For many electronic devices, performance characteristics are impacted by temperature. Too much heat can lead to component malfunction or premature component failure. For instance, a major cause of light-emitting-diode (LED) failure is an elevated junction temperature. The junction of an LED, where two types of semiconductors are joined together, is known to be a hot spot, because both heat and light are emitted as electrical energy is consumed. As the junction temperature increases, light output decreases and the color shifts toward blue. Products such as television displays, handheld electronic device displays, electronic signs, and daylight automobile headlights depend on LEDs to generate reliable light.

Excessive heat threats

For LEDs as well as transistors and other semiconductor electronic components, failure to stay below specified temperature limits, such as maximum junction temperature or maximum case temperature, may result in irreversible damage and permanent performance shifts. Waste heat produced by high currents in power transformers and power handling semiconductors can cause these devices to overheat, potentially compromising performance. Heat must be removed in order to maintain operating temperatures within specifications and ensure component reliability.

Meeting temperature specifications has become a major challenge in recent years, as more functionality is being squeezed into ever shrinking packages. State-of-the-art 22-nm process geometries make it possible to create integrated circuits (ICs) with transistor densities in excess of 8 million transistors per square millimeter. Higher transistor density means less surface area for heat dissipation — and even hotter hot spots — on microprocessors and other high-performance chips. In addition, miniaturized components are often packaged in space-saving IC chip carriers, such as chip-scale packages and ball-grid arrays (BGAs), confining the heat to tiny enclosures. Tighter packaging technologies, such as system on a chip (SOC), in which components are stacked on top of one another, also exacerbate the heat dissipation issue.

Managing heat by design

Efficient thermal management has become a top priority in modern electronic design and packaging. Heat must be removed at the die, component, and substrate level in such a way as to balance performance, reliability, cost, and, in some cases, weight. There are three modes of heat transfer: conduction, convection, and radiation. The goal of thermal management is to determine a cost-effective, efficient path for transferring heat from the device to the environment using one or more heat transfer techniques.

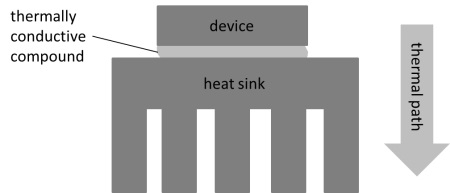

Heat sinks are commonly used to transfer thermal energy away from microprocessors, power transistors, LED arrays, and other devices into the surrounding air (see Fig. 1 ). Usually made of an aluminum alloy or other metal, a heat sink consists of a flat surface with fins or other protrusions designed to increase its surface area. The flat surface is placed in contact with the electronic device so that heat flows from the device to the heat sink, is conducted through the heat sink, and is convected to the surrounding air. The amount of heat transferred via convection is proportional to the surface area at the transfer point, so the heat sink’s extensive surfaces greatly increase the amount of heat dissipated into the air.

Fig. 1: Heat sinks transfer heat away from power devices into the surrounding air.

Special materials transfer heat

Specially formulated thermal interface materials (TIMs) are often applied between the heat-generating device and the heat sink to fill in thermally insulating air gaps and maximize heat transfer efficiency. A TIM is characterized by its thermal conductivity (see sidebar ), which typically exceeds 0.3 W/mK — more than 10 times higher than that of air (0.022 W/mK). Since metal heat sinks are better thermal conductors than TIMs, optimal thermal efficiency is achieved by minimizing the thickness of the TIM and eliminating excess material.

Thermal greases, phase change materials, and thermally conductive epoxies are some of the many varieties of thermal interface materials available on the market today. Selection of an appropriate TIM for a particular application depends upon application parameters such as power density, processing requirements, reworkability, and other concerns. Thermally conductive epoxies are often preferred over other alternatives because they provide attachment and other functionality in addition to heat transfer capabilities. These multifunctional systems offer size and weight advantages over solutions that require mechanical attachment and stability, as well as other benefits.

Performing multiple functions

Thermally conductive polymer compounds consist of epoxy, silicone, or elastomeric formulations filled with thermally conductive metal, ceramic, or nanotech particles. Typical conductivity values range from 1.5 to 3.0 W/mK, with conductivity reaching as much as 4.0 W/mK for some specially formulated grades. For a given type of filler, formulators can achieve higher thermal conductivity values by increasing the concentration of filler particles. There is a trade-off, however, with bond strength, since more filler means fewer polymer molecules available for cohesion. This trade-off is not an issue for most electronics applications since bonded electronic components are typically not subjected to high forces.

