The rate of change in high speed interfaces is quickening. Answering customer requests for faster and more reliable data, key sectors — including industrial, automotive, and consumer electronics — are introducing new products and solutions.

As an example, in the industrial sector, advancements to assembly line technology, ranging from smarter robots to entire Industrial Internet of Things (IIoT) solutions, have been made to improve production workflow. Companies employing these advancements are able to achieve low costs, higher reliability, and faster time to market.

In the automotive market, collision avoidance technology, connectivity, and the path towards “hands off” driverless technology are redefining the need for reliability in the automotive electronics market. Today’s vehicles are significantly more advanced than the vehicles marketed even five years ago. They are outfitted with a host of sensor technologies to make the car a smarter machine, and more efficient in its operations.

In consumer electronics, today’s general consumers expect devices to always be connected, and to that end, immediately responsive to requests for information. Mobile gadgetry, coupled with the dawning of the IoT era, has led to a demand for a new type of “always-available” electronic gadgetry.

To ensure these electronic devices, machinery, and solutions are reliable, efficient, responsive, and accurate, the systems within these technologies must be able to operate at peak performance. The components must be protected from ancillary effects that could damage them and adversely impact the technology’s performance.

Among the more susceptible components are the high-speed interfaces in many modern-day electronics, including HDMI connections, USB ports, Thunderbolt ports, and many more. If not properly protected from damage caused by, say, electrostatic discharge (ESD), it could lead to a breaking down of the interface itself, which, in turn, could lead to the application as a whole failing.

Using ESD as an example, some of the more common problems that it can cause to an (IC) integrated circuit include excessive leakage current prematurely draining a portable Li-ion battery, unreliable signal integrity causing data transfer errors, and in some case outright failure of the host IC to function at all. More often than not, this can be chalked up to the technology being outfitted with limited ESD protection.

Littelfuse, the industry’s leader in circuit protection solutions, addresses all of these issues and then some, to allow high-speed interfaces to meet system expectations. Case in point: the company’s new silicon-enhanced ESD (SESD) series. It provides in excess of 20-kV contact ESD protection, well beyond the maximum requirement of 8kV as defined by the IEC61000-4-2 specification, which is what the electronics industry relies on for proper procedures in ESD testing equipment and systems for ESD immunity.

In addition to covering the most basic interface-ESD needs, the company’s SESD products also consider signal integrity (SI). In short, a system or data bus will transmit a series of 1s and 0s, and if the SI is operating properly, it’ll read exactly the same from the point it leaves the transmitter to when it reaches the receiver. If it’s not functioning properly due to damage from ESD, the device will not be able to transmit or decode the 1’s and 0’s accurately, or its delivery of data could be delayed. To ensure SI is not adversely affected by ESD, Littelfuse’s SESD solutions offer ultra-low capacitance ESD protection in either unidirectional or bidirectional configurations, thereby providing design choice without sacrificing level of protection or SI.

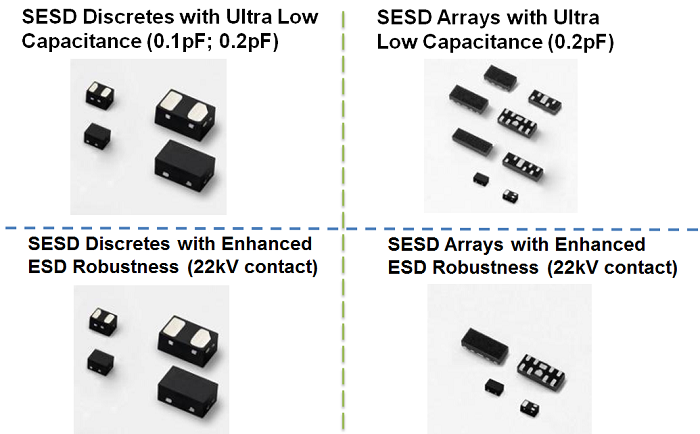

Littelfuse’s SESD products also take into consideration the footprint of these components; specifically, they should be as small as possible. Four key products comprise the SESD family:

• SESD Discretes with Ultra-Low Capacitance (0.1 pF; 0.2 pF)

• SESD Arrays with Ultra-Low Capacitance (0.2 pF)

• SESD Discretes with Enhanced ESD Robustness (22kV contact)

• SESD Arrays with Enhanced ESD Robustness (22kV contact)

Each one has different options featuring different specs, to match the design of the device’s interface and occupy as little real estate as possible. This way, protection is maximized with very little added system cost, complexity, and attenuation.

A summary of some of the key features of the Littelfuse SESD products:

• 0.20pF TYP capacitance

• ESD, IEC61000-4-2, ±20kV contact, ±20kV air

• Low clamping voltage of 9.2 V @ IPP=2.0A (tP=8/20μs)

• Low-profile DFN array packages

• Facilitates excellent signal integrity

• AEC-Q101 qualified (1004)

• ELV compliant

Applications for the SESD products:

• USB 3.1, 3.0, 2.0

• HDMI 2.0, 1.4a, 1.3

• DisplayPort

• V-by-One

• Thunderbolt (Light Peak)

• LVDS interfaces

• Consumer, mobile and portable electronics

• Tablet PC and external storage with high-speed interfaces

• Applications requiring high ESD performance

To meet consumer expectations for robust products and efficient solutions, ESD protection is of the utmost importance. Fortunately, Littelfuse offers a roster of ESD solutions to enable this next generation of high-speed and high-power technologies.

To learn more, go to arrow.com

Advertisement

Learn more about Electronic Products Magazine