By Carolyn Mathas, contributing writer

Today’s cabinets and enclosures are tasked with physically protecting equipment, ensuring data security, and preventing theft and cyber-attacks. As a result, enclosure designs are rapidly advancing with new features. No longer is a rack just a rack. Enclosures now can integrate biometrics, fingerprint readers, and cameras with motion sensors monitored remotely.

Enclosures also give evidence to the growing importance of cooling, power, and efficiency. New designs include ventilated panels, fans, and air conditioning to manage heat dissipation. Also, ruggedization, remote monitoring of field enclosures, sealing, connectivity, security, and the ability to customize are now commonplace.

Enclosure manufacturers are expanding weatherproofing capabilities, too. Polycase, for example, extended its NEMA 4X -and 6P-rated ML Series weatherproof enclosures with a new size (4.50 x 2.63 x 2.05 inches) option. The ML-24F targets small- to medium-sized electronics applications and is UL-listed to UL508A Type 1, 2, 4, 4X, 6, 6P, 12, and 13. It features a silicone gasket that protects internal components from water, dust, and dirt. It also offers a clear-cover option, molded-on surface-mount flanges, plastic PCB mounting bosses, and corrosion-resistant stainless-steel screws. The ML Series enclosures can be customized with precision cutouts and digital printing.

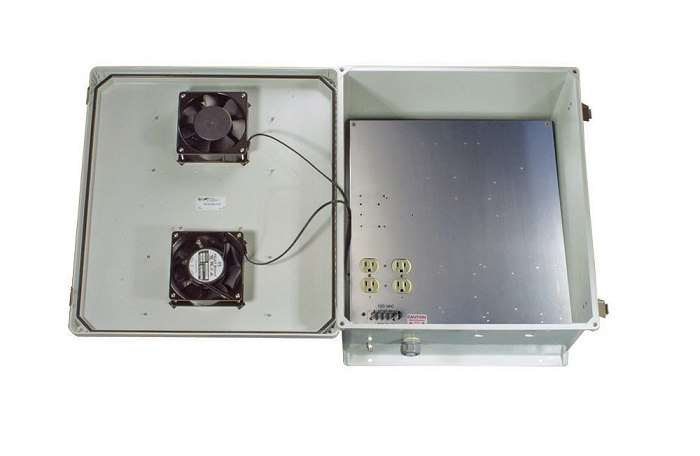

Transtector also expanded its line of NEMA-rated weatherproof enclosures with the release of its TEF18 and TEP14 lines. The TEF18 enclosures are available in 42 different standard 18- x 16- x 8-inch configurations, while the TEP14 line includes 14- x 10- x 6-inch or 4-inch sizes in 17 configurations. The company claims it has more than 100 enclosure configurations available for same-day shipping.

Transtector expands its family of NEMA-rated enclosures with the addition of the TEF18 and TEP14.

The TEF18 and the TEF14 lines are constructed of UV-stabilized polyester reinforced fiberglass. TEP14 enclosures are also available in acrylonitrile butadiene styrene (ABS). They feature fully gasketed lids and padlock capabilities for greater security. Several options are available, including non-powered enclosures, Power-over-Ethernet (PoE), 120 Vac for the TEP14, and 120 Vac, 240 Vac, or 12 Vdc for the TEF18. Additional options include vents, cooling fans, heaters, insulation, DIN rails, pre-drilled mounting plates, and UL-listed designs. Custom modifications are also available.

Demand is growing for enclosures that meet extreme temperature requirements. One example is Intertec Instrumentation’s recently launched field enclosures for remote I/O and other control and instrumentation electronics. These enclosures are designed to help eliminate the need for plant buildings such as satellite instrument houses or remote instrument enclosures, which may need to be air-conditioned and blast- and fire-resistant.

These enclosures also simplify versatile distributed control architectures that contain field equipment such as software-configured I/O, IIoT networking, and PLCs. The enclosures are factory sealed and assembled, eliminating exposure to potentially dangerous conditions at the site.

Constructed of glass-fiber reinforced polyester (GRP) materials and fabricated with embedded insulation, the Intertec units are sufficiently rugged and waterproof to protect control equipment inside processing areas. Conventional fan cooling and passive cooling techniques can be used.

Given the prevalence of sensitive and critical security equipment, the ThermoTEC Series from EIC Solutions, Inc. features robust, solid-state air conditioners for electronic cabinets with units ranging from 200 BTU to 3,200 BTU. The air conditioners can be installed on an existing cabinet or configured with an EIC Solutions Protector Series enclosure.

Designed in wall/pole mount versions featuring an internal rear sub-panel for mounting equipment or standard 19-inch rack rails, the units are available in NEMA 12, 4, or 4X, and offer a variety of locking latches to secure surveillance equipment. By integrating air conditioning, downtime and failures are minimized, which is crucial for emergency systems. The 4X design of the air conditioners withstands severe outdoor conditions, including dust, dirt, sand, rain, sleet, snow, and corrosion.