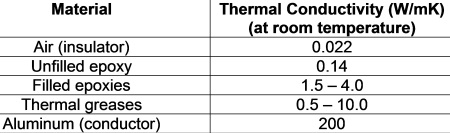

Table 1: Bulk thermal conductivities of common materials

Adhesives and related compounds are known for their ability to balance a variety of physical, electrical, and mechanical properties. Formulators tailor properties to suit specific applications through selection of resin and hardener, filler type and concentration, and other additives and by controlling the degree and method of curing. Thermally conductive epoxy systems offer chemical and moisture resistance, and include grades that are cryogenically serviceable as well as grades that resist temperatures in excess of 500°F. Grades that are designed to protect electronics from shock and vibration, in addition to managing heat, are also available, as are formulations that can withstand thermal cycling and grades that meet NASA low-outgassing standards. One- and two-part compounds with different viscosities, moduli, and cure schedules, as well as epoxy films, offer engineers a variety of application options.

Fig. 2: High thermal conductivity, minimal bond line thickness, complete polymerization, and elimination of voids help minimize the thermal resistance along the thermal path.

Cure conditions can impact the thermal conductivity of an adhesive compound. Too low a cure temperature can result in a slow cure and lower crosslink density, while too high a cure temperature can produce high exotherms that may cause the adhesive system to expand. Optimal conductivity is achieved when complete polymerization occurs through a cure schedule recommended by a knowledgeable formulator. With a complete cure, the thermally conductive filler particles come into contact with each other, facilitating more efficient heat conduction.

Careful application of a thermal product is essential for efficient heat transfer. As illustrated in Fig. 2 , uniform, thin bond lines and elimination of air gaps are important in order to create a thermal path with the lowest possible thermal resistance (see sidebar), permitting heat to flow efficiently from a hot device to a cooler medium.

Thermally conductive epoxies are commonly used for the dual purpose of bonding and transferring heat in applications such as high power semiconductor die attach, heat sink attach, and staking temperature sensitive components to printed circuit boards (PCBs). They are also used as a thermal bonding interface between the die and the heat spreader in BGA packages. Although most thermally conductive epoxies are electrically insulative, some grades combine thermal and electrical conductivity through the use of metal fillers and can be used as an electrical ground on a PCB. Related thermally conductive potting compounds are used to transfer heat away from transformers, coils, and power supplies while protecting them from shock, vibration, and other environmental conditions. Thermally conductive epoxies can also function as sealants to protect sensors, connectors, and pins while managing heat.

Extending component life

Today’s high-performance electronic devices are squeezing more functionality into tighter packages. Market demand for performance improvements and advanced features translates into increased power requirements — fueling higher heat outputs. Efficient heat removal is a must in order to prevent premature component failure and extend product life.

Thermally conductive compounds help optimize heat transfer across interfaces in a variety of applications in multiple industries. By providing attachment, environmental protection, and other functions in addition to heat transfer, these adhesives, sealants, and potting compounds are enabling smaller, increasingly powerful electronic systems.

Sidebar:

Thermal conductivity and thermal resistance

Thermal conductivity quantifies a material’s ability to transfer heat via conduction. Often denoted as κ, thermal conductivity is defined as the amount of heat energy transferred across a known sample area in a given amount of time when a temperature gradient is applied across the sample. Common units of thermal conductivity are:

The inverse, or reciprocal, of thermal conductivity is thermal resistivity. Thermal resistivity (1/ κ) characterizes a material’s ability to oppose the flow of heat. Both thermal conductivity and thermal resistance are functions of temperature, and both are fundamental material properties; that is, they are independent of the specific device or its geometry. In real world applications, thermal conductivity is important, but not sufficient in assessing thermal performance, because the geometry of the specific device is also an important consideration. The efficiency of heat transfer is best determined by considering the thermal resistance of a specific object.

Thermal resistance (R) measures an object’s resistance to heat flow, and is determined by both its thermal resistivity and its geometry. The thermal resistance of an object is a ratio of the difference in temperature to the power dissipated, and can be expressed as a function of the object’s geometry and thermal resistivity:

where L is the thickness of the object, A is its surface area, and κ is its thermal conductivity. This relationship illustrates that as surface area increases, thermal resistance decreases (which is the key principle behind heat sinks), and that as thickness increases, thermal resistance increases. For thermally conductive adhesives used to bond heat sinks to electronic components, optimum heat transfer is achieved by minimizing bond line thickness. In some cases, the size of the filler particles in a thermally conductive epoxy dictates the minimum bond line thickness that is achievable without sacrificing bond strength. Typical particle size is 40 μm,but Master Bond has developed proprietary fillers that measure just 3 μm across — improving heat transfer capabilities without compromising bond strength.

For the most efficient heat transfer, the total thermal resistance of the path from the heat generating device to the cooling medium — the air surrounding a heat sink, for instance — should be minimized. This is achieved by selecting a thermally conductive compound with high thermal conductivity, curing to completion, ensuring adequate wetting and bond line uniformity, minimizing bond line thickness, and eliminating air gaps in the bond line.

Advertisement

Learn more about Master Bond