Formulated to meet rigorous Airbus specifications, Master Bond EP93FRHT passes the twelve second vertical burn test per AITM 2.0002B and Section 7.1.2 of ABD0031, Issue F; the smoke emission test per AITM 2.0007B, Issue 3 in the flaming mode and Section 7.3.2 of ABD0031, Issue F; and the toxic gas emission test per AITM 3.0005, Issue 2 in the flaming mode and Section 7.4 of ABD0031, Issue F. “These tests focus on how quickly EP93FRHT will self extinguish when subjected to a vertical burn test, and minimizes the optical density of the smoke emitted as well as the toxic gas emitted in the smoke,” said Rohit Ramnath, senior product engineer. “This epoxy system excels in all three criteria.”

This specialty non-halogenated system can be used for bonding, sealing and encapsulating applications in aircraft requiring stringent Airbus specifications be satisfied. It is most likely to be used in the assembly of interior panels, floor and doors, as well as frame lining. Featuring reliable electrical insulation properties, EP93FRHT also can be used for potting electronic components across various industries.

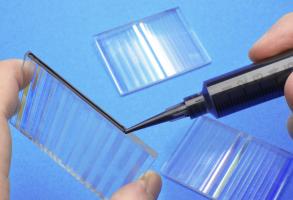

EP93FRHT has a moderate mixed viscosity of 6,000-9,000 cps and a one to one mix ratio by weight. Mixing is further facilitated through color coding, as Part A is black, Part B is off-white and the cured material is dark gray. For optimal performance properties, the recommend cure schedule is overnight at room temperature followed by 3-5 hours at 150-200°F. EP93FRHT has low shrinkage upon curing and bonds well to a variety of substrates including metals, composites, glass, ceramic and many plastics. This system delivers excellent thermal cycling capabilities over the wide service temperature range of -80°F to +400°F. It also has good chemical resistance to water, fuels, oils and many common solvents.

This system is available for use in ½ pint, pint, quart, gallon and 5 gallon container kits, as well as premixed and frozen syringes.

Advertisement

Learn more about Master Bond