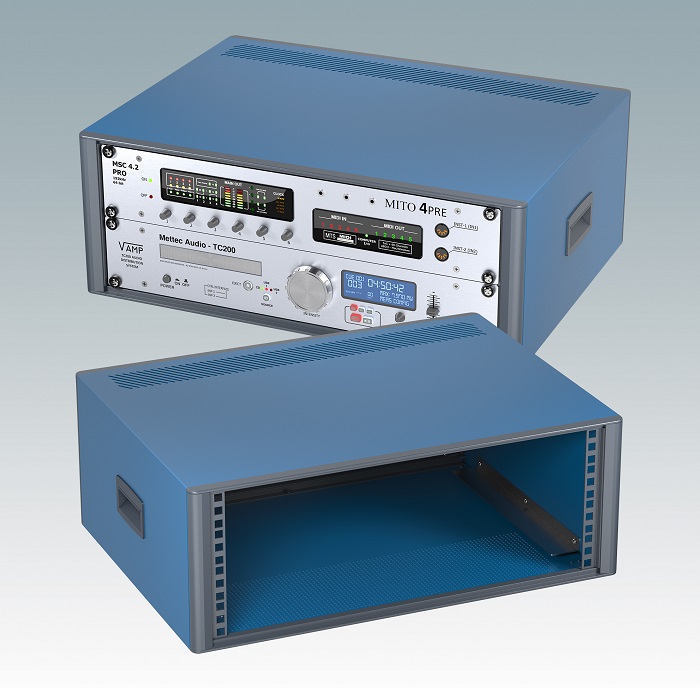

Greater customization is readily seen in METCASE’s advanced TECHNOMET 19-inch mini-rack enclosures that feature a range of options. Used to mount standard 19-inch sub-racks, chassis, and front panels, common applications include test and measurement equipment, networking and communications devices, sound and studio systems, laboratory instruments, industrial computers, and control systems.

METCASE offers TECHNOMET 19-inch enclosures in custom heights of 5U, 7U, 8U, and 9U, as well as in custom depths.

In addition to addressing standard heights of 3U, 4U, and 6U (all 15.74 inches deep) METCASE’s TECHNOMET 19-inch comes in custom heights of 5U, 7U, 8U, and 9U and in custom depths. Other custom options include modified front panels, CNS pinching of holes and cutouts, fixings and inserts, special colors and finishes, and digital printing of legends and logos.

The enclosure features a ventilated base and rear panel as standard. The recessed rear panel (supplied) and front panel (accessory) can be machined for connectors, switches, and other components.

Manufacturers are also adding a wide range of configurations to their enclosures. Hammond Manufacturing, for example, introduced 36 new configurations to its Industry 4.0 1554 and 1555 sealed enclosure lines. Six new sizes include 4.13 x 4.13 x 2.36 and 3.54 inches (105 x 105 x 60 and 90 mm), 5.51 x 5.51 x 2.36 and 3.54 inches (140 x 140 x 60 and 90 mm), and 7.10 x 7.10 x 2.36 and 3.54 inches (180 x 180 x 60 and 90 mm). Polycarbonate versions are cUL- and UL 508A-listed and are tested to IP68 (NEMA Type 4, 4X, 6, 6P, 12, and 13).

A total of 36 new configurations join Hammond Manufacturing’s IP68 1554 and 1555 Industry 4.0 families.

Enclosure sealing is provided using tongue-and-groove construction to protect against oil, dust, and water, and a one-piece UL-listed silicone gasket. The lid is secured with self-captivated M4 stainless steel machine screws that are threaded into integral stainless-steel bushings for repetitive assembly/disassembly. The polycarbonate versions are UV-stabilized for outdoor use. The gray material provides a UL94-5VA flammability rating, and the clear and smoked lids are rated UL94V-0. The ABS versions for indoor use offer a flammability rating of UL94-HB.

In addition, connectivity options are becoming more common. Pixus Technologies recently added a 6U OpenVPX chassis platform with VITA 66.4 optical connectors and VITA 67.3 RF connectors. The OpenVPX connectors are pass-through for versatility in development, while the backplane can be loaded to a variety of requirements. The chassis includes a modular power supply for up to six VPX voltages. Card guides that accept conduction-cooled boards are optional.

L-com announced new wall-mount racks, rack cabinets, floor racks, and rack accessories for LAN, MDF/IDF, data center, and IT connectivity applications. Targeting cable and equipment storage and management, the wall-mount cabinets and racks feature cold-rolled-steel construction and a powder coat black matte finish. The company's wall-mount cabinets and wall-mount racks are available for immediate shipment.

The availability of more configurations and options benefits designers by reducing engineering time and speeding time to market, while reducing overall costs. Expect to see more box builders offering designs that can be configured to meet designers’ exact requirements for security, environmental conditions, and connectivity.

Advertisement

Learn more about Electronic Products Magazine