BY YUSUKE TANAKA, Product Engineer, & YOSHIYUKI TABATA, Senior Product Engineer

Murata Manufacturing

www.murata.com

In recent years, sensor networks intended for monitoring and controlling facilities or equipment, or observing environments or spaces, have been drawing a lot of attention. A sensor network will have a number of sensor nodes, a power supply, and communication functions. The collection of information from a node is done through wired or wireless connections. A sensor network is often the right technology for machine-to-machine (M2M) connections, home energy management systems (HEMS), building energy management systems (BEMS), industrial monitoring and control, and, of course, the Internet of Things (IoT).

Wireless sensor nodes: configurations and problems

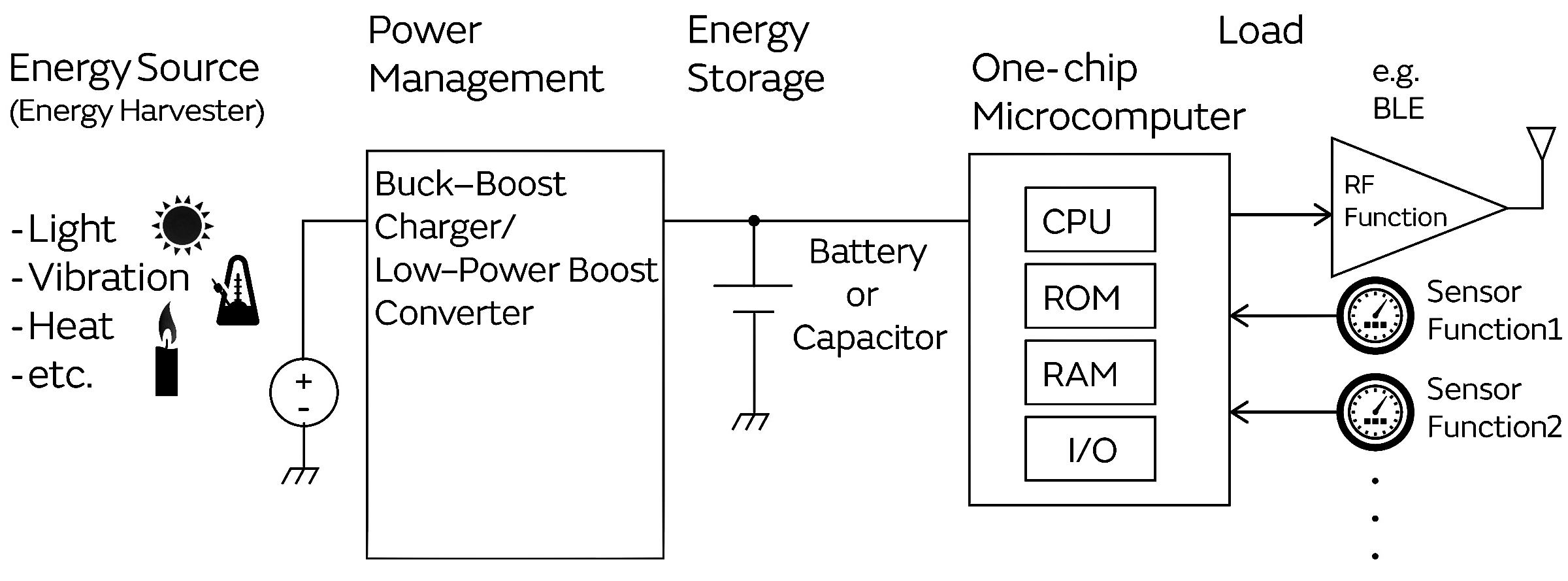

A wireless sensor node needs to have a power storage device, a sensor, a wireless communication chip, an antenna, and a microcontroller and needs to continue operating independently after installation until the battery runs out.

Fig. 1: Diagram shows an example configuration of a wireless sensor node.

Typical power storage devices include electric double-layer capacitors and primary or secondary batteries. Primary batteries are non-rechargeable and come in manganese, alkaline manganese, silver oxide, and lithium versions. Secondary re-chargeable battery types include lead, nickel-cadmium, nickel-hydride, and lithium-ion. Batteries store energy electrochemically, in which chemical reactions release the electrical carrier. A large-capacity capacitor, such as an electric double-layer capacitor or supercapacitor, can also be used and can be charged repeatedly.

