations

McCreary says that when considering displays using E Ink technology, designers should think about these key technical parameters: whether color or black-and-white is needed. If color is needed, will it be used as a highlight or forecolor? Does the display need to be flexible? How important is weight? Size? E Ink displays can be cut to any shape. Refresh rate?

Response time is not as fast as that for an LCD and is temperature-dependent. Black-and-white displays used in e-reader applications can be updated at speeds that exceed 250 ms. But in three-particle shelf labels, Lee says, it takes one to three seconds for the ink to update at room temperature, and up to 90 seconds at –25°C. Response time needs to be considered as part of the entire user experience, especially if integrating into a touch panel in a freezer or cold environment. Lee also adds that most design engineers are familiar with LCD interfaces, but they are different for e-paper and need to be understood.

SimpleLink Wi-Fi CC3200 with Pervasive Displays e-paper screen.

“When looking for full-color video in a dark room, use LCD or OLED displays. When designing a sign with a paper look that needs to be updated but doesn’t burn power while it is on, like a list of doctors in a hospital that may change office locations, that’s a perfect application for E Ink,” McCreary says.

“Energy use is also a higher-level consideration as it becomes more important. Buildings, accents, and informational signs need to comply with regulations controlling energy and greenhouse gas output. They are turning to E Ink displays that don’t significantly increase the energy footprint of a project,” McCreary says.

“Don’t just think about the narrow sense of the specs needed to satisfy an application. Think about the broader sense of the project managers and their higher-level goals. In the case of a building, their commitment could be to energy use. In the case of a wearable, it could be the overall user interaction and satisfaction. No buttons need to be pushed or tapped to get a beautiful display of on-all-the-time information. Specs should only be part of the consideration.”

Learn more about E Ink

Learn more about Pervasive Displays

Advertisement