BY CHRISTOPHE WAELCHLI

Product Manager, Hearing Health, Consumer Health and Portable Audio, Medical and Wireless Product Division

ON Semiconductor

www.onsemi.com

There are few applications facing more technical constraints than modern hearing aids. Here, the demand to boost performance levels and lower power consumption within smaller designs is greater than it is with consumer electronics. This pressure is amplified by the fact that the hearing aid industry is currently growing by 4% to 6% annually (according to several reputable market research firms), fueled by an aging population and new markets developing in China and India. As such, there is a necessity to fit a broader range of patients with improved functionality.

By integrating more sophisticated digital signal processing (DSP), semiconductor solutions will enable manufacturers to meet these needs of hearing aid users. The following article details the various design considerations influencing DSP technology and its implementation within today’s hearing aids.

Putting it simply, a hearing aid device works as follows. Sound waves are received by the microphone and translated into an analog electrical signal. An analog-to-digital converter takes this analog signal and turns it into a digital signal. DSP algorithms are then used to process and condition it. The digital signal is then returned to its analog form, before being passed through the receiver and transformed back into sound waves, which are heard by the hearing aid user. In order to minimize the visual impact of these devices and improve the comfort of the person wearing them, new models that are much more discrete than before are being introduced. Commonly used behind-the-ear (BTE) devices are now starting to be replaced by hearing aids that are located deeper within the ear canal, such as completely-in-canal (CIC) and invisible-in-canal (IIC) devices, or by miniature over-the-ear devices (also called mini-BTE or OTE). This trend of a hearing aid being “heard but not seen” requires wholesale system miniaturization right down to the integrated circuit.

Need for customization

OEMs are now looking for IC solutions through which they can realize their own unique algorithms for processing hearing aid data signals. This will permit a more efficient ‘platform’ strategy to be put in place, with various hearing aid models being created from the same core DSP. For example, mild hearing loss can be addressed by a certain set of algorithms, while high power devices, addressing severe hearing loss, can use the same platform, yet differentiate by additional gain or functionality and performance.

Wireless connectivity

There has been considerable interest in using wireless technology to enable the transfer of audio signals between hearing aids and electronic devices, such as smartphones. Enabled by a 2.4-GHz frequency band (where Bluetooth and ZigBee wireless standards are located), a wireless connection allows hearing aid users to experience audio directly from electronics. For example, the user can stream music from a handheld device, or use the hearing aid as a headset to conduct phone conversations. Wireless connectivity can also improve the interaction between user and device. Using smartphones, hearing aid users can easily adjust and customize parameters and settings (for example, volume control) without the need for cumbersome relay accessories. With no definitive standard for wireless technology, engineers must be able to quickly adapt to emerging standards, like Bluetooth Low Energy.

DSP architecture options

There are a number of different types of DSP architectures that can be employed in modern semiconductors. Since the architecture will have considerable bearing on the overall effectiveness of the hearing aid design, OEM engineering teams should ensure they give serious consideration to the options available, before finally deciding on one.

1. Closed architectures. With a closed, fixed function, architecture the DSP is hardwired directly into the architecture, optimizing the system for both power consumption and size. Unfortunately, this comes at the cost of losing system flexibility. Though a few minor parameters remain adjustable, the fundamental functionality of the IC cannot be changed without major redesign work — which is expensive and time consuming.

2. Open-programmable architectures. Open-programmable architectures provide the OEM with improved design flexibility, as the DSP algorithms can be modified relatively easily. However, this flexibility is accommodated in a larger system, which fails to meet the stringent power and size requirements of modern hearing aids.

3. Semi-programmable and application-specific, open-programmable architectures. lternative architectures are now emerging that are able to combine the favorable attributes of both closed and open-programmable together. In semi-programmable architectures essential DSP functions are hardwired into logic blocks alongside additional programmable DSP elements where extra capabilities can be realized in software. Although this provides some flexibility, semi-programmable architectures still have markedly larger power budgets than closed architectures. Application-specific, open-programmable architectures present another approach. Here the DSP architecture is designed with deep understanding of the application needs and optimized to handle specific signal-processing requirements for a particular application. It has the software programmability of an open-programmable architecture and power efficiencies that are relatively similar to those found in closed architectures, providing the design layout is well executed and a suitable semiconductor geometry is used. Such architectures are facilitating the platform approach that OEMs now desire.

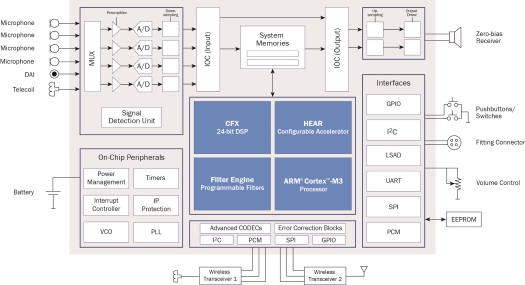

Ezairo 7100 from ON Semiconductor (see figure) is a compact, highly sophisticated system-on-chip (SoC) solution targeted at next generation hearing aid deployment. It incorporates an analog front-end, an ARM Cortex-M3 processor, and a 24-bit quad-core DSP (based on application-specific, open-programmable architecture) onto a single semiconductor die. The hybrid of closed and open-programmable architectural implementations means that the IC draws less than 0.7 mA when operating at its maximum clock speed of 10.24 MHz. This permits a curbing of system power consumption, while still giving engineers the design flexibility necessary (with algorithms being adjustable), to create feature-rich hearing aid designs that stand apart from the competition.

A block diagram of the Ezairo 7100 illustrates the compact, sophisticated SoC solution targeted at next-generation hearing aid deployment.

The technology in the hearing aid industry is in a state of flux — with rapidly evolving innovations to be exploited and emergent markets to be addressed. Strong rivalry and a demand for faster time to market are leading to shorter product life cycles and a need for greater differentiation. Using DSP technology on programmable or application-specific architectures from ON Semiconductor, engineers will create smaller hearing aids that are packed with functionality, improving user comfort and satisfaction.

Advertisement

Learn more about ON Semiconductor