If primary batteries are used as power storage devices, it is possible to build a system at a relatively low cost, but it is necessary to periodically replace batteries, and it involves predicting the amount of battery power consumed. If the sensor node is extremely low-power, the battery may last for 20 years and not be a problem. However, particularly in a sensor network with a larger scale and a larger number of wireless sensor nodes configured, that’s not often the case and maintenance for battery replacement becomes a big issue. In particular, a wireless node will not use a primary cell because the transmission power required is quite high and the node would have a very short lifetime without a huge primary battery.

Solutions for energy supply

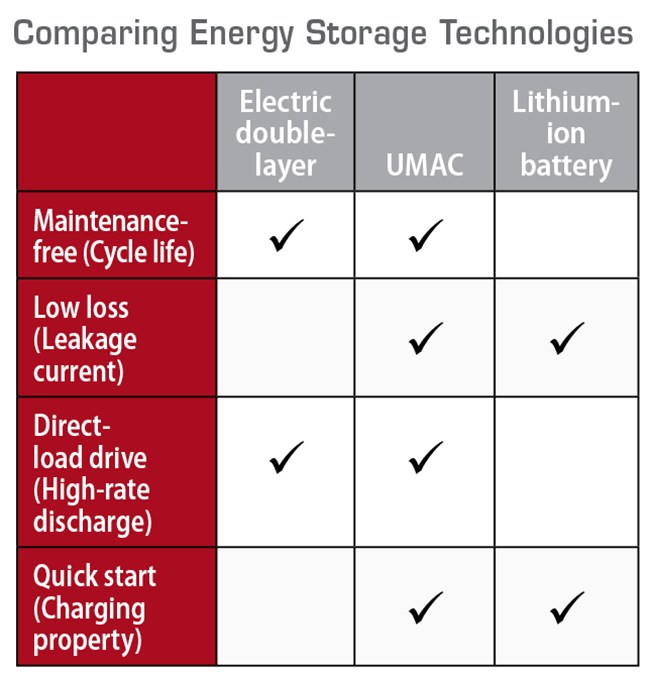

In recent years, attempts have been made to develop energy harvesting with a rechargeable storage device. Power generation devices that use natural energy, such as sunlight, vibration, and heat, are being used. But, of course, devices capable of being incorporated into small devices can secure only a small amount of power. The power storage device used needs to be capable of being fully charged, even by a low capacity source, and retaining energy for a long period without leaking it. Also, the storage device’s performance needs to be maintained even after it is charged and discharged many times. Secondary batteries and electric double-layer capacitors of different types have advantages and disadvantages, and currently, only a small number of these devices can satisfy all conditions suitable for energy harvesting.

Application to wireless sensor nodes

The supercapacitor offers some big advantages. It uses physical charge separation phenomena between charges on electrodes and ions in electrolyte at the interface. They can release energy much faster than a battery and can be cycled hundreds of thousands of times without largely affecting performance. Meanwhile, the energy density of a supercapacitor is much less than that of a lithium-ion battery — at least 20 times less. There are many supercapacitor/electronic double-layer capacitors available — manufacturers include Murata, Taiyo Yuden, Illinois Capacitor, Vishay, NIC Components, Maxwell Technologies, KEMET, Cornell Dubilier, Nichicon, Eaton, AVX, Panasonic, and Elna.

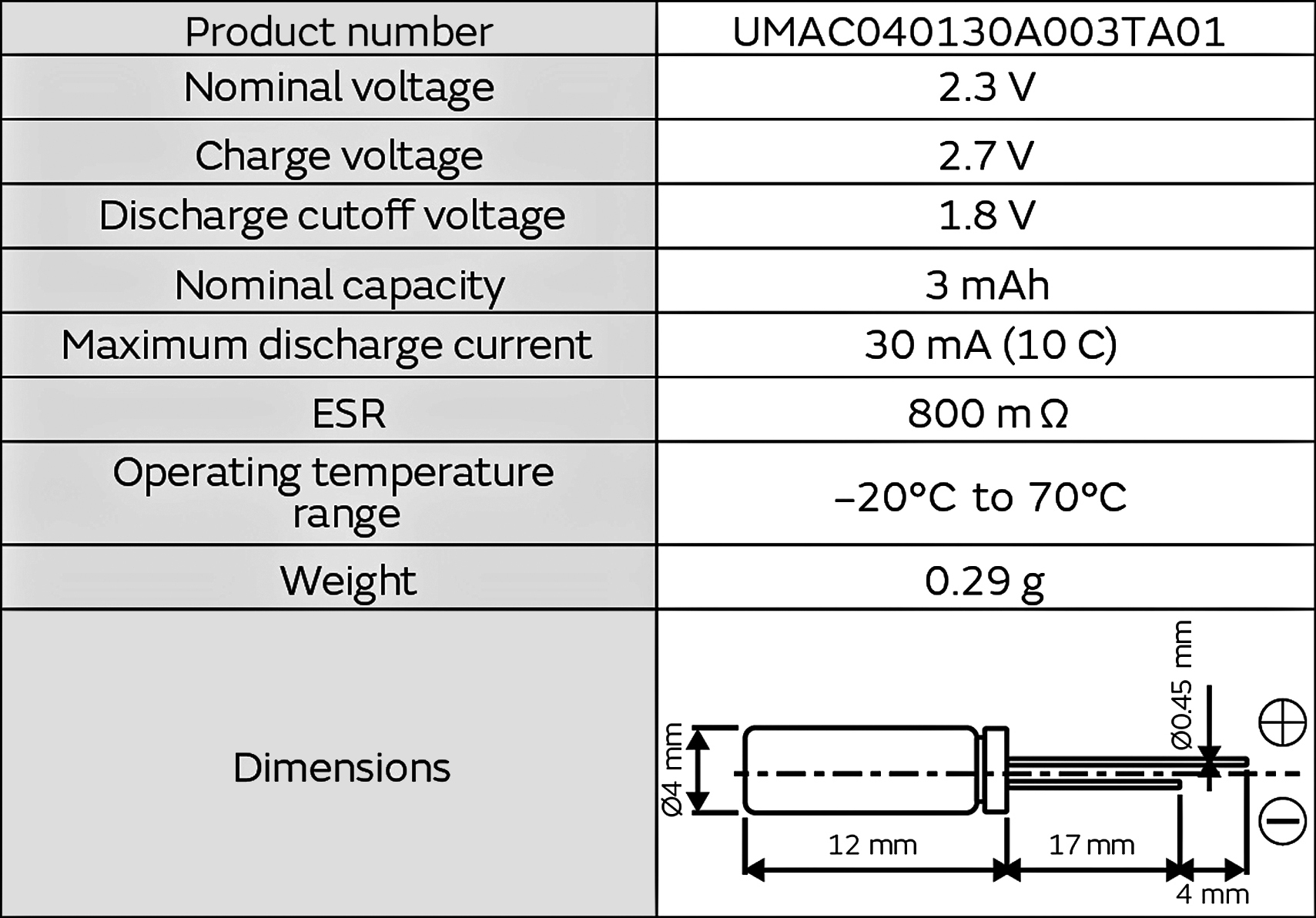

In a variation on the supercapacitor and the storage battery, Murata Electronics makes a small energy device called UMAC (UMAC040130A003TA01). It is a lithium-ion secondary battery that uses lithium titanate as cathode material, unlike conventional lithium-ion batteries. Its design allows high- or low-rate charging and discharging, long lifetime, and improved levels of safety.

Fig. 2: Basic UMAC specifications.

Fig. 2 shows the product specifications of UMAC. It comes in a single size with a capacity of 3 mAh, a nominal voltage of 2.3 V, and a maximum continuous discharging current of 30 mA (10C). UMAC has a 10-times-larger power density and about the same energy density as a general-purpose lithium-ion battery. It is suitable for space-saving applications requiring a power supply of up to 30 mA. Also, normally, when a lithium-ion battery is charged, it is necessary to control charging current for safety reasons, and it takes a longer time to charge. UMAC does not require careful control of current during charging, can be charged at a constant current, and is suitable for applications requiring quick charging. The UMAC does have a somewhat high ESR of 0.8 Ω compared to some supercapacitors, which limits its discharge rate or power density. This may be more of an advantage than a disadvantage in many cases.

Requirements for wireless sensor node power storage

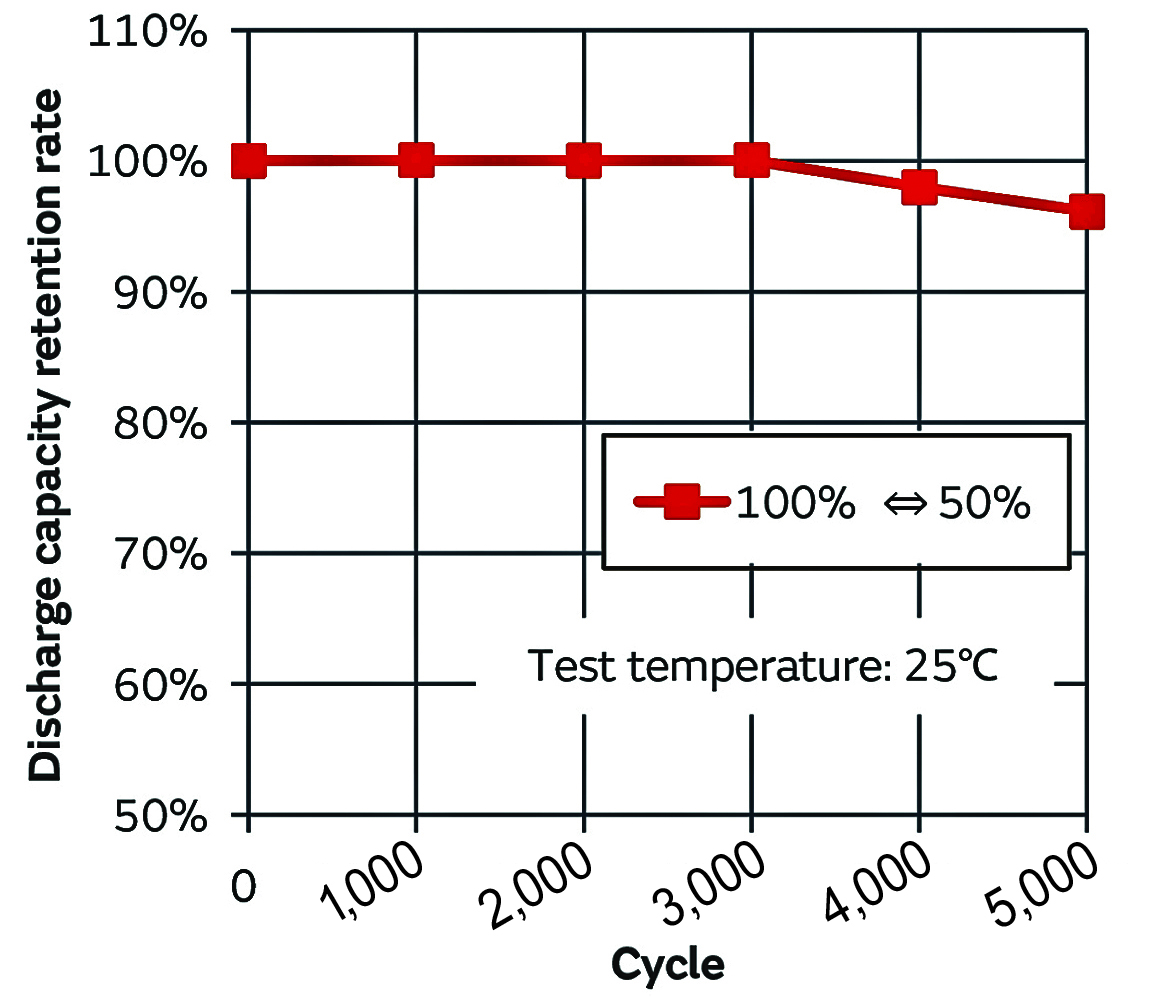

Power storage devices for wireless sensor nodes require four properties. The first property is a long cycle lifetime to eliminate the need for the regular maintenance. Fig. 3 shows discharging capacity retention rates against charge/discharge cycles for the UMAC device. If the discharge amount for one cycle is 50%, then 90% or more of the capacity is maintained after 5,000 charge/discharge cycles. If the discharge amount is less than this, the cycle lifetime further increases. If discharge is performed once per day, 5,000 cycles are equivalent to about 13 years and, therefore, UMAC should be able to contribute to the development of maintenance-free sensor nodes.

Fig. 3: UMAC capacity rates after many charge/discharge cycles.

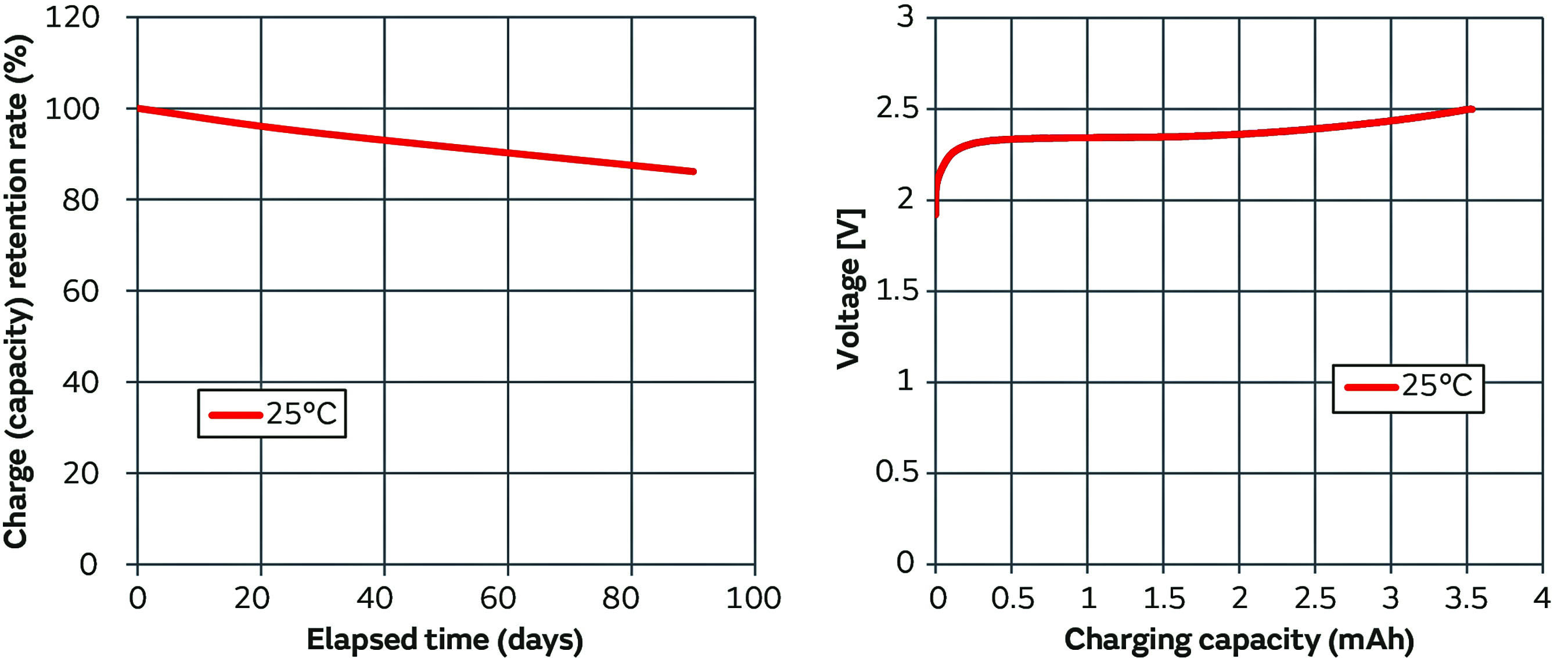

The second property is the capability to charge even from weak current sources and to retain energy for a long time. Energy-harvesting devices often provide low current at relatively high impedance. The retention of generated scarce energy for a long time without leaking it is required. In Fig. 3 , we show charge capacity retention rates. The UMAC device retains 88% of the capacity after left untouched for 90 days from the time it is fully charged, and its leakage current is calculated to be approximately 0.17 μA. It can be fully charged even using a very low current of 5 μA.

Fig. 4: UMAC long-term capacity retention and 5-μA charging properties.

The third property that may be required is that of fairly high-rate discharging. If a power storage device can be charged adequately but cannot meet the peak load of the system, peak assist devices such as capacitors will be required, making the system complicated. The UMAC can discharge at up to 30 mA (10C), and so it can be used as a power source for near-field communication such as Bluetooth Low Energy (BLE) and ZigBee to directly drive a load. The device is also effective at low temperatures, unlike lithium-ion batteries, and thus can be used outdoors in cold climates. UMAC can handle quick pulse discharges, even at low temperatures.

The fourth required property is the capability to be used immediately after charging begins. In a capacitor, the amount of charge stored is proportional to the voltage between both ends of the capacitor and, therefore, there is a time lag between when charging starts and when the system becomes operational. In contrast, UMAC allows the system to become operational immediately because it is a lithium-ion battery and will reach its nominal voltage of 2.3 V when charged to only several percent.

Advertisement

Learn more about Murata Electronics